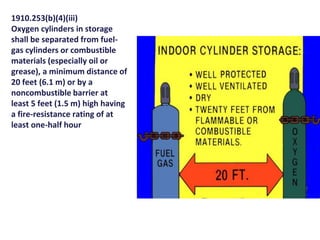

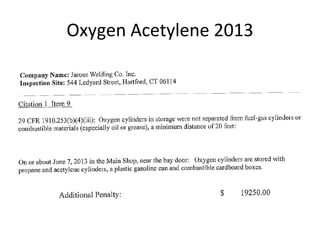

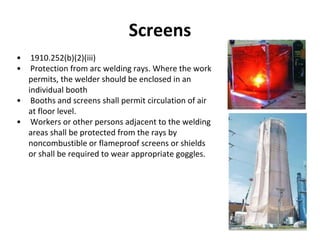

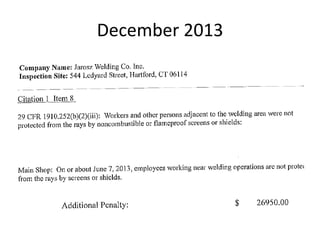

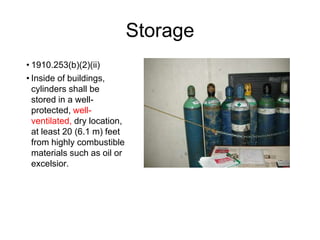

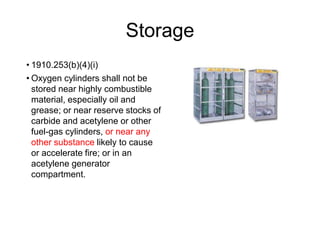

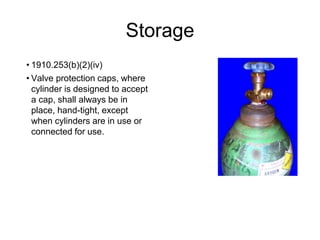

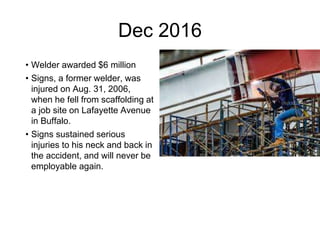

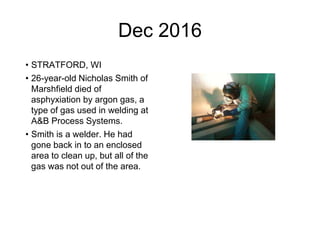

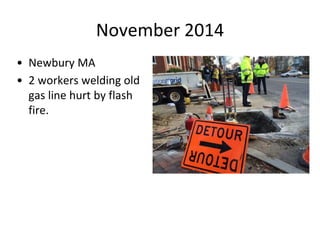

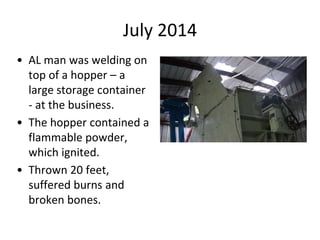

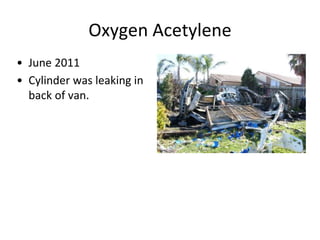

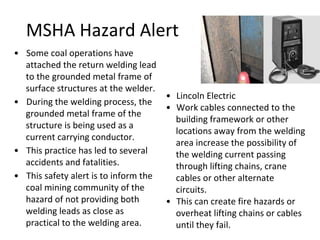

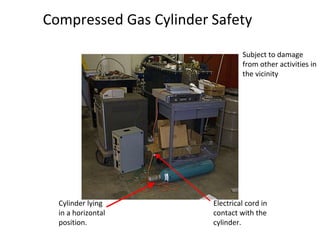

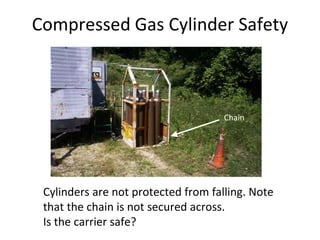

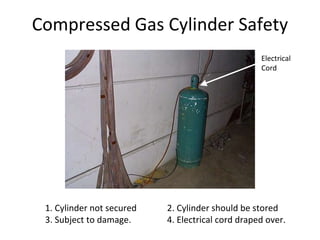

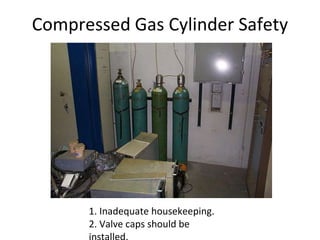

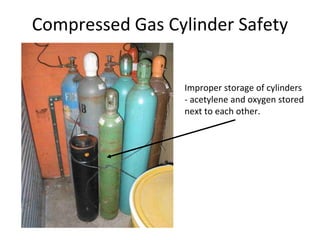

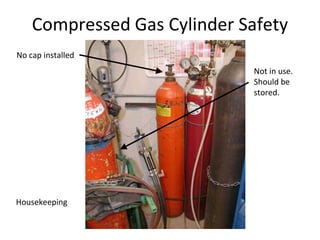

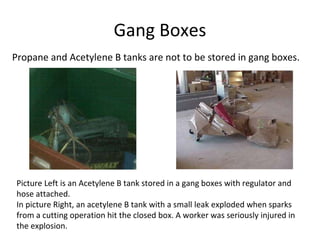

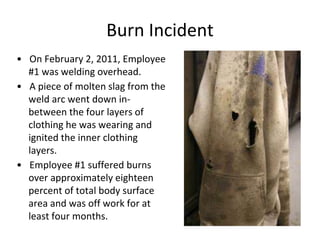

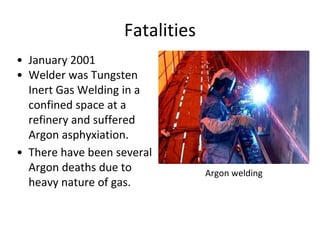

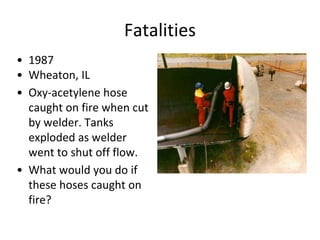

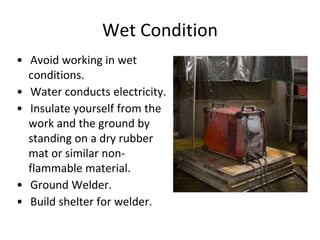

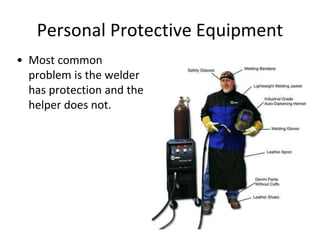

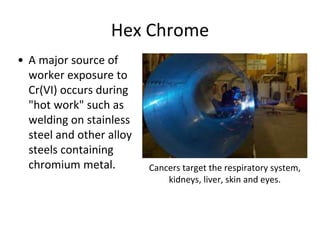

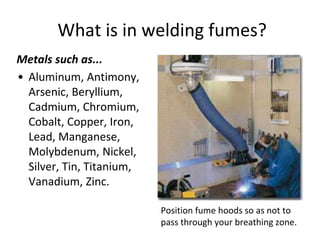

