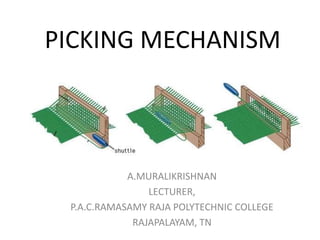

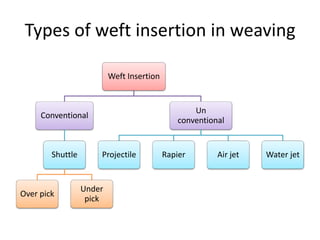

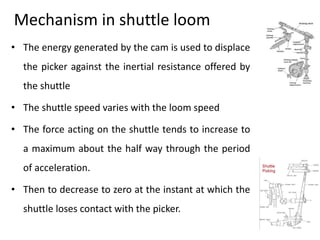

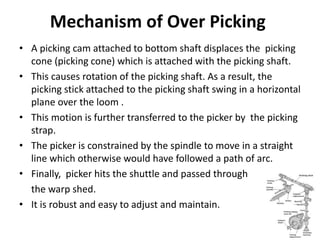

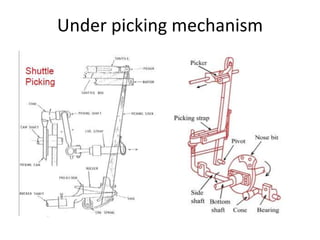

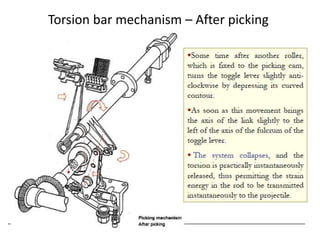

The document discusses the picking mechanism in weaving, which involves inserting weft yarn through warp yarns and outlines various types of weft insertion methods, including shuttle, projectile, and rapier mechanisms. It explains the dynamics of shuttle propulsion, power requirements, and the complexities involved in optimizing picking efficiency. Additionally, it details the differences between conventional and projectile picking methods, emphasizing energy storage and the acceleration characteristics of the picking elements.