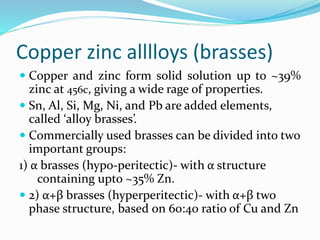

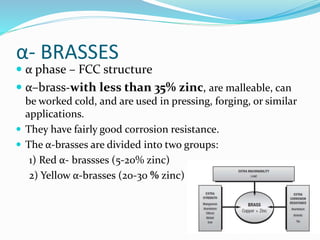

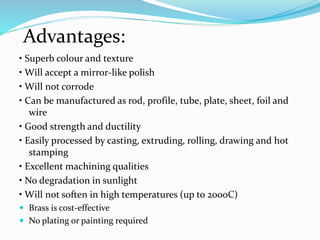

Brass is a metal alloy composed primarily of copper and zinc. By varying the proportions of copper and zinc, the properties of brass can be altered, allowing for harder and softer variations. Brass has a yellow color, higher malleability than bronze or zinc, and is corrosion resistant. It is commonly used in applications that require decorative gold-like appearance, acoustic properties for musical instruments, or corrosion resistance for plumbing fixtures and other uses.