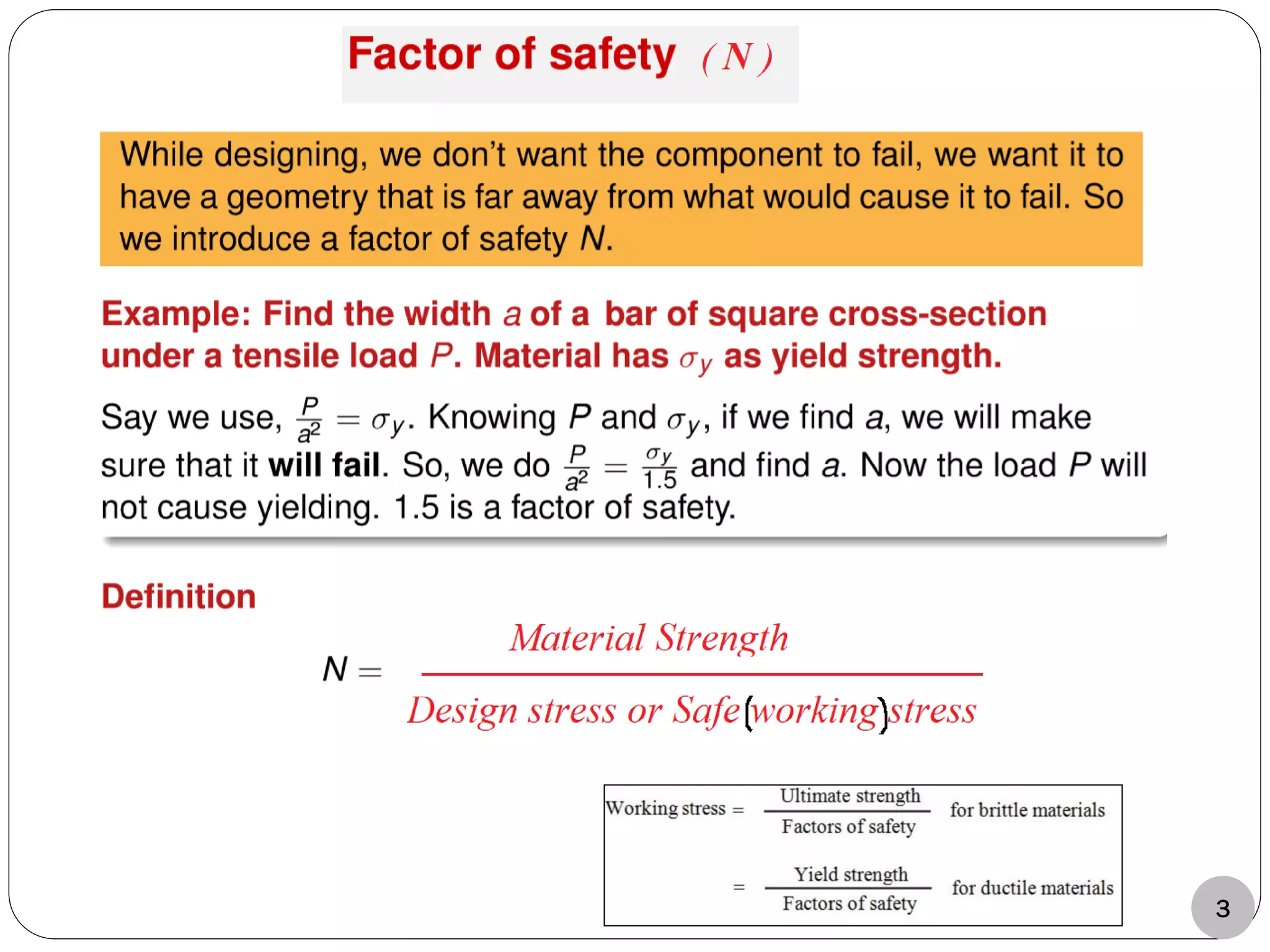

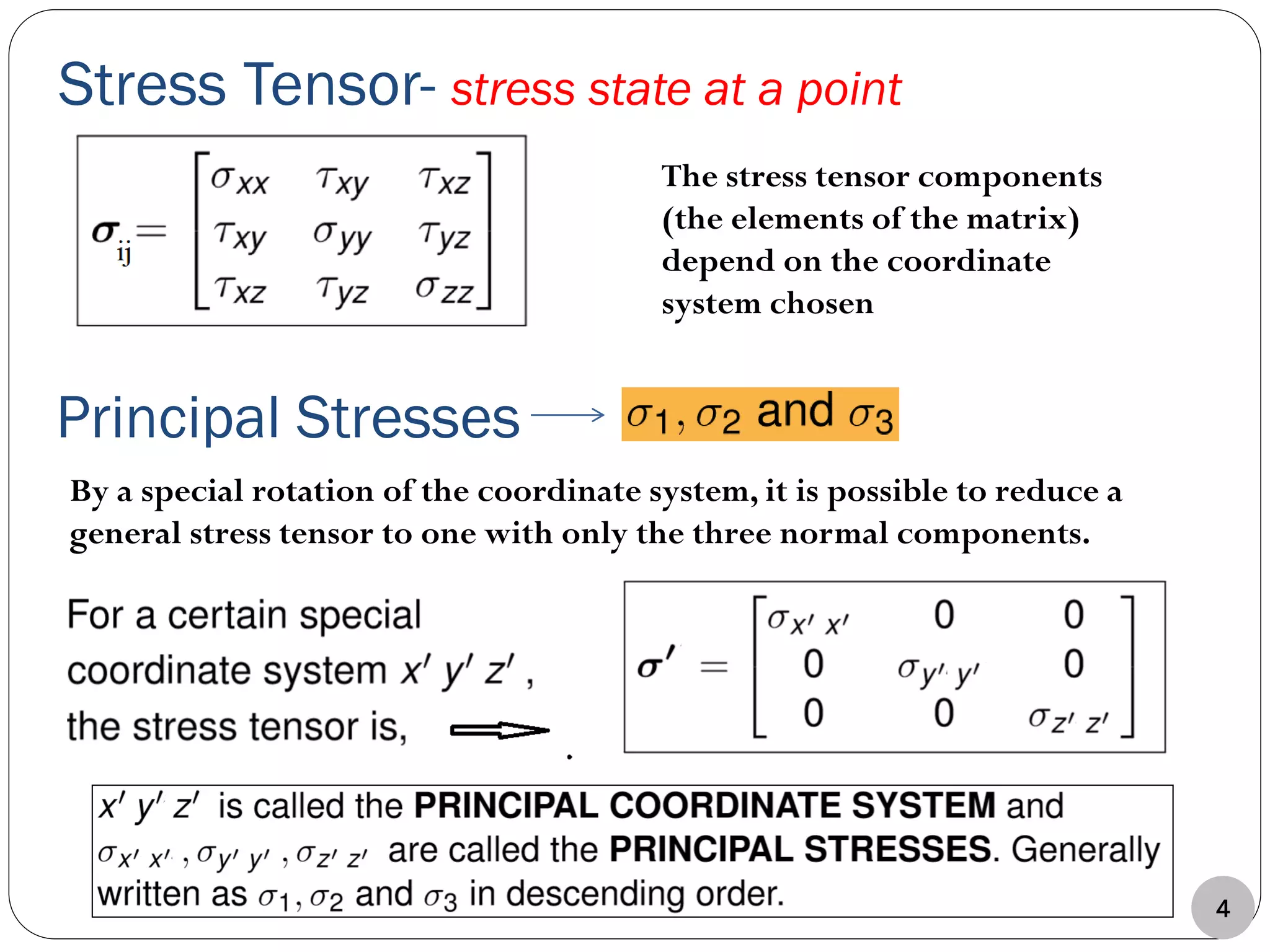

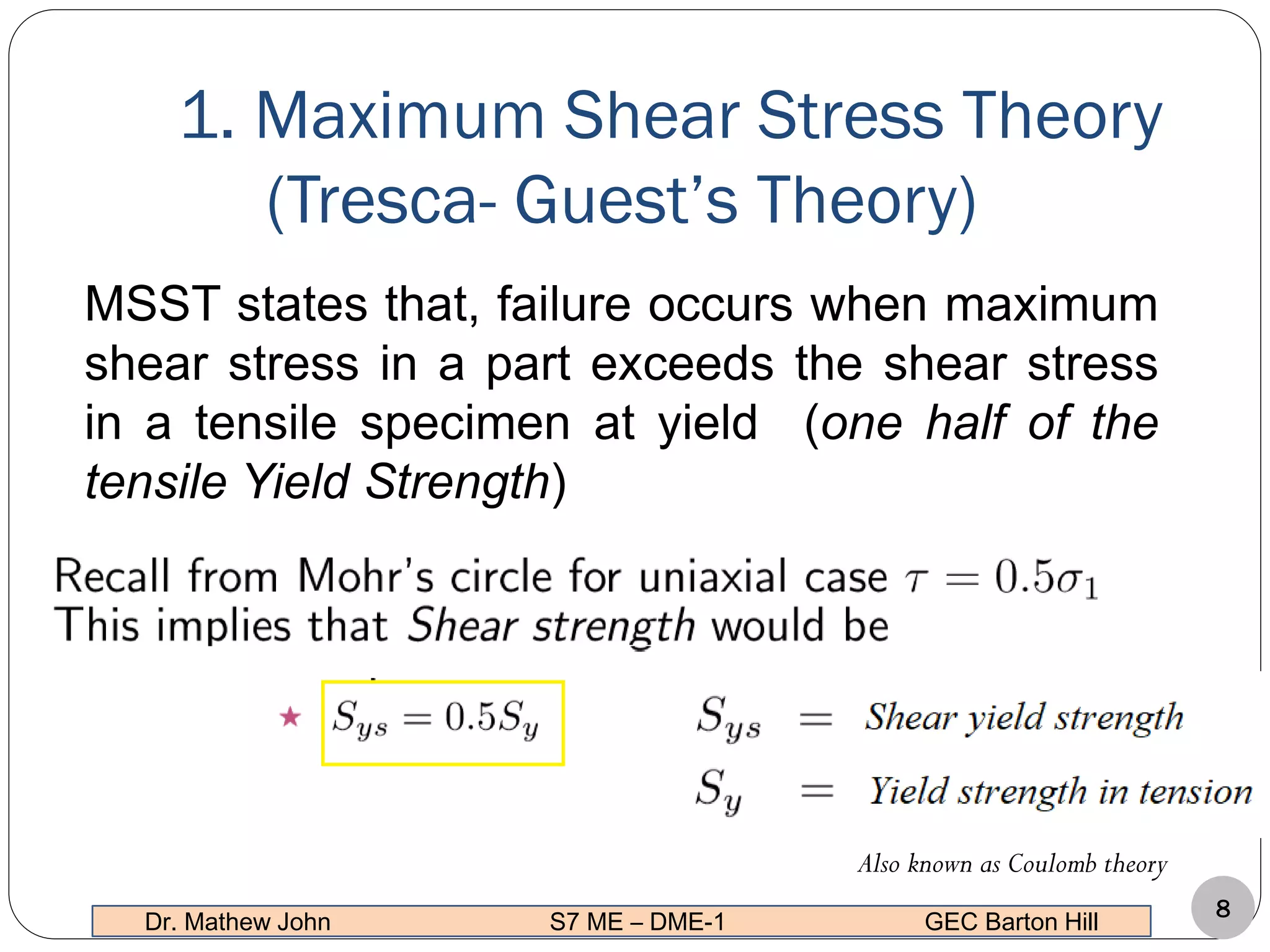

