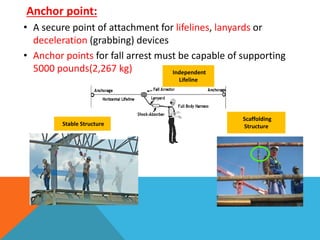

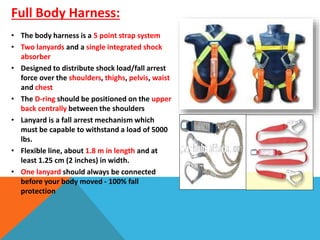

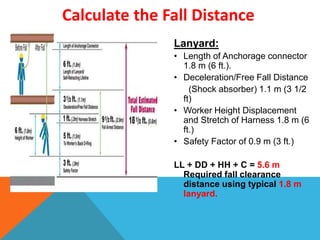

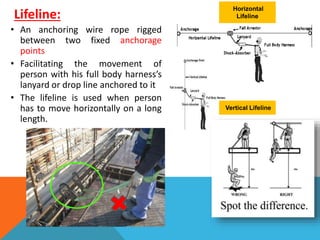

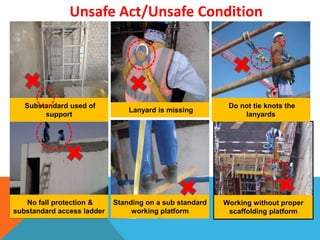

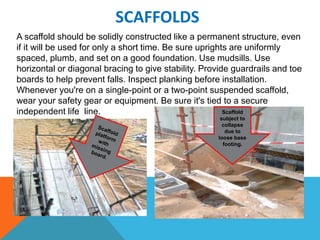

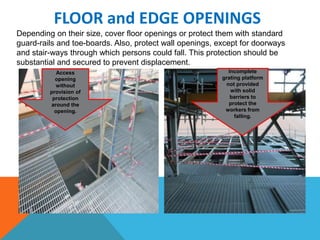

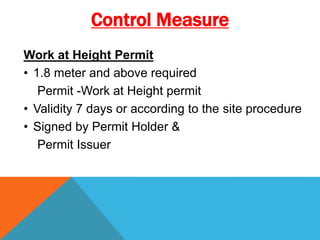

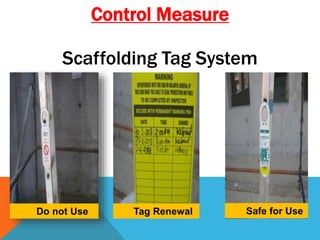

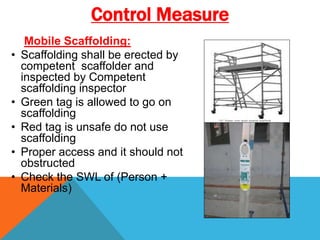

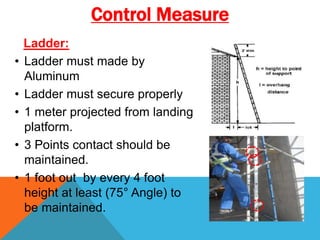

This document discusses work at height safety. It defines work at height as any work performed more than 6 feet above the ground. It provides examples of work at height including construction, maintenance, and scaffolding work. The document outlines several fall hazards and control measures that should be implemented when working at height, such as using fall protection equipment like harnesses and lifelines, installing guardrails and covers over floor openings, following permitting procedures, and providing fall protection training to workers.