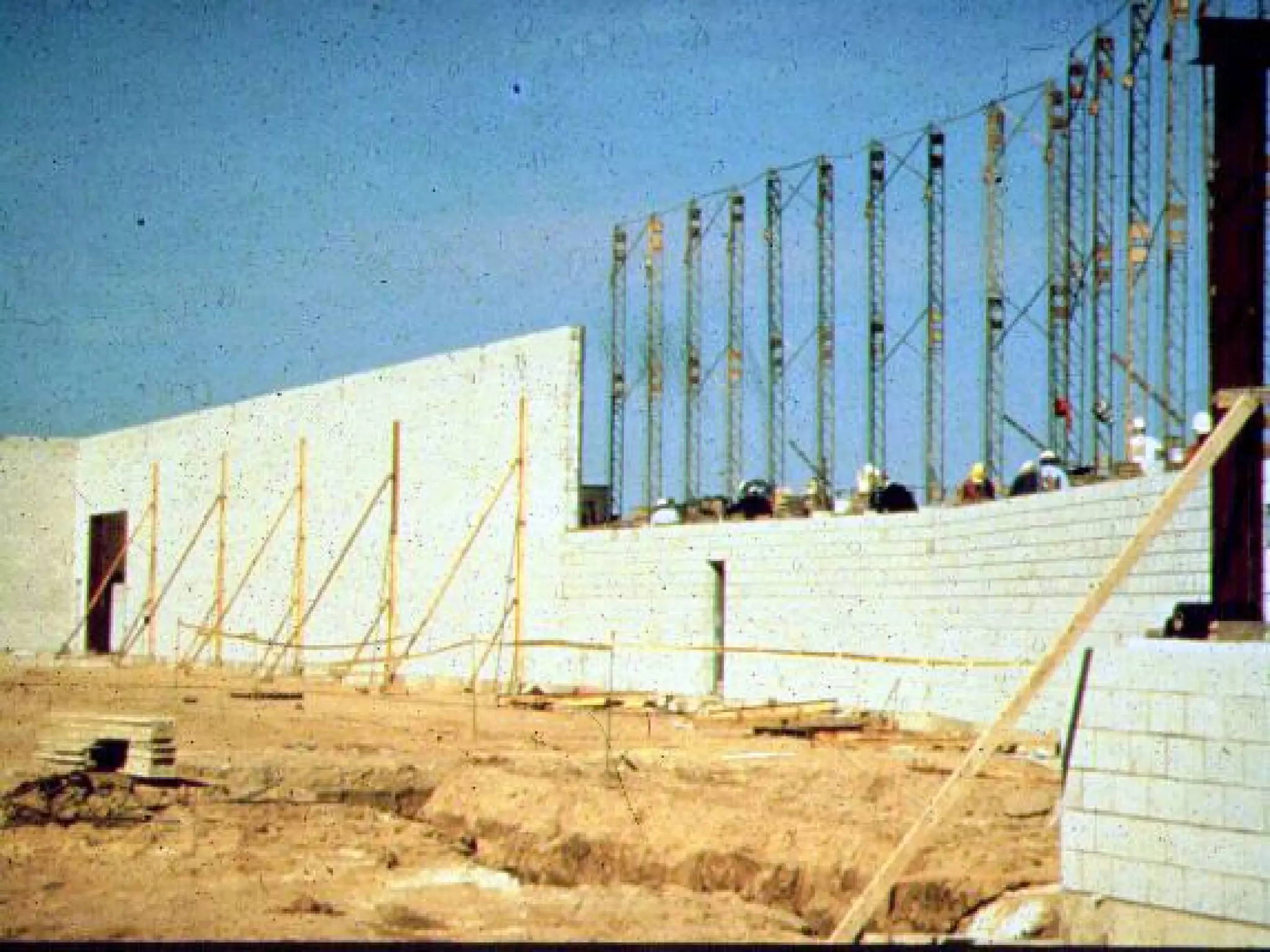

The document outlines Occupational Safety and Health Administration (OSHA) regulations regarding concrete and masonry construction. It addresses requirements for construction loads on concrete structures, guarding protruding reinforcing steel, prohibiting riding in concrete buckets, equipment and tool requirements including for bulk cement storage, bull floats, masonry saws, and lockout/tagout procedures, requirements for cast-in-place construction including shoring and reshoring, and requirements for masonry construction including establishing limited access zones and bracing walls over eight feet tall.