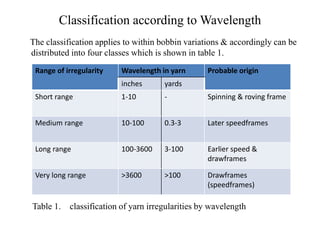

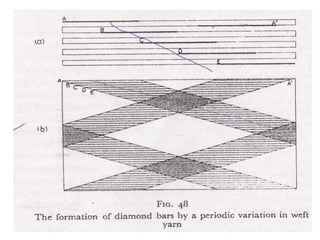

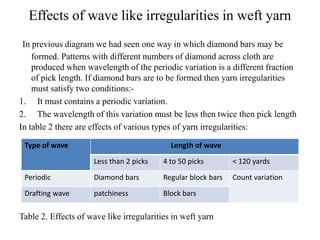

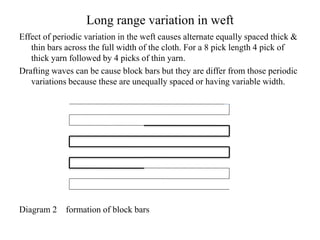

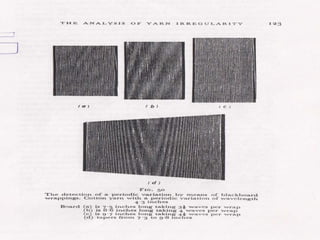

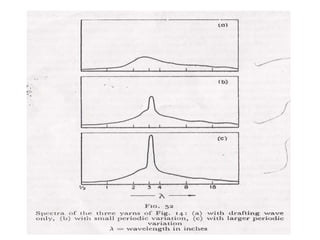

The document discusses yarn irregularities, their classification based on wavelength and type, and their effects on cloth appearance. It covers short, medium, and long range variations in weft yarn that can cause diamond barring, block bars, and count variations in cloth. Periodic variations are more likely to cause faults than drafting waves. Detection of small periodic variations can be done by winding yarn on a blackboard. Long range irregularities originating from earlier machines are measured using regularity testers equipped with electrical filters. The Uster Spectrograph automatically draws spectra of irregularities in fibers and yarns.