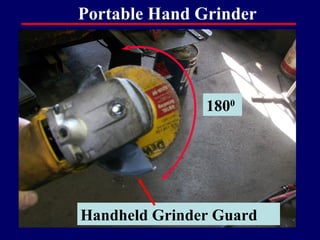

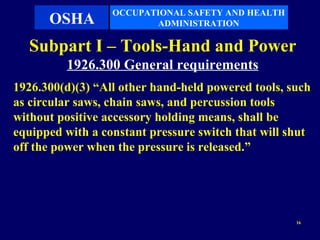

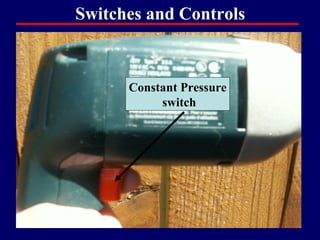

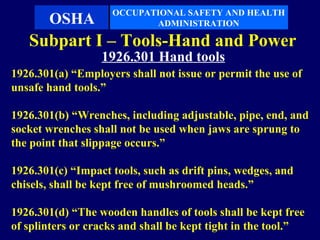

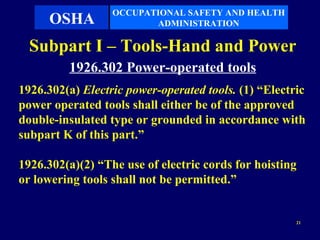

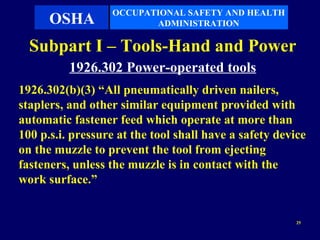

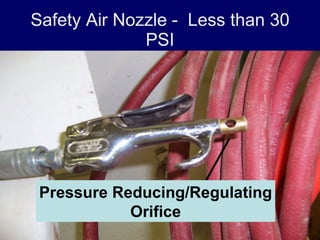

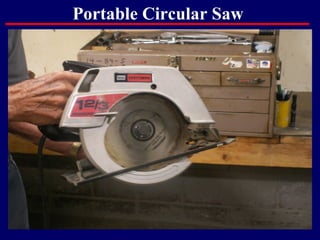

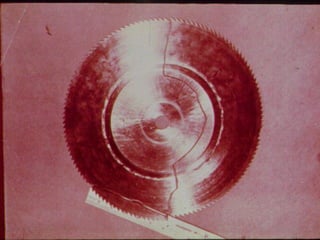

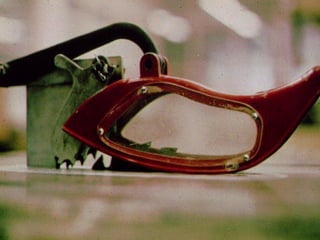

The document outlines Occupational Safety and Health Administration (OSHA) regulations for hand and power tools. It discusses requirements for maintaining tools in safe condition, guarding power tools, and types of machine guarding. Regulations address safety features for switches on handheld power tools and proper use and maintenance of abrasive wheels, woodworking machines, jack systems, and mechanical power transmission devices.