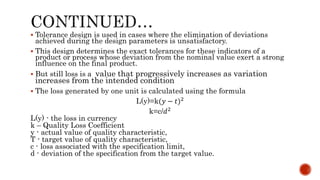

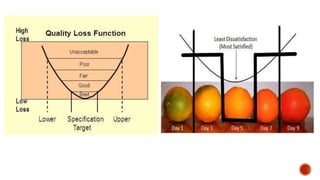

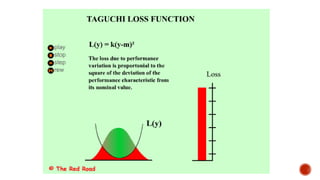

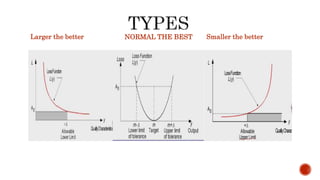

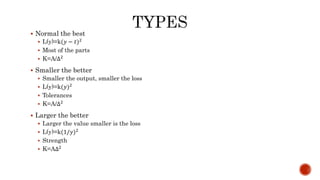

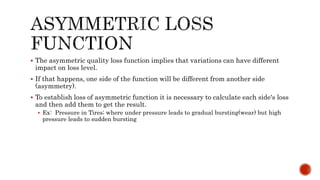

The document discusses quality loss and the Taguchi loss function. It explains that the Taguchi loss function graphically depicts how small variations within specifications can exponentially increase customer dissatisfaction. There are controllable and uncontrollable factors that influence product quality. The Taguchi method aims to select controllable factor levels that minimize sensitivity to uncontrollable interference. It also discusses parameter design, tolerance design, and formulas for calculating quality loss based on the deviation from the target value.