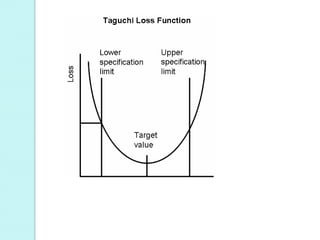

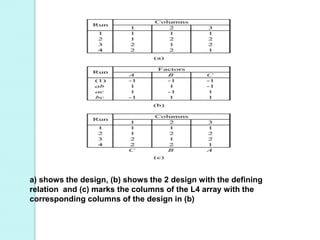

Genichi Taguchi was a Japanese engineer known for developing quality engineering and loss function methodologies. He developed statistical methods to improve product quality and reduce costs, including quality loss functions and orthogonal arrays. Quality loss functions graphically depict how deviations from a target value result in losses, with losses increasing quadratically as deviation increases. This approach aims to minimize total losses by reducing variability from the target. Orthogonal arrays are experimental designs that allow investigation of many factors using few experimental runs. Taguchi's work aims to improve quality without increasing costs by reducing variability from targets.