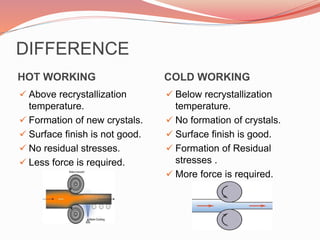

The document discusses metal forming processes used in manufacturing engineered steel and metal components, focusing on hot and cold working methods. Hot working occurs above the recrystallization temperature, allowing for significant deformation with advantages such as higher ductility but disadvantages like poor surface finish. Cold working, performed below this temperature, offers better dimensional control and improved mechanical properties but requires greater force and equipment.