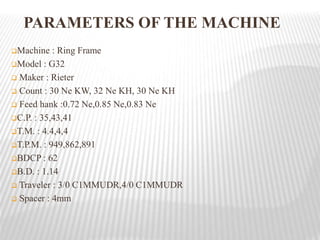

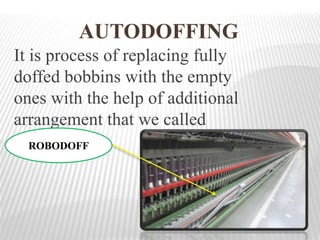

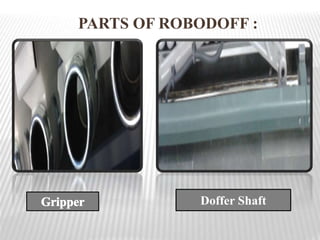

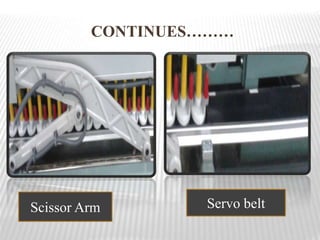

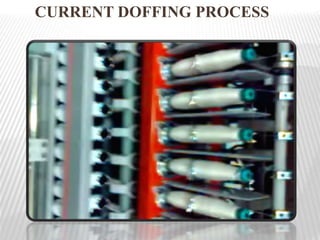

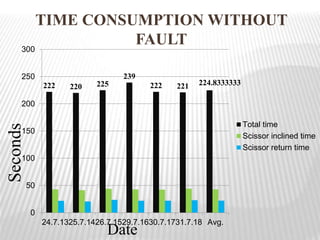

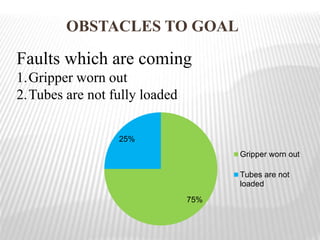

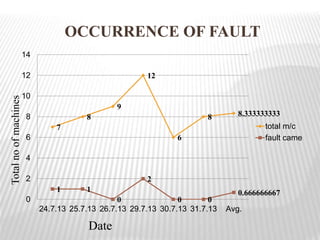

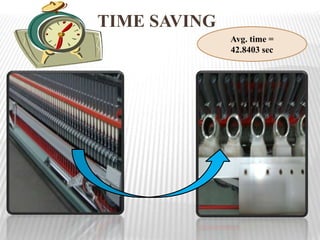

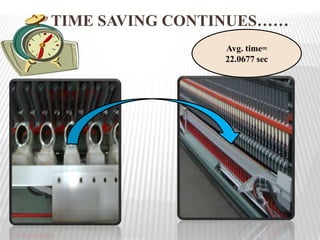

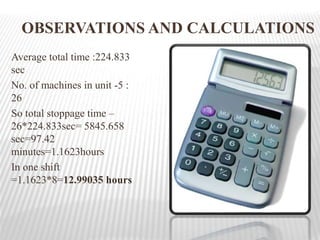

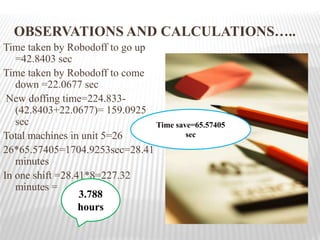

This document summarizes a student's industrial training project on autodoffing processes at a textile company. The student studied the autodoffing system of ring frame machines, which automatically replaces full bobbins with empty ones using a robot called a robodoff. The student collected data on manual versus automatic doffing times, identified issues like worn grippers that caused faults, and proposed solutions to reduce doffing time and increase production. Calculations showed the proposed autodoffing process could save over 3 hours of production time per shift across all machines.