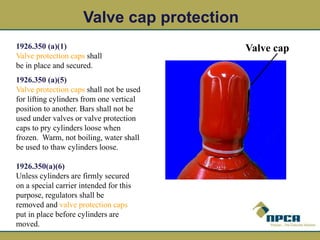

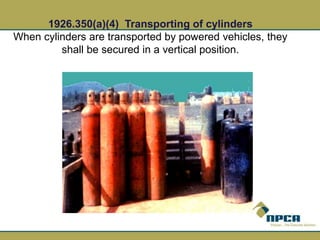

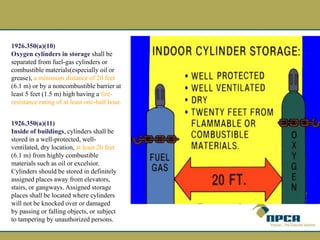

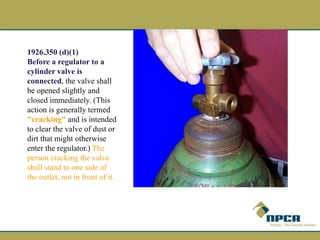

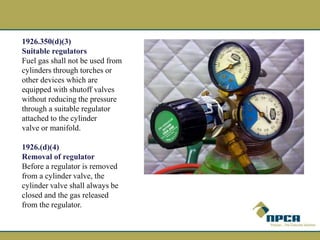

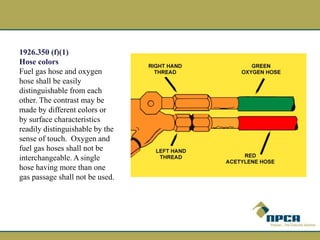

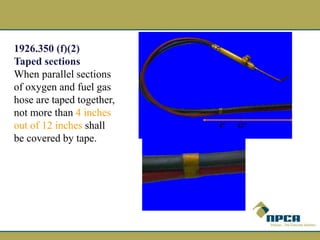

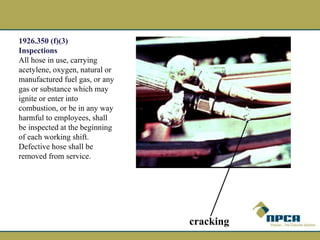

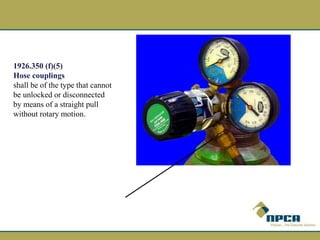

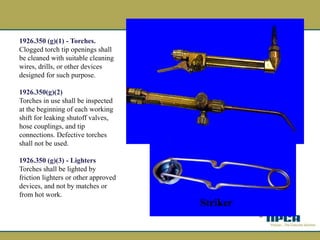

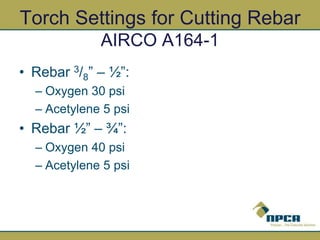

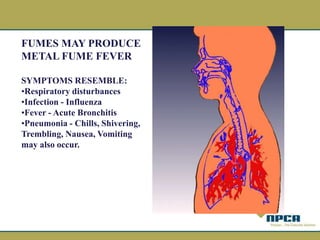

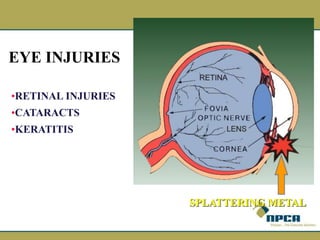

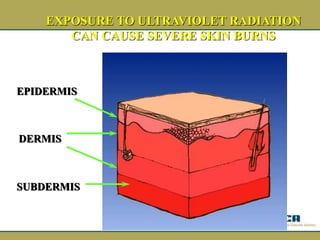

This document outlines safety regulations and requirements for welding and cutting as per OSHA Subpart J, including guidelines for the handling and storage of gas cylinders, inspection protocols for hoses and torches, as well as risks associated with exposure to fumes and noise. Specific procedures for securing cylinders, managing gas pressures, and preventing fire hazards are detailed. The document emphasizes the importance of proper safety measures to protect workers from physical injuries and health hazards related to welding activities.