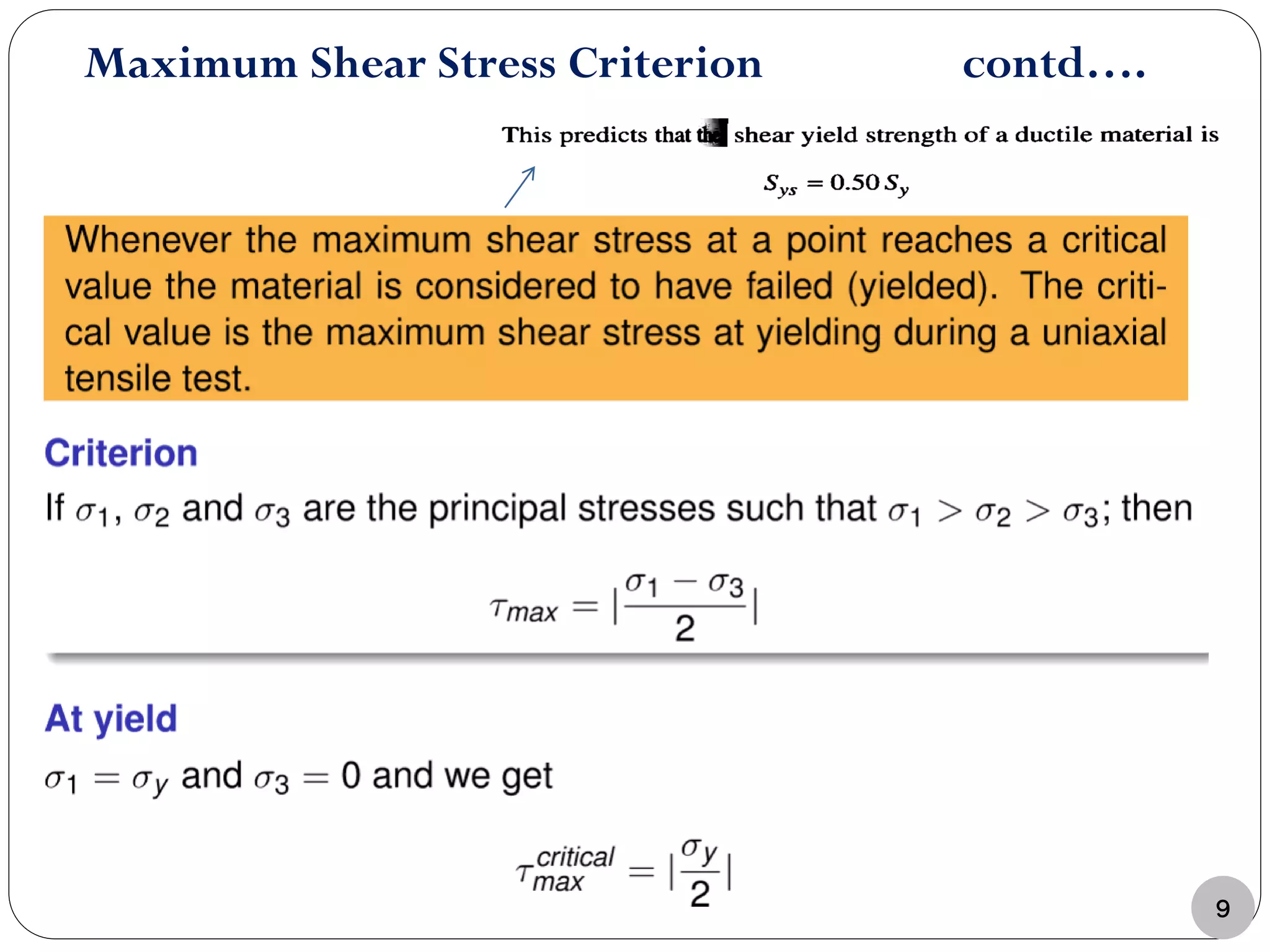

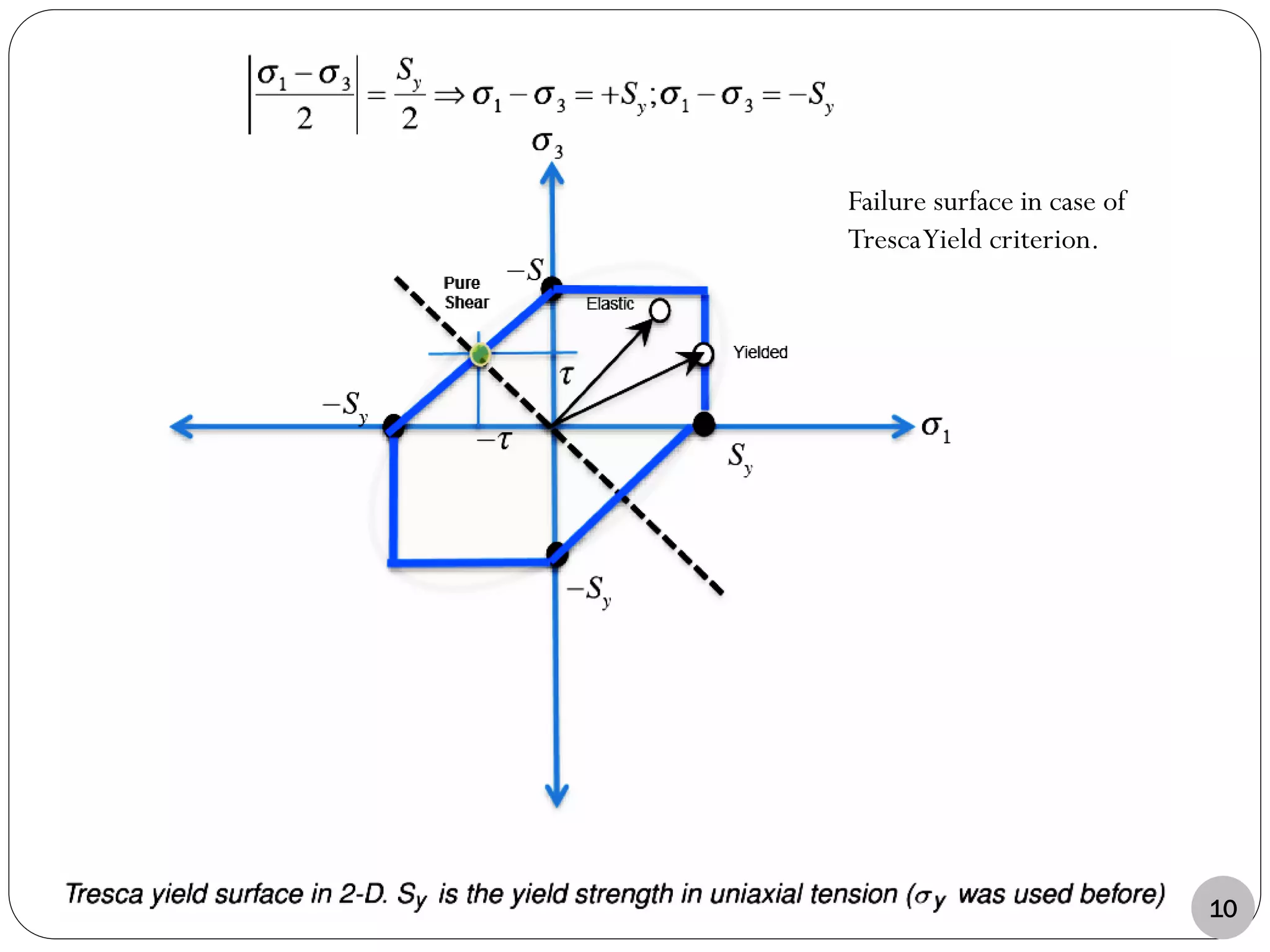

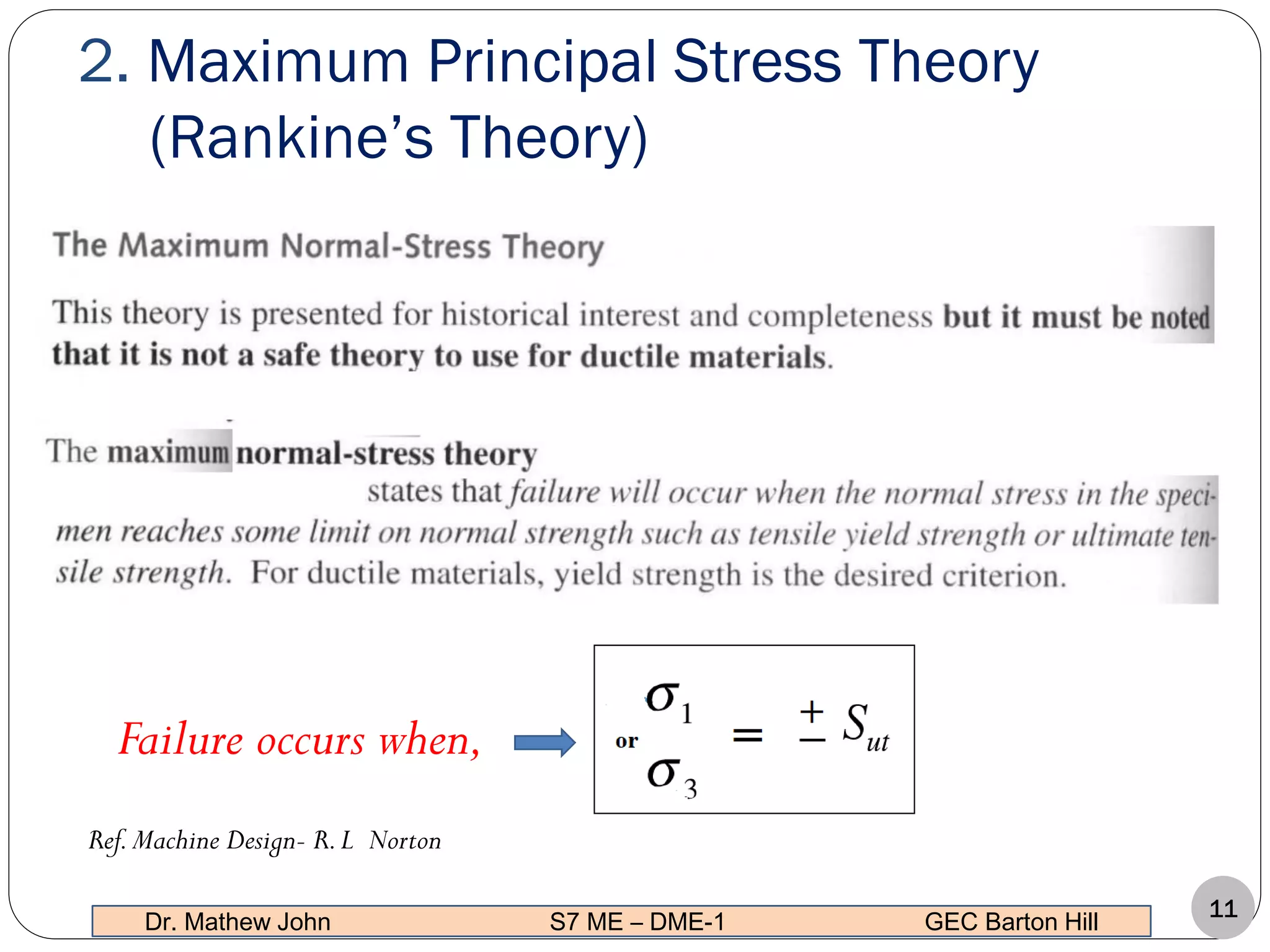

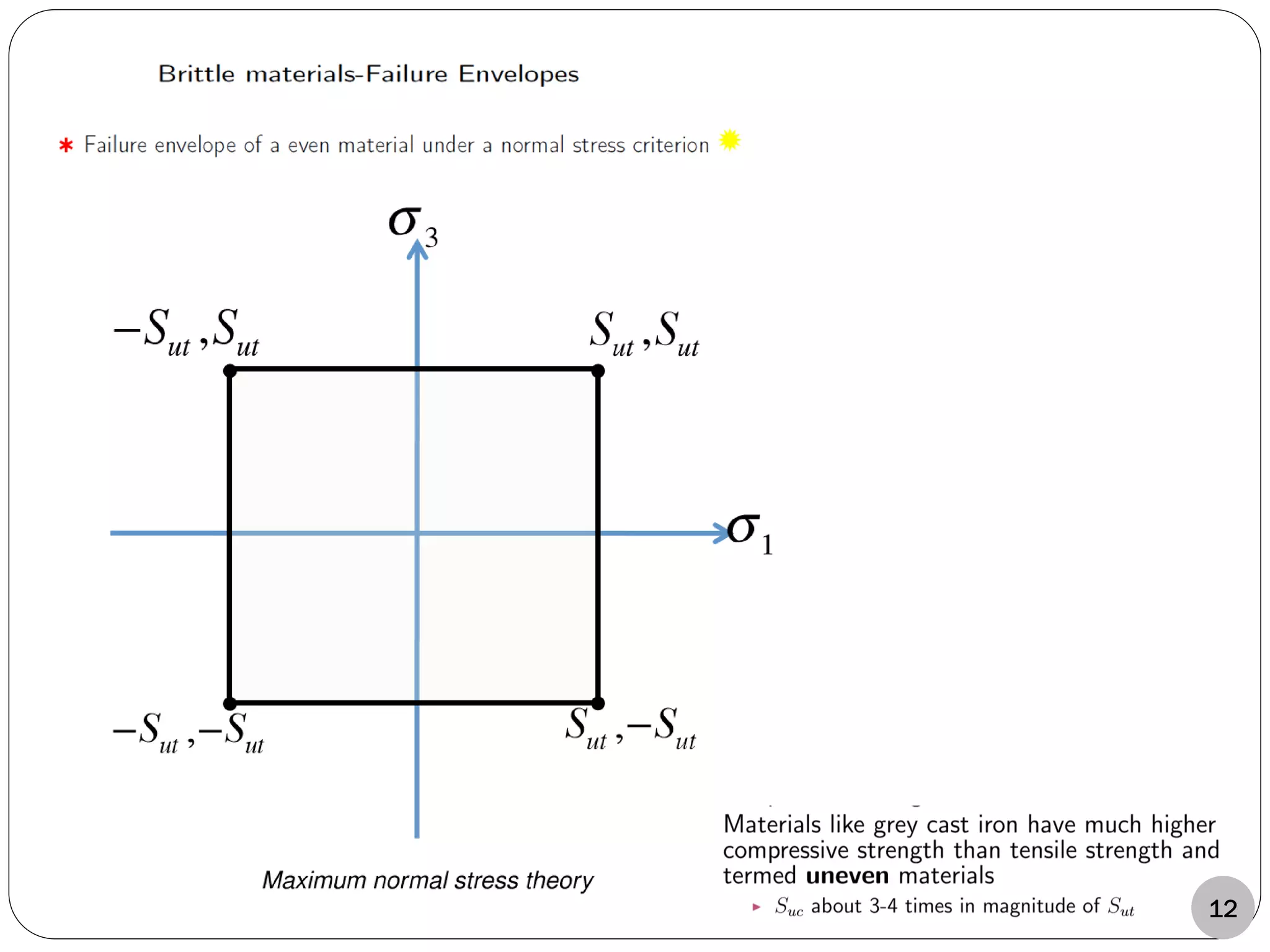

