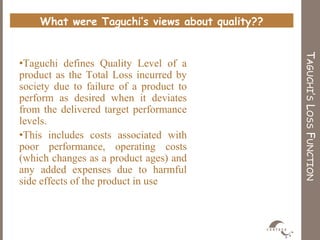

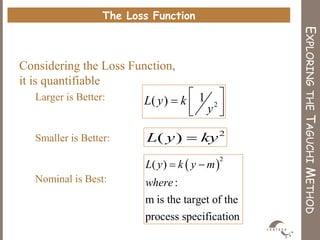

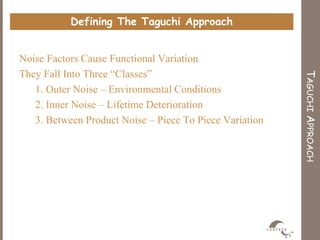

This document summarizes Taguchi's views on quality engineering and analysis. It discusses Taguchi's definition of quality as the total loss incurred by society due to product failure or deviation from desired performance levels. This includes costs of poor performance, operating costs over the product lifespan, and harmful side effects. The document also explains Taguchi's loss function approach, which quantifies quality losses based on the product's deviation from the target value. It provides an example showing how to calculate annual losses and how improving the process mean and reducing variation can significantly reduce quality losses. Finally, it outlines the key aspects of Taguchi's approach, including designing quality in at the system, parameter, and tolerance levels to produce robust products and processes insensitive to variability