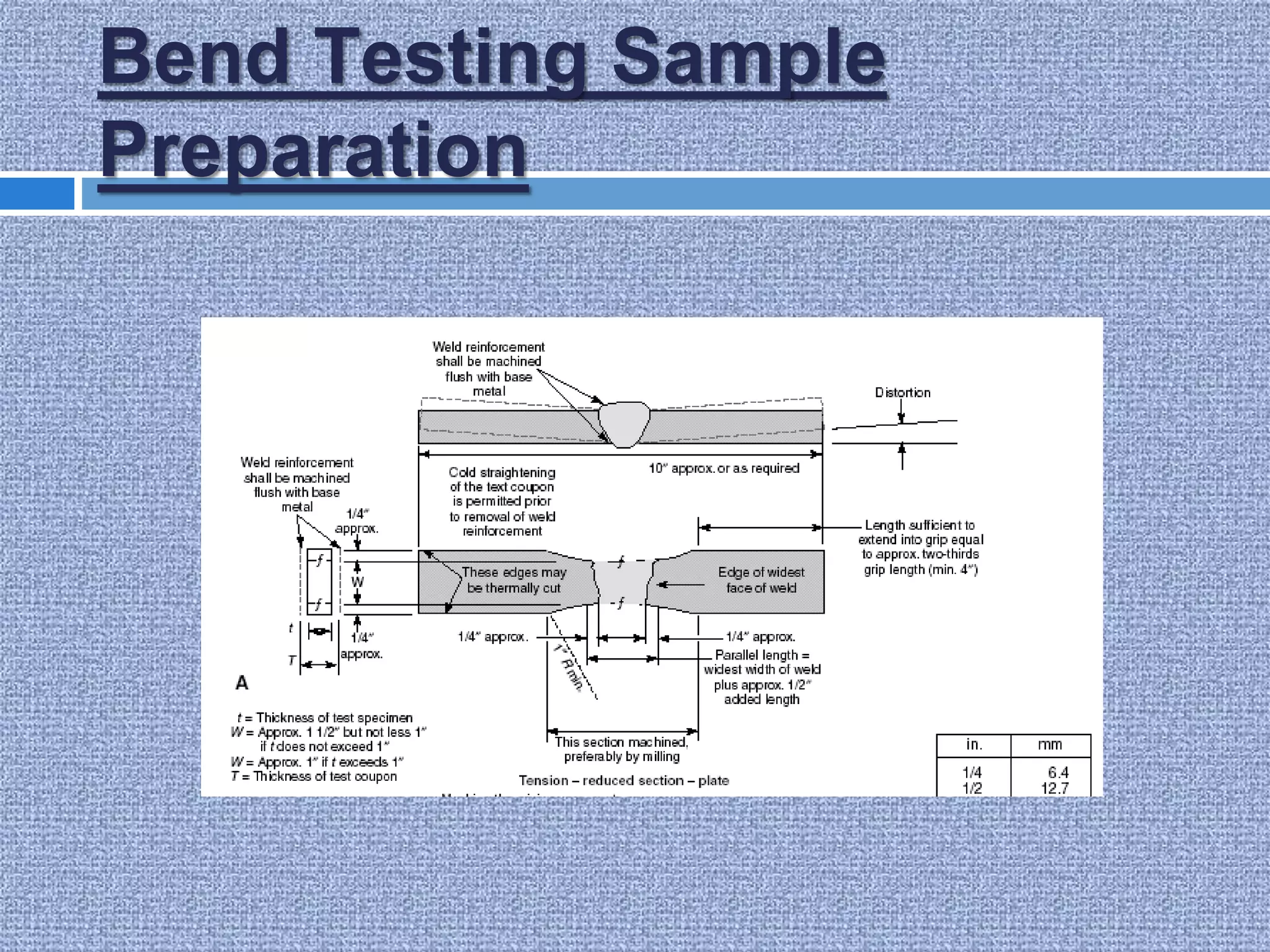

This document describes bend testing procedures for evaluating the ductility of welds. It discusses different types of bend tests including guided bend tests, where a mandrel forces the specimen between supports, and free bend tests. It explains that guided bend tests are primarily used for plates. The document also outlines how to prepare bend test samples in different orientations like transverse face, root, and side bends as well as longitudinal face and root bends. Finally, it states that bend testing can show the tensile strength, ductility, and fusion/penetration of welds.