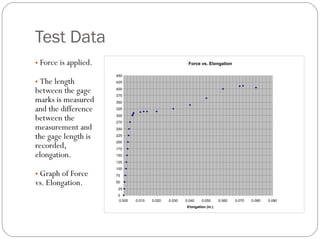

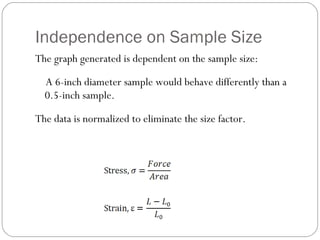

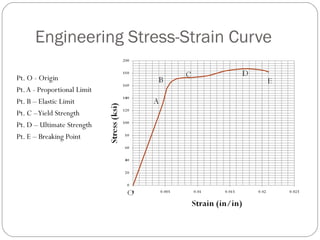

The document discusses how to determine the mechanical properties of a material from a stress-strain curve generated by a uniaxial tensile test. A cylindrical material sample is placed in a tensile testing machine and force is applied to elongate the sample while measuring changes in length. A graph of applied stress versus strain is generated and used to identify properties like proportional limit, elastic limit, yield strength, ultimate strength, and modulus of elasticity. The stress-strain curve also indicates whether a material is brittle or ductile based on its percent elongation. Mechanical properties determined from this process guide material selection based on strength, stiffness, and ductility requirements.