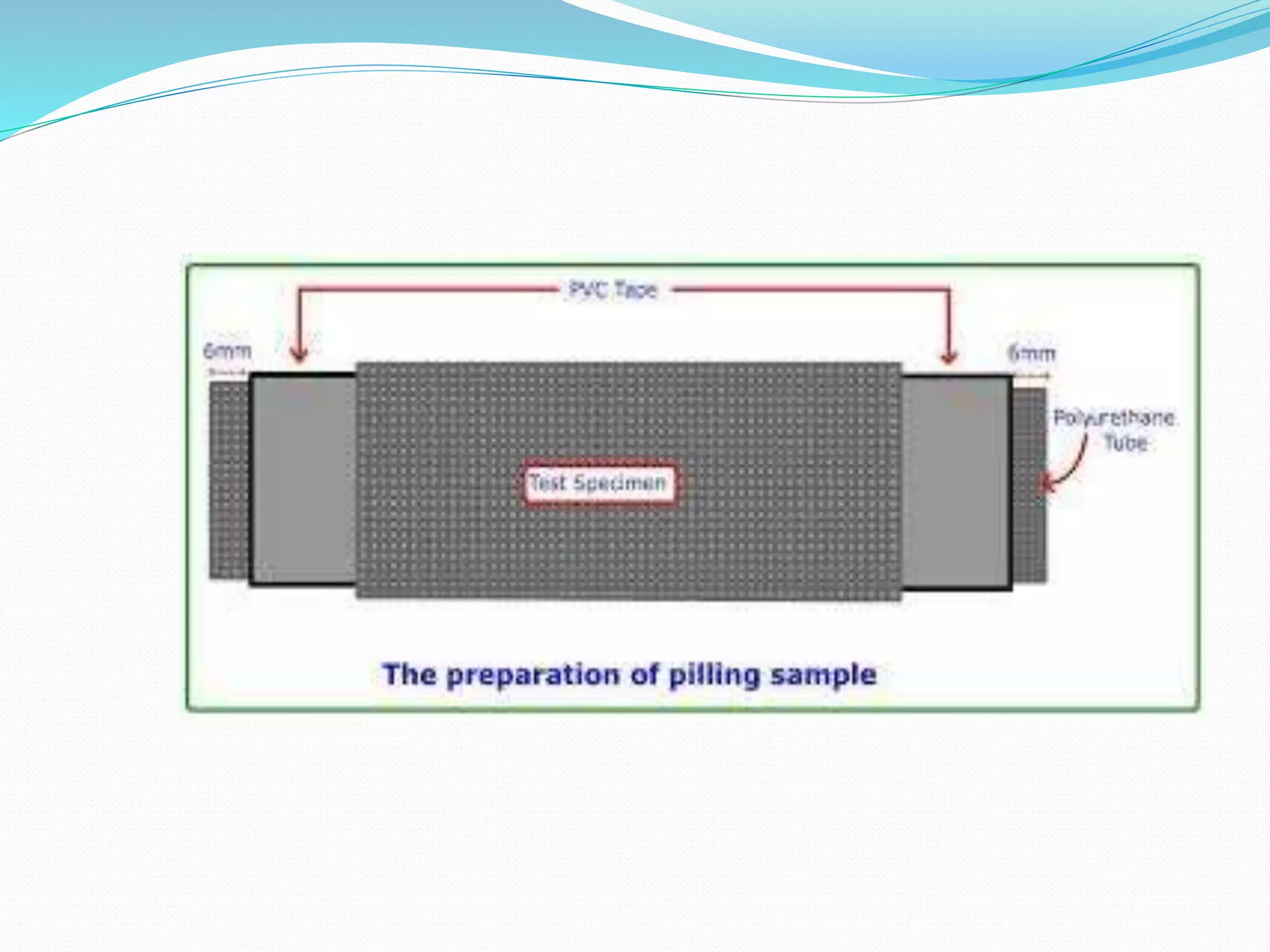

The document presents a comprehensive overview of fabric pilling, detailing its causes, prevention methods, and a pilling test protocol. Pilling occurs due to fiber abrasion and can be minimized through techniques like using high twisted yarn and special chemical treatments. A specific testing method involving fabric specimens and a cork-lined box is outlined to assess the extent of pilling through visual ratings.