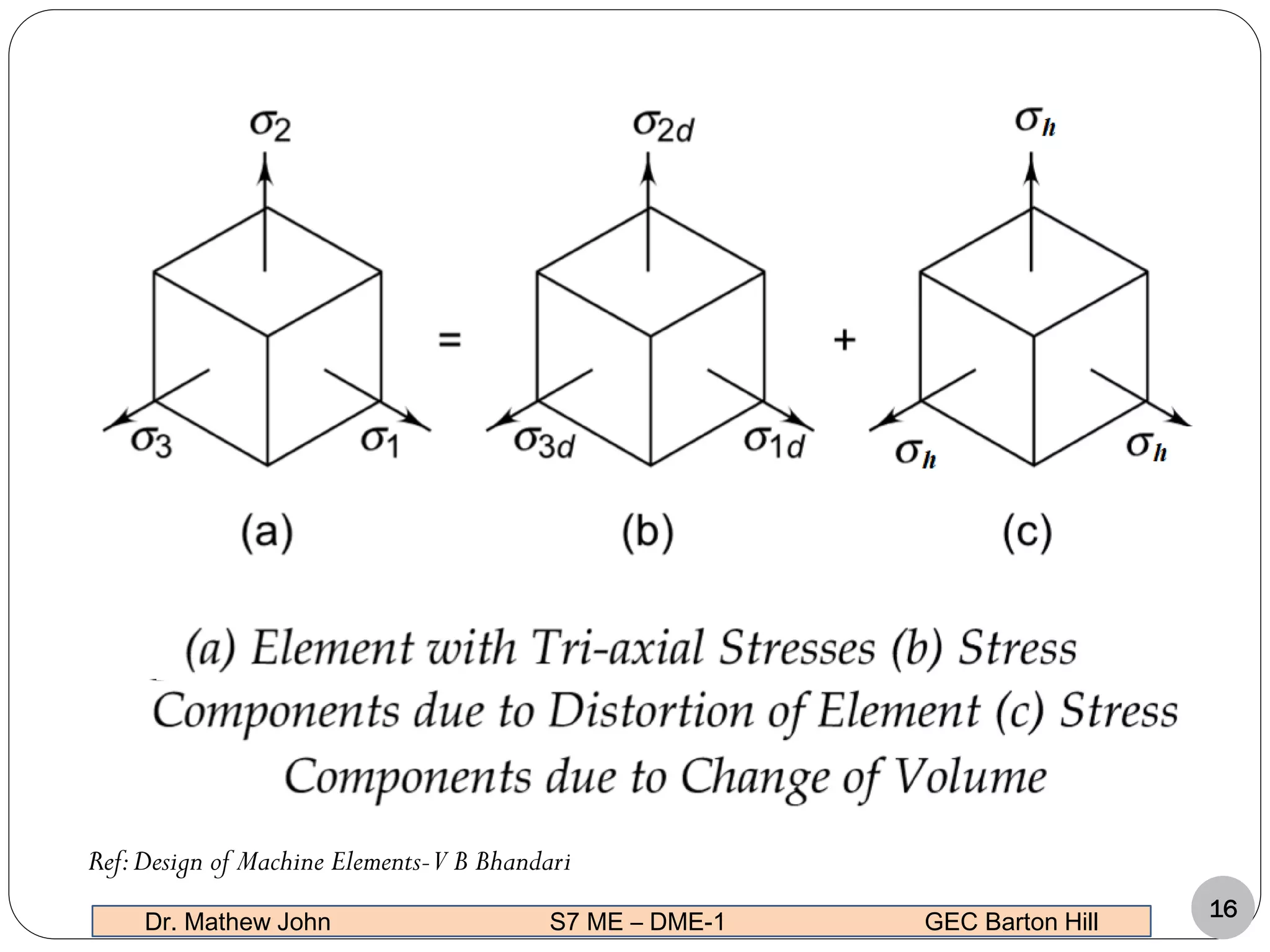

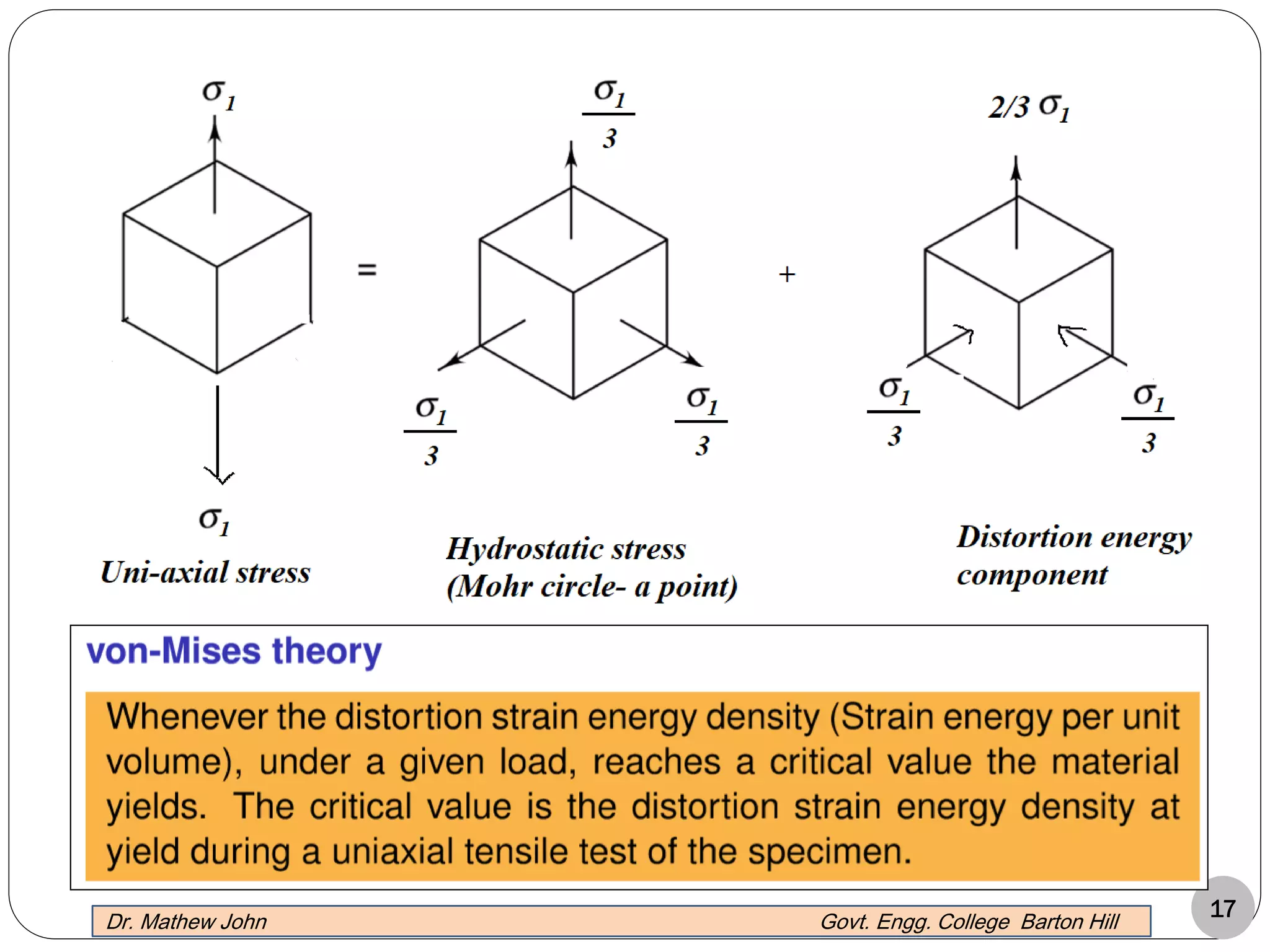

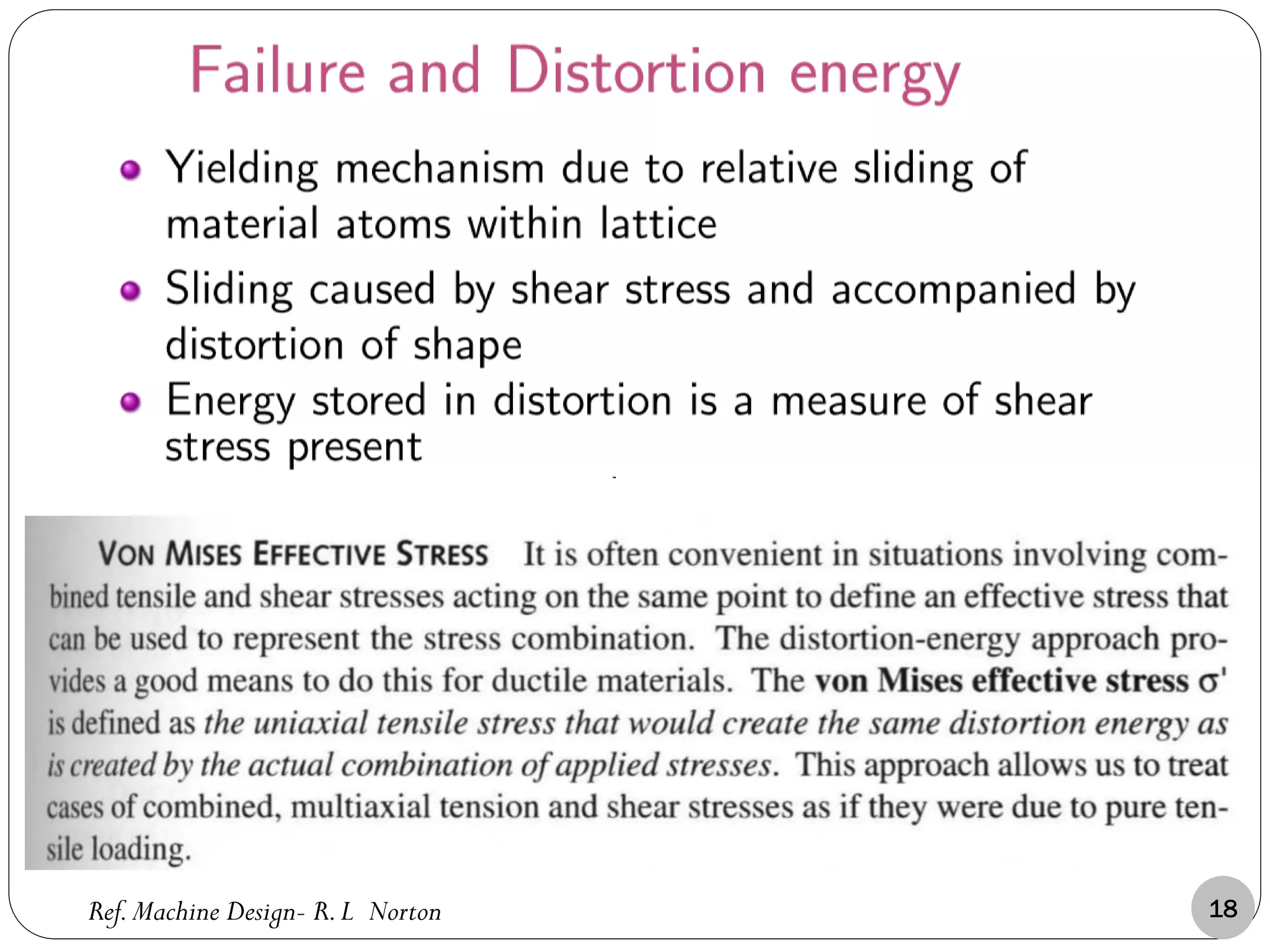

