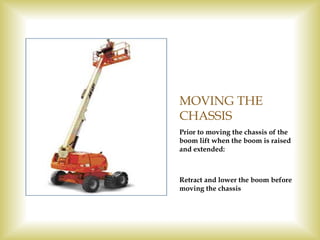

The document provides guidance on safely operating boom lifts. It outlines various OSHA requirements including fall protection, preoperational inspections of the lift, controls and their functions, safety hazards like pinch points and tip over risks. Operators must follow procedures like lowering and retracting the boom before driving, maintaining distance from power lines, and having a fire extinguisher. Practical training with an instructor is required before operating a boom lift independently.