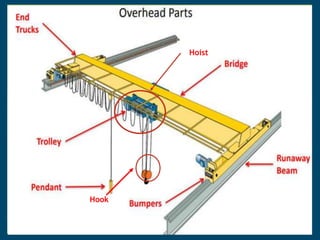

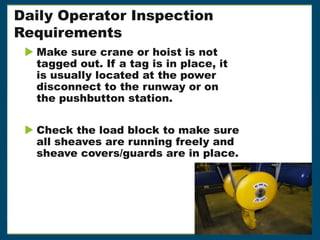

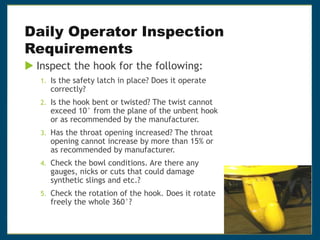

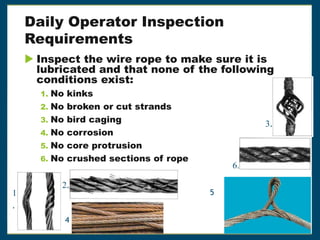

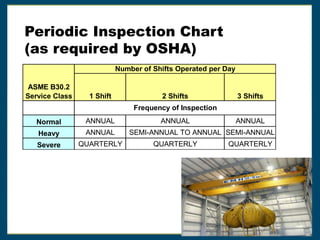

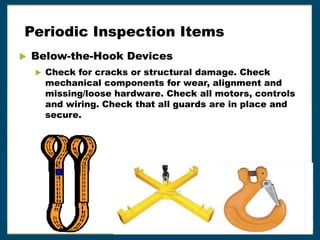

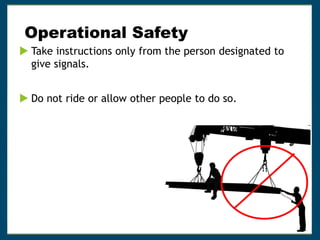

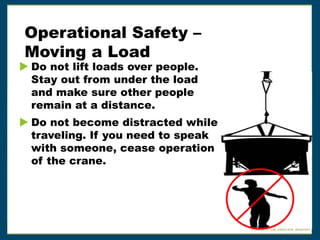

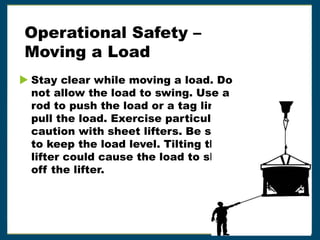

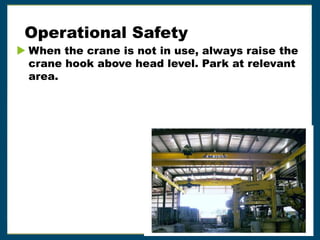

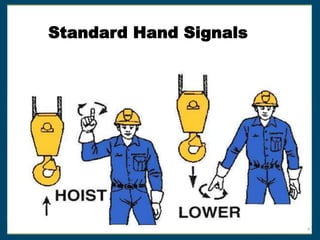

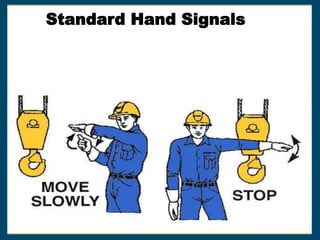

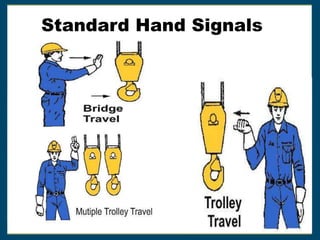

This document provides guidance on overhead crane safety. It outlines requirements for daily operator inspections, including checking the hook, wire rope, control devices and runway systems. Periodic inspections by a qualified person are also required, with frequencies ranging from quarterly to annually depending on crane use. Operational safety procedures are reviewed, such as following signal instructions, maintaining clear views, and not overloading. Recommended forms include a maintenance log, checklists, and training questionnaires. Standard hand signals for crane operations are also presented.