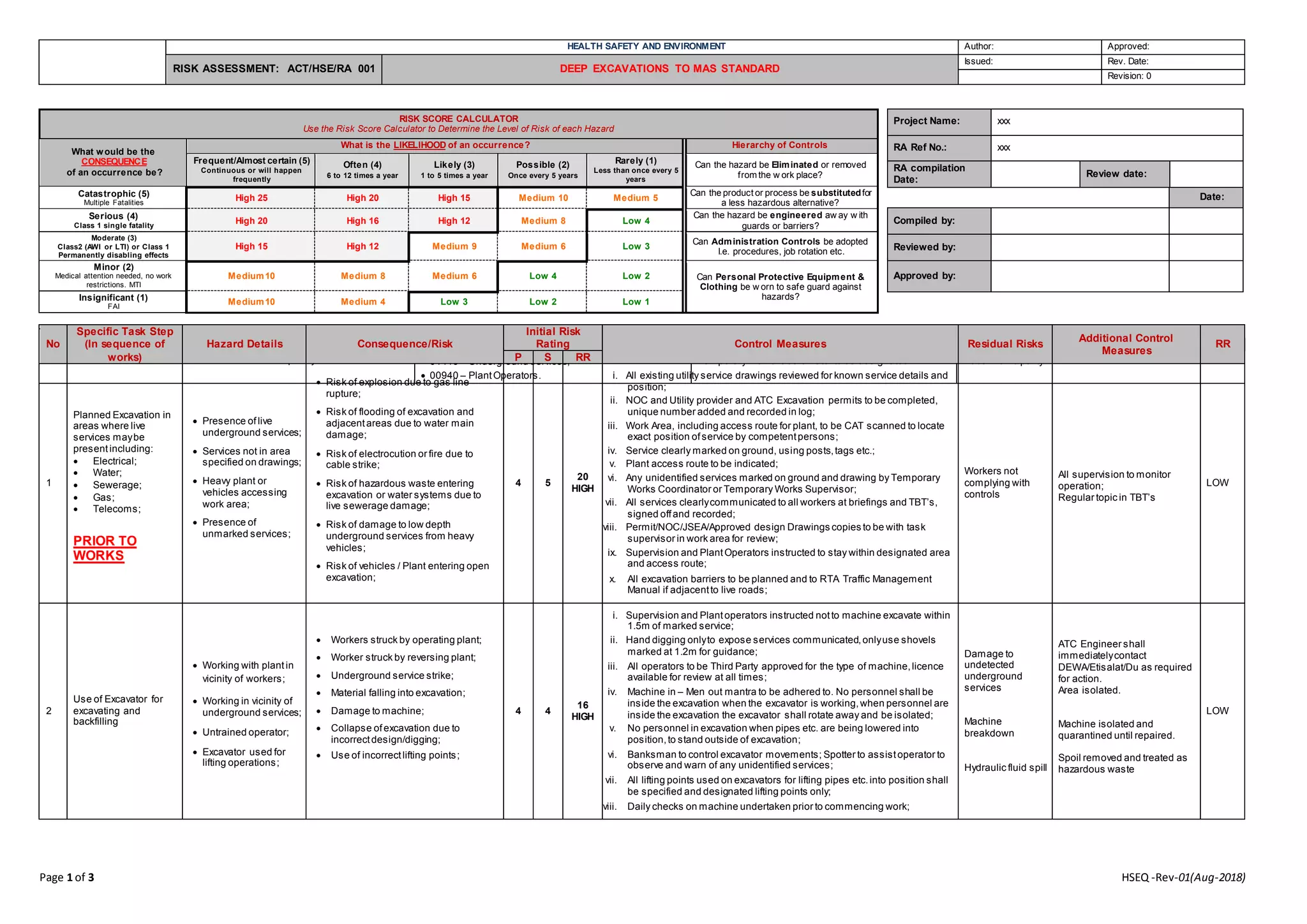

This document outlines a risk assessment for deep excavations, detailing potential hazards, their consequences, and control measures to mitigate risks associated with excavation work. It includes a risk score calculator to evaluate the likelihood and severity of hazards, emphasizing the importance of safety protocols and worker training. The document also specifies requirements for permits, inspections, and emergency procedures to ensure worker safety during excavation activities.