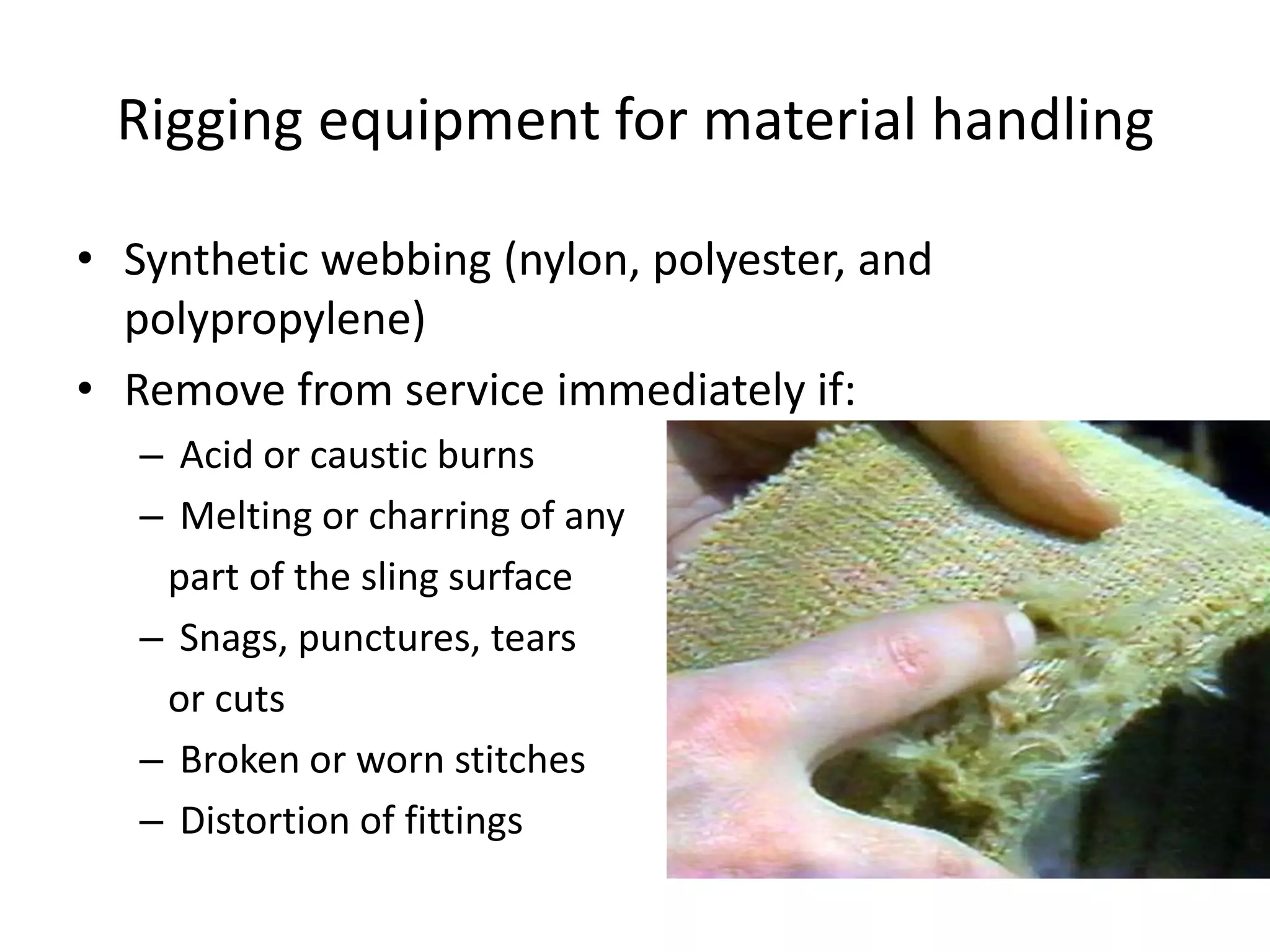

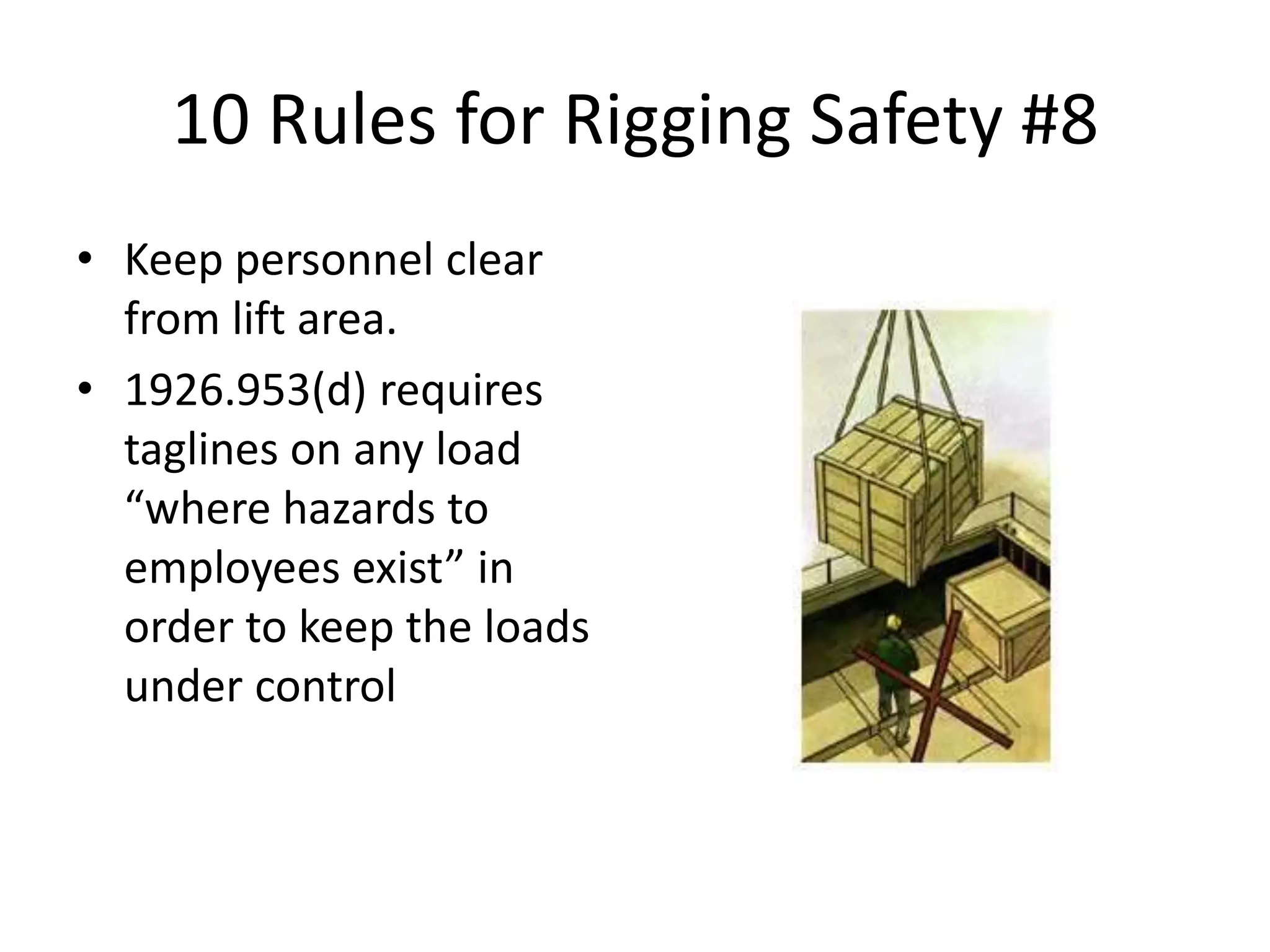

Three employees were injured in separate rigging accidents over a two month period. In the first incident, an employee was struck in the head by a metal pulley when the nylon sling it was attached to broke under tension. In the second incident, an employee was struck by a falling 2,000 pound concrete form that broke loose from its rigging during a crane lift. In the third incident, an employee was fatally struck on the head by a drilling pipe that came loose from its rigging during a lift. The document outlines 10 rules for rigging safety including knowing load weights, rigging capacities, center of gravity, sling angles, inspections, and using tag lines and signal persons.