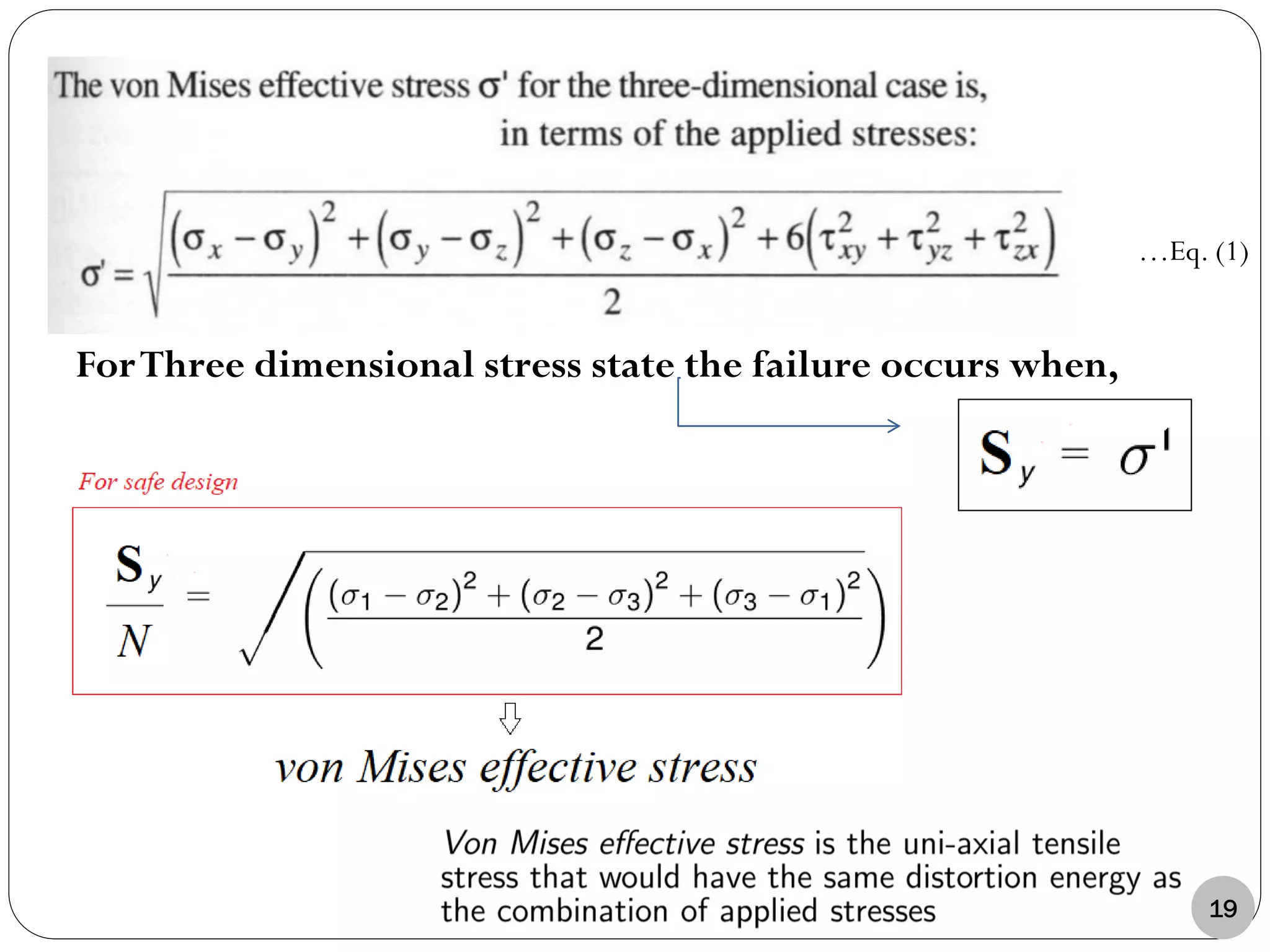

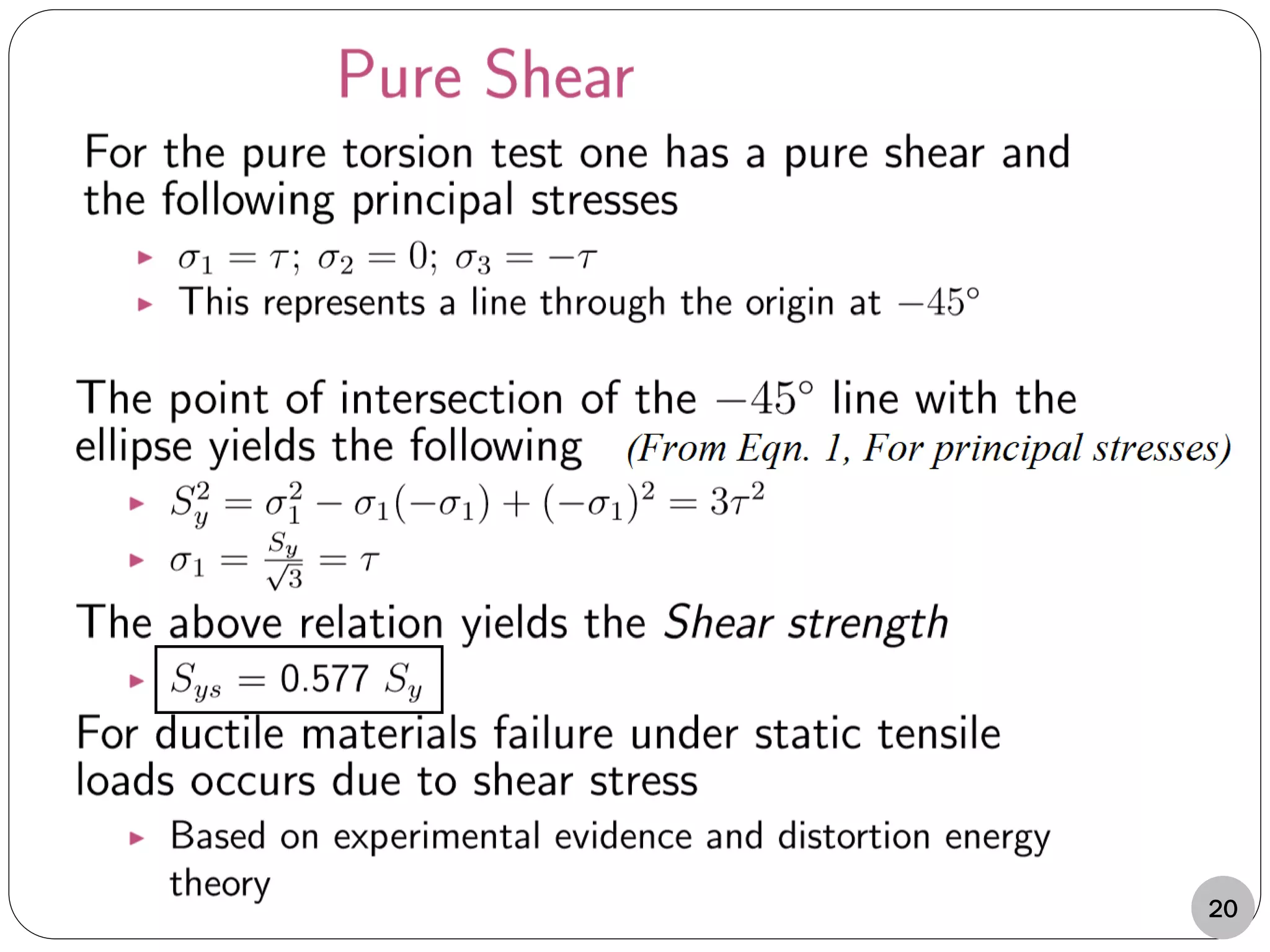

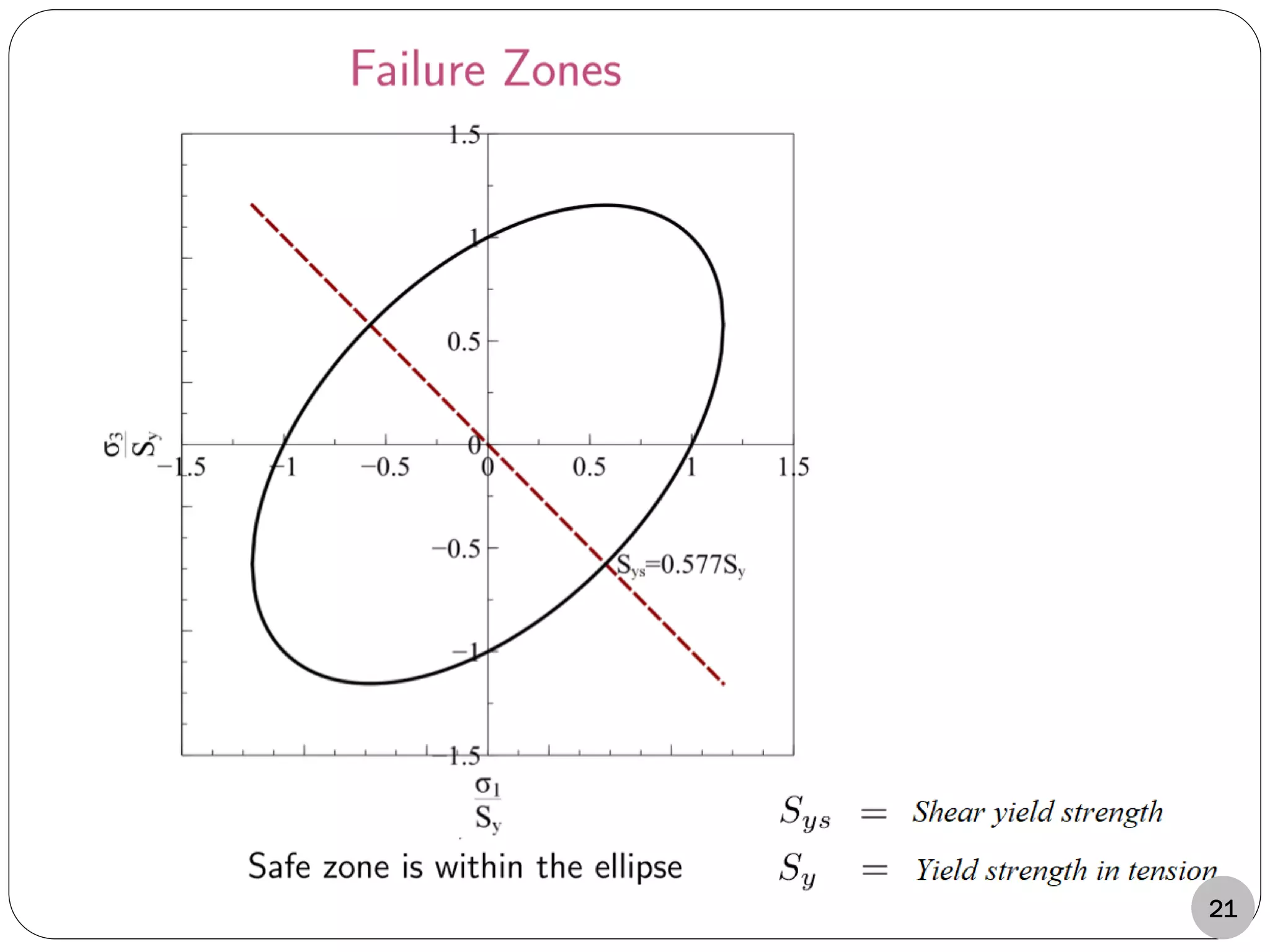

