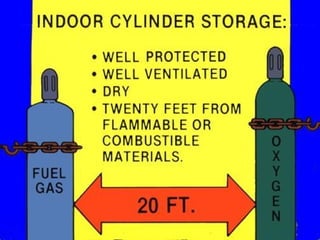

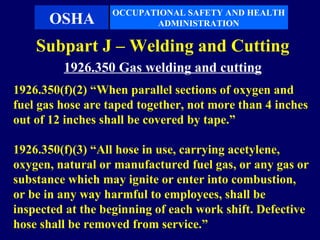

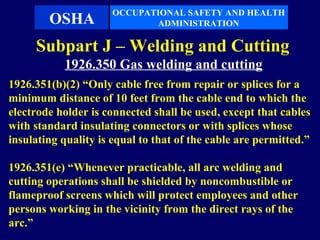

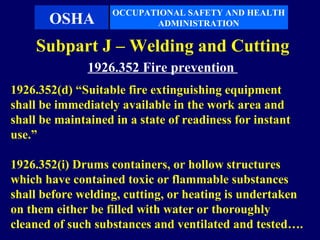

This document from OSHA outlines safety regulations for gas welding and cutting. It states that compressed gas cylinders must have valves secured and be secured upright during transport and storage. It also requires that oxygen and fuel gas hoses be inspected at the start of each shift and defective hoses removed from service. Welding and cutting operations must be shielded to protect employees from arc rays whenever possible. Suitable fire extinguishing equipment must also be immediately available in the work area.