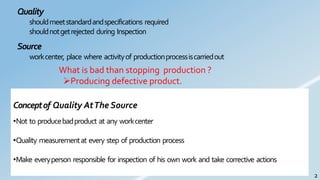

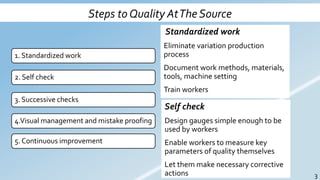

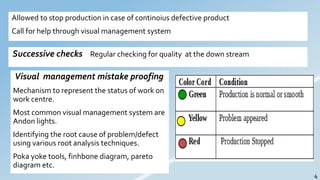

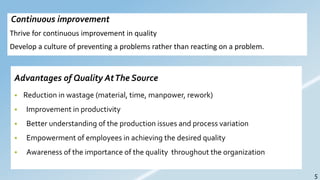

Quality at the source is a manufacturing philosophy where quality is built into each step of the production process and workers are responsible for inspecting their own work. It involves standardizing work, self-checks by workers using simple gauges, successive checks of quality down the production line, visual controls to identify issues, and continuous improvement efforts. Implementing quality at the source reduces waste and rework, improves productivity, empowers employees, and creates a quality-focused culture across the organization.