The document provides an overview of the Taguchi Method, which was developed by Genichi Taguchi in the 1950s to help improve quality in manufacturing. Some key points:

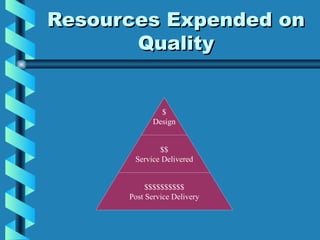

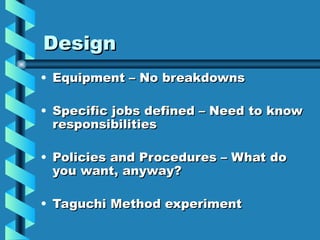

- Taguchi focused on designing products and processes to be robust to sources of variation, eliminating non-random errors upfront to reduce quality losses.

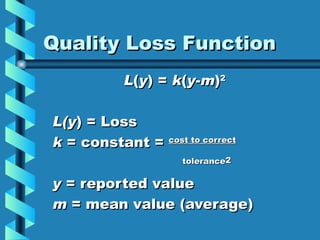

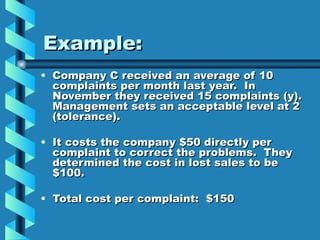

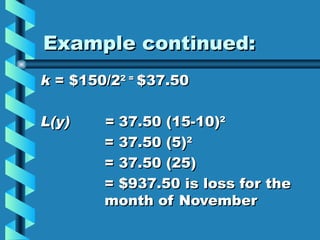

- Quality is defined as how well a product meets customer needs. Variation from the optimal target results in losses that can be quantified using a quality loss function.

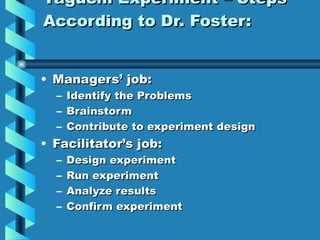

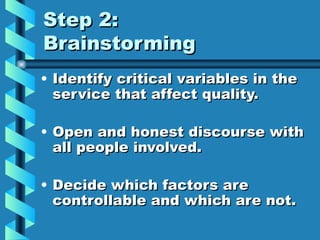

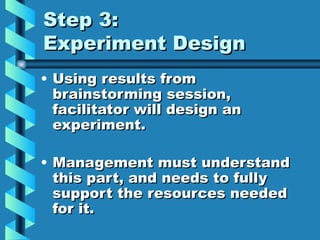

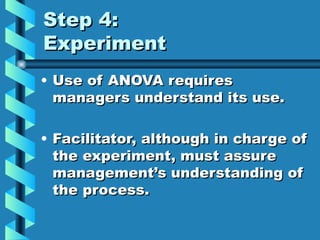

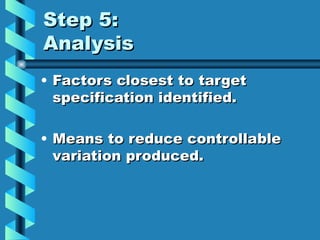

- The Taguchi Method uses designed experiments to determine which factors most impact quality and find ways to control variation. A 6-step process is outlined for identifying problems, designing and running the experiment, and validating results.