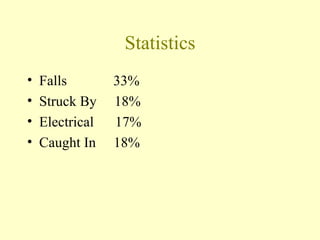

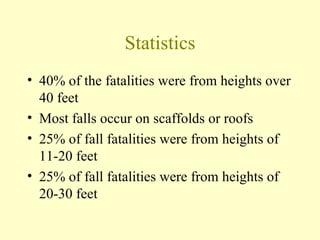

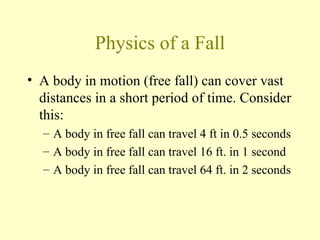

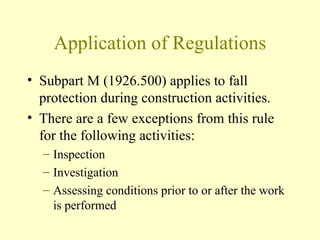

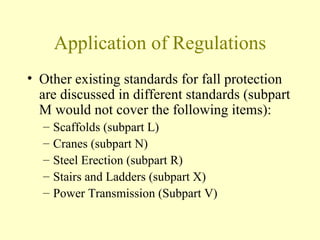

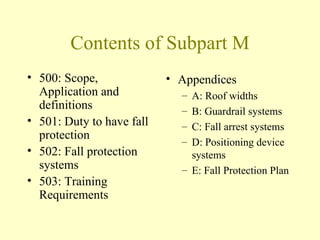

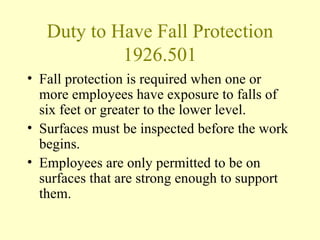

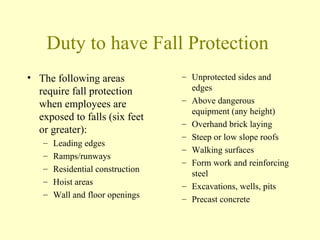

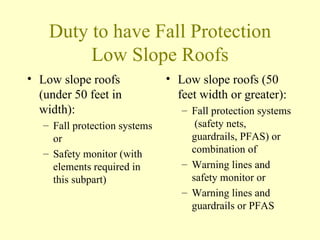

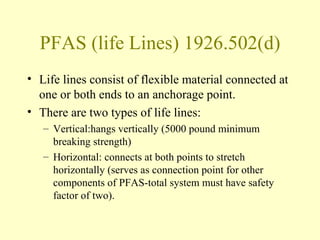

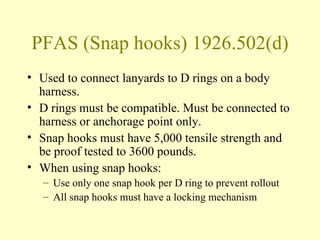

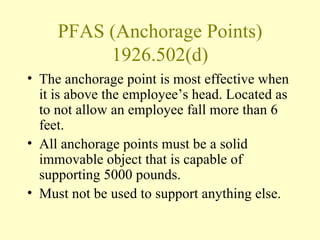

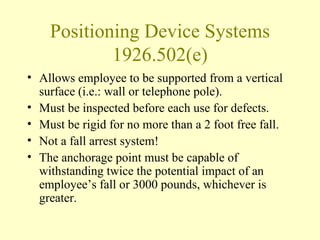

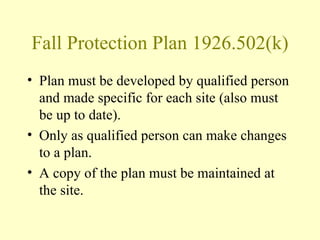

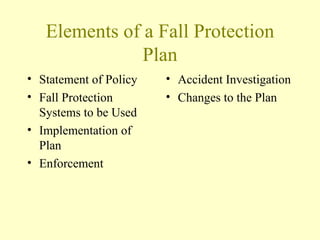

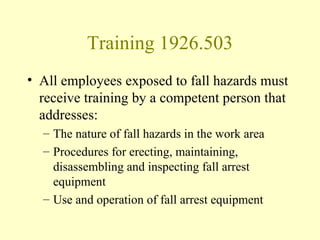

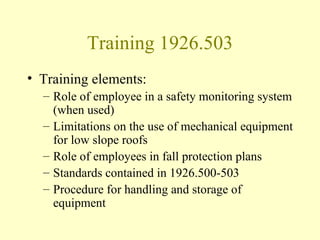

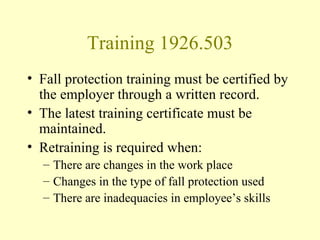

Falls from heights are a leading cause of fatalities in construction. The document outlines OSHA fall protection requirements, including the need for guardrails, harnesses, lanyards or other fall arrest systems for work 6 feet or more above a lower level. It also discusses training requirements and components of an effective fall protection plan.