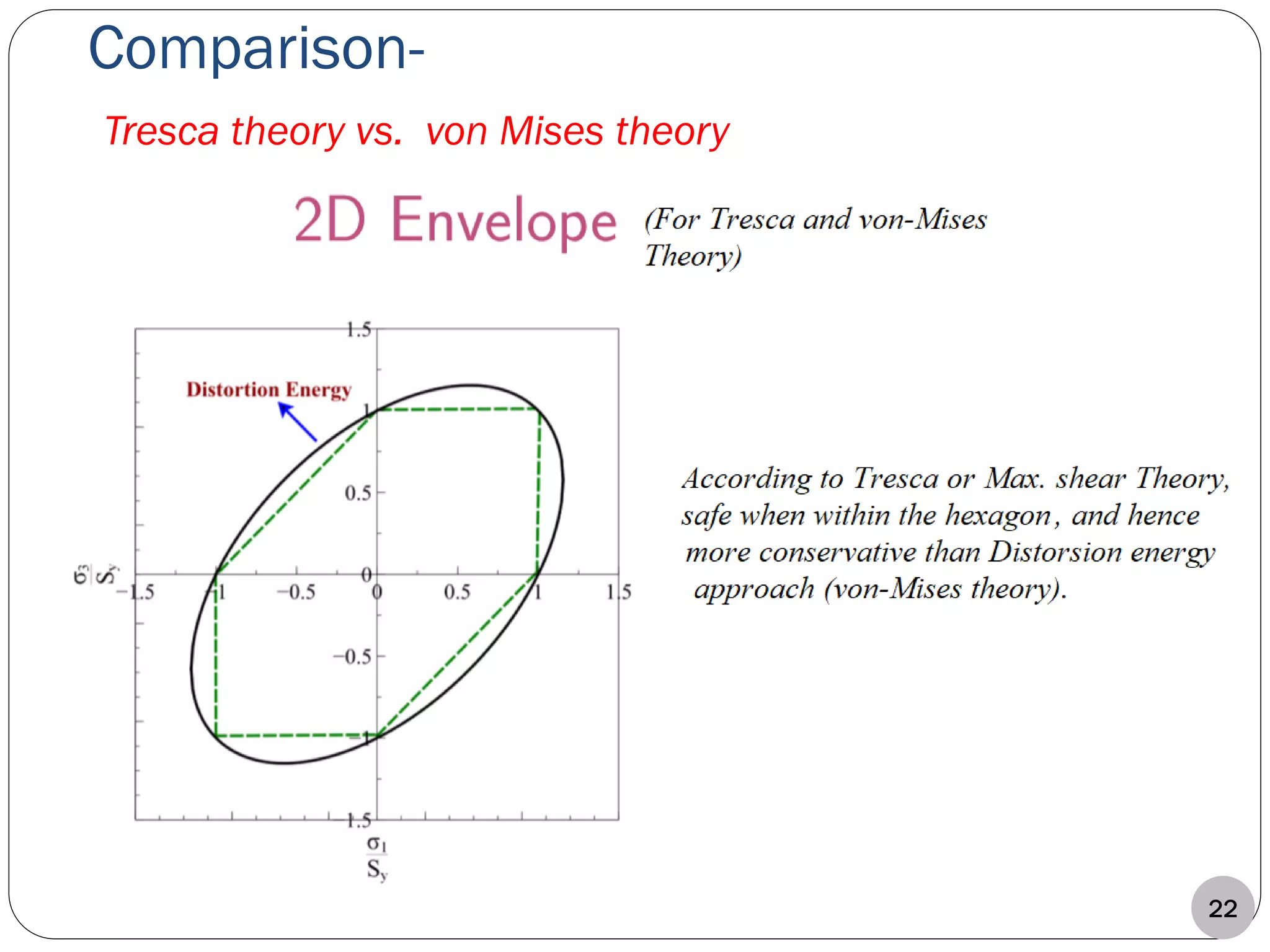

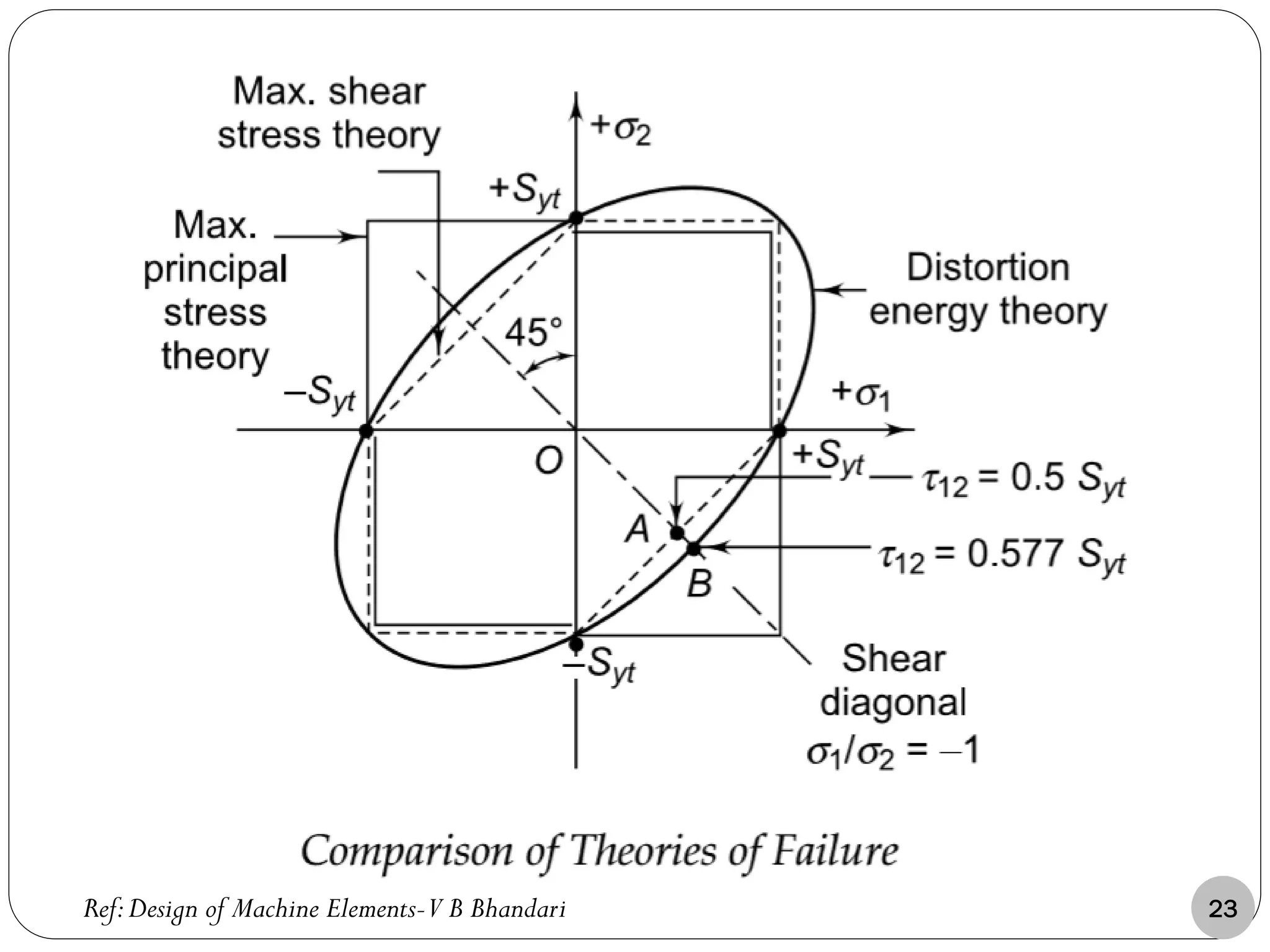

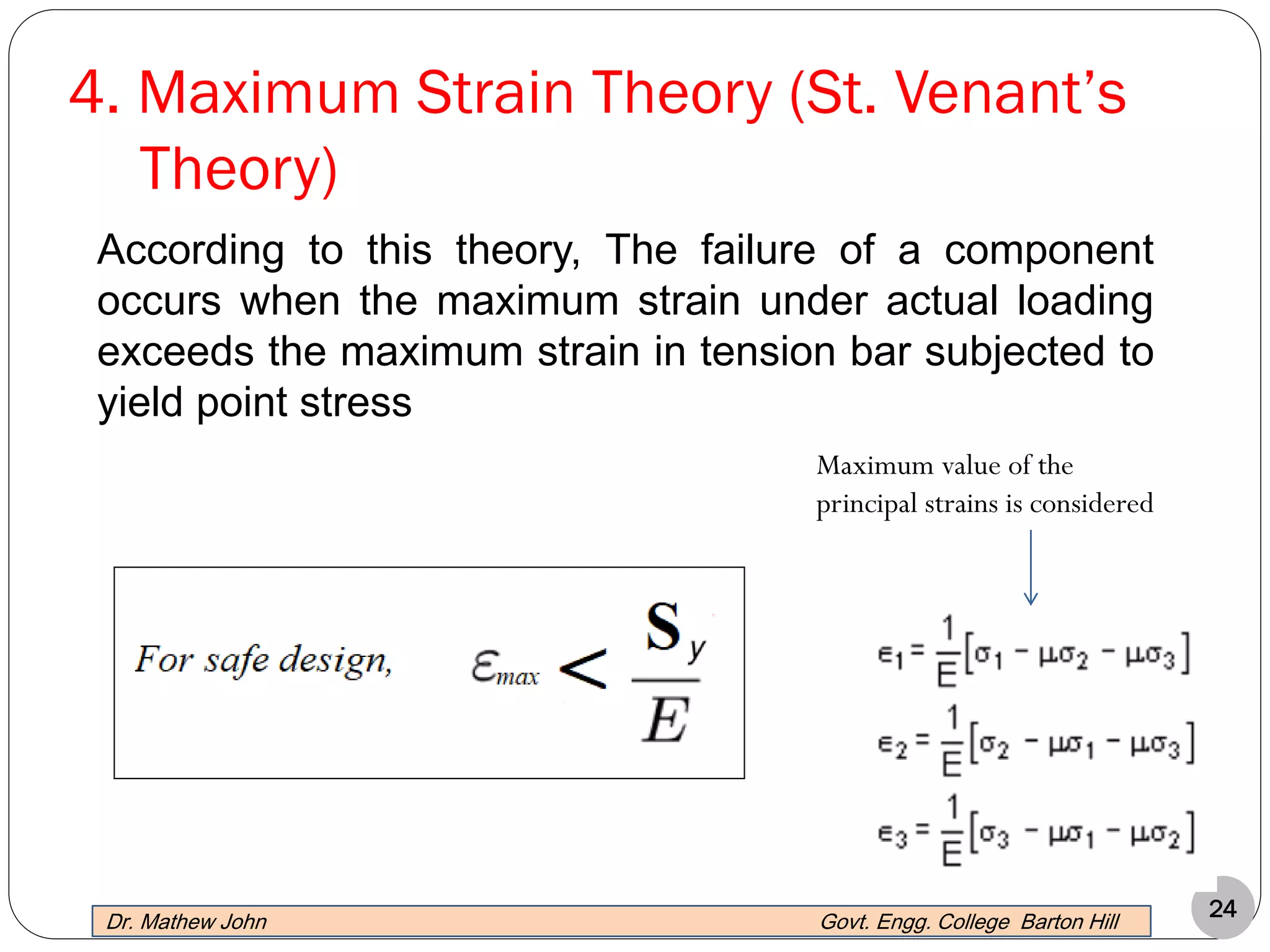

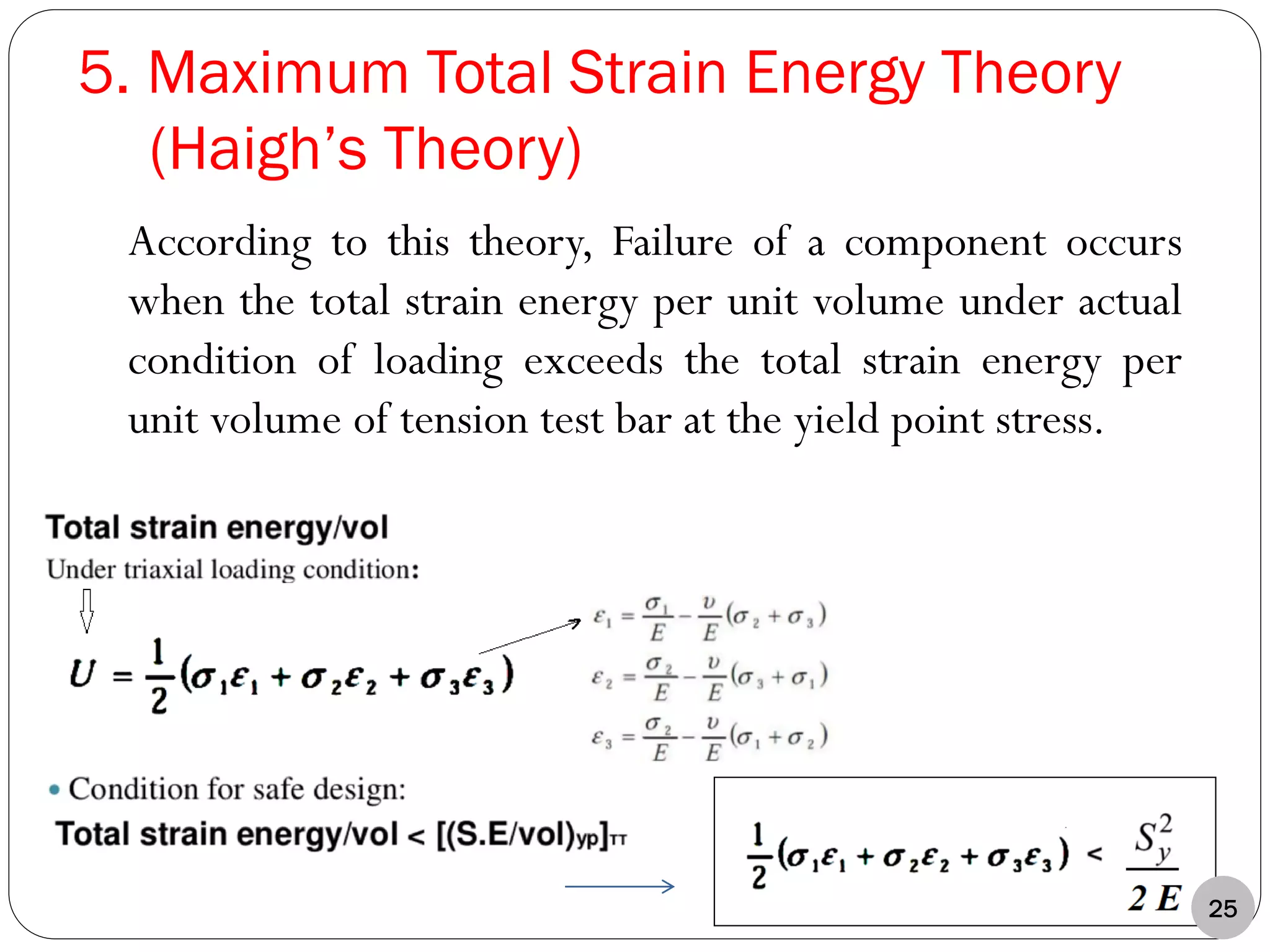

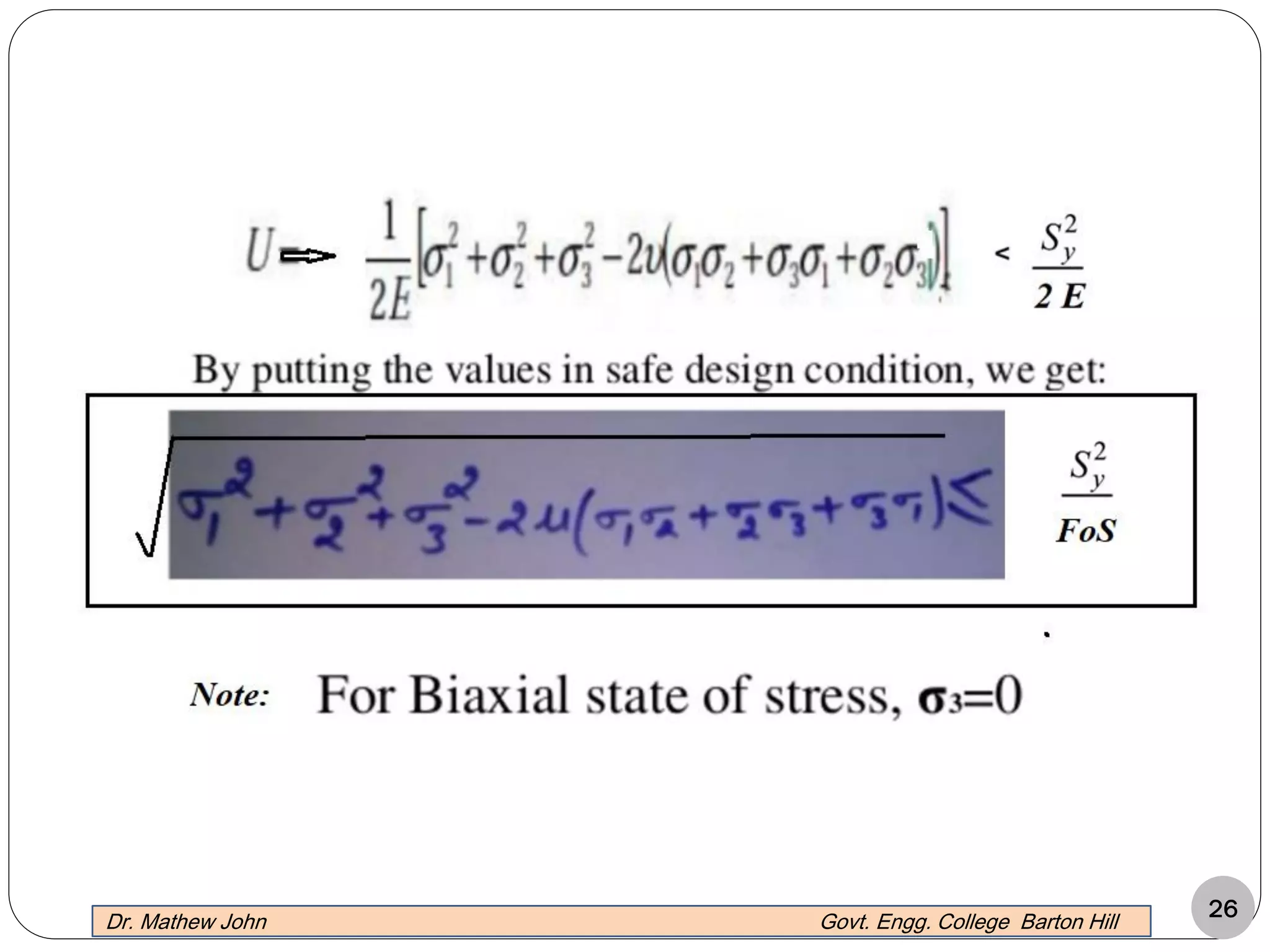

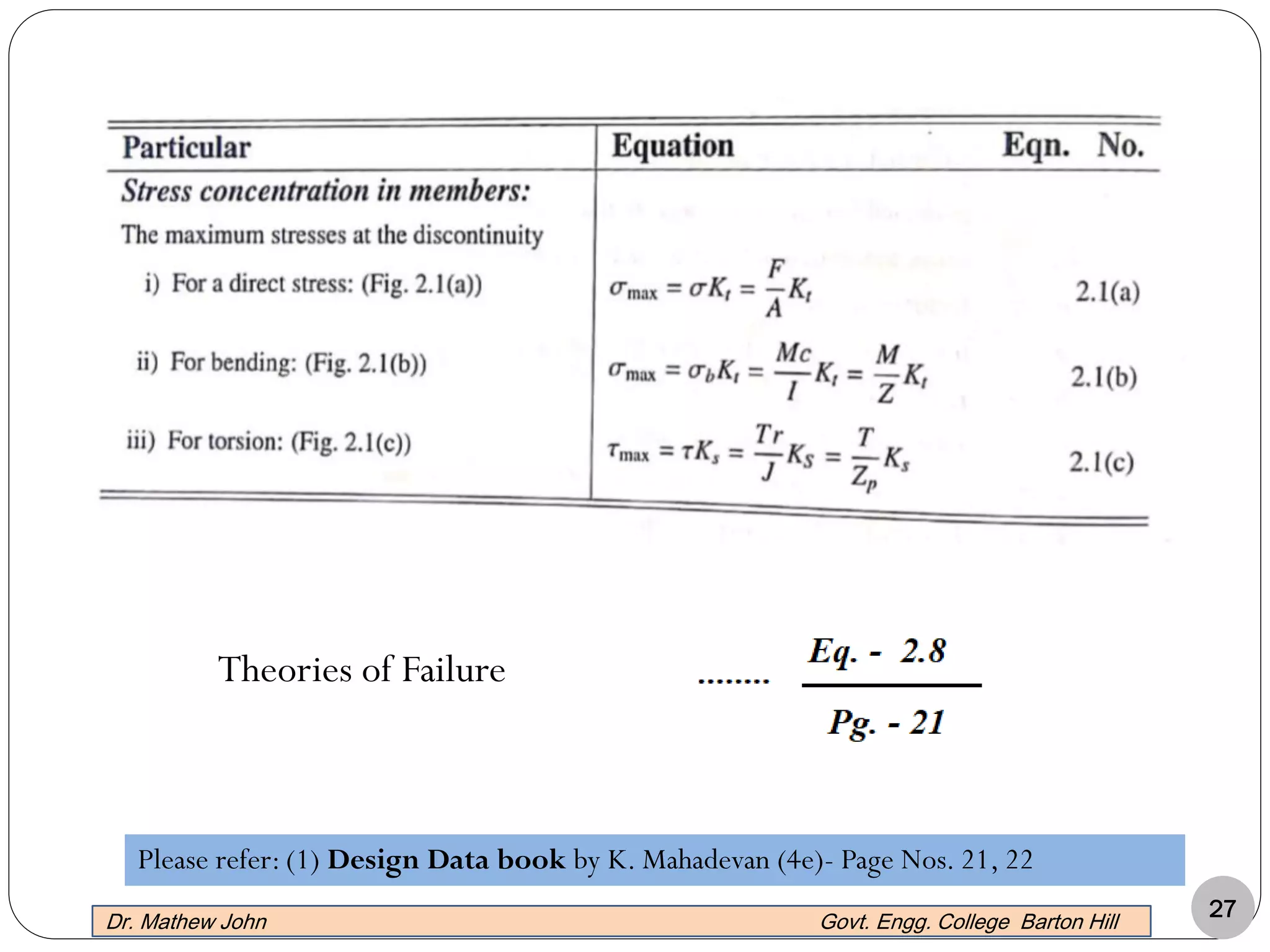

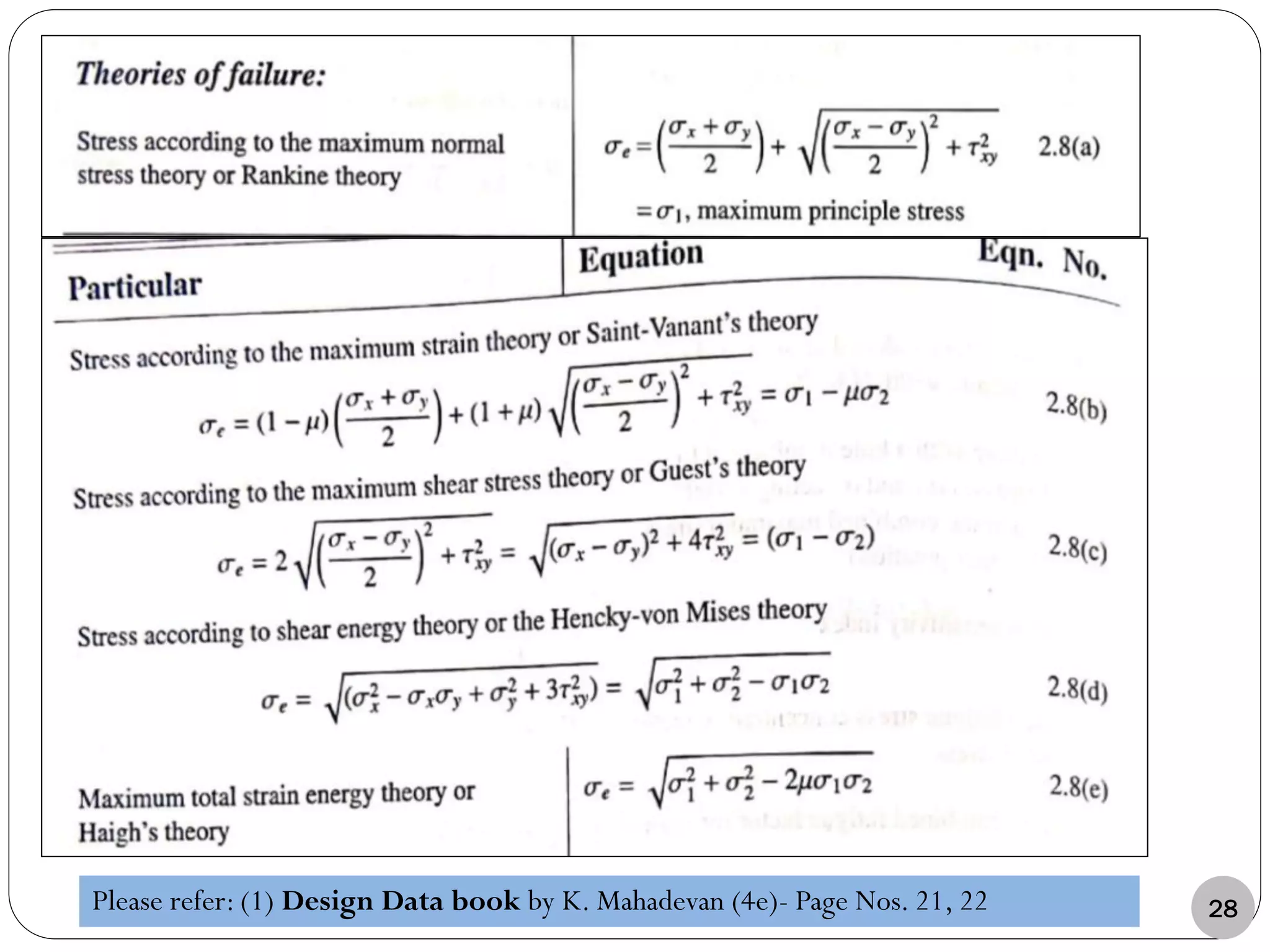

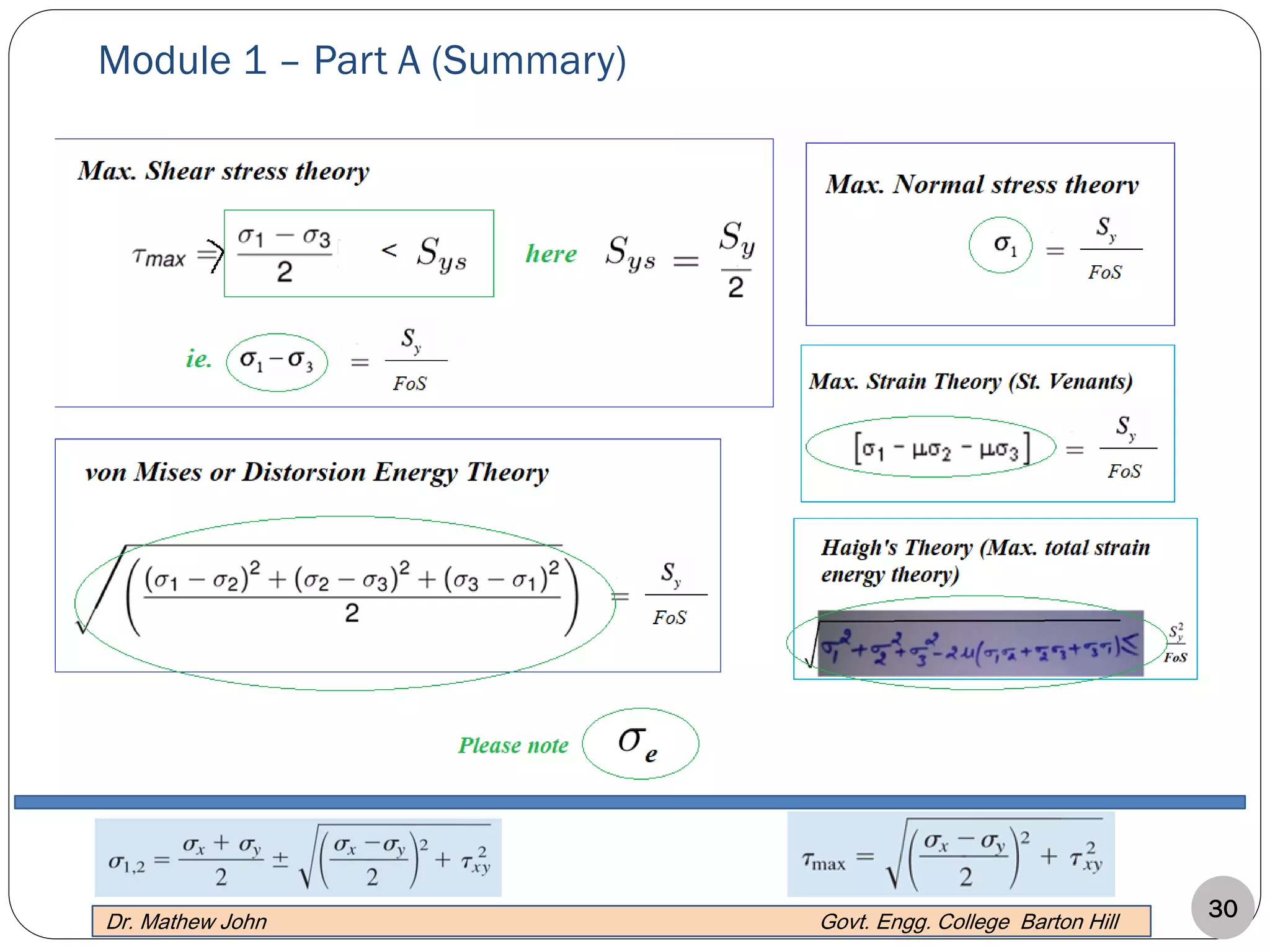

1. The document discusses various theories of failure including maximum shear stress theory, maximum principal stress theory, maximum distortion energy theory, maximum strain theory, and maximum total strain energy theory.