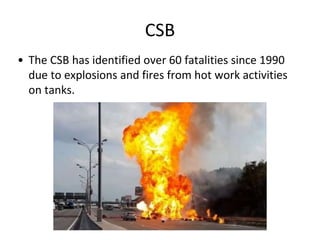

Welding safety regulations require proper storage of gas cylinders and protection from welding rays. Incident reports describe injuries from flash fires during gas line welding and argon asphyxiation in confined spaces. Guidelines state that oxygen and fuel gas cylinders should be separated by 20 feet or a fire-resistant barrier, and proper personal protective equipment is necessary for both welders and helpers. Hot work like welding can release toxic fumes and care must be taken in wet conditions or when welding coated metals.

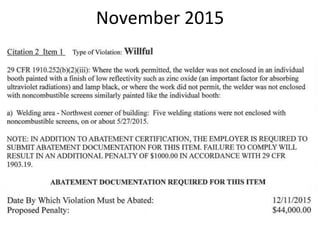

![25

27

33

68

95

253(b)(2)(iv)

253(b)(4)(i)

253(b)(2)(ii)

252(b)(2)(iii)

253(b)(4)(iii)

Welding, Cutting, & Brazing

[1910.251 – .255]

2

GAS WELDING & CUTTING – STORED AWAY FROM FUEL-GAS CYLINDERS

GENERAL REQUIREMENTS – PROTECTION FROM ARC WELDING RAY

GAS WELDING & CUTTING – CYLINDER STORAGE INSIDE BUILDINGS

SUBPARTQ

GAS WELDING & CUTTING – STORAGE NEXT TO COMBUSTIBLES

GAS WELDING & CUTTING – CYLINDER VALVE CLOSURE](https://image.slidesharecdn.com/welding2018511-180903160809/85/Welding-2018-511-2-320.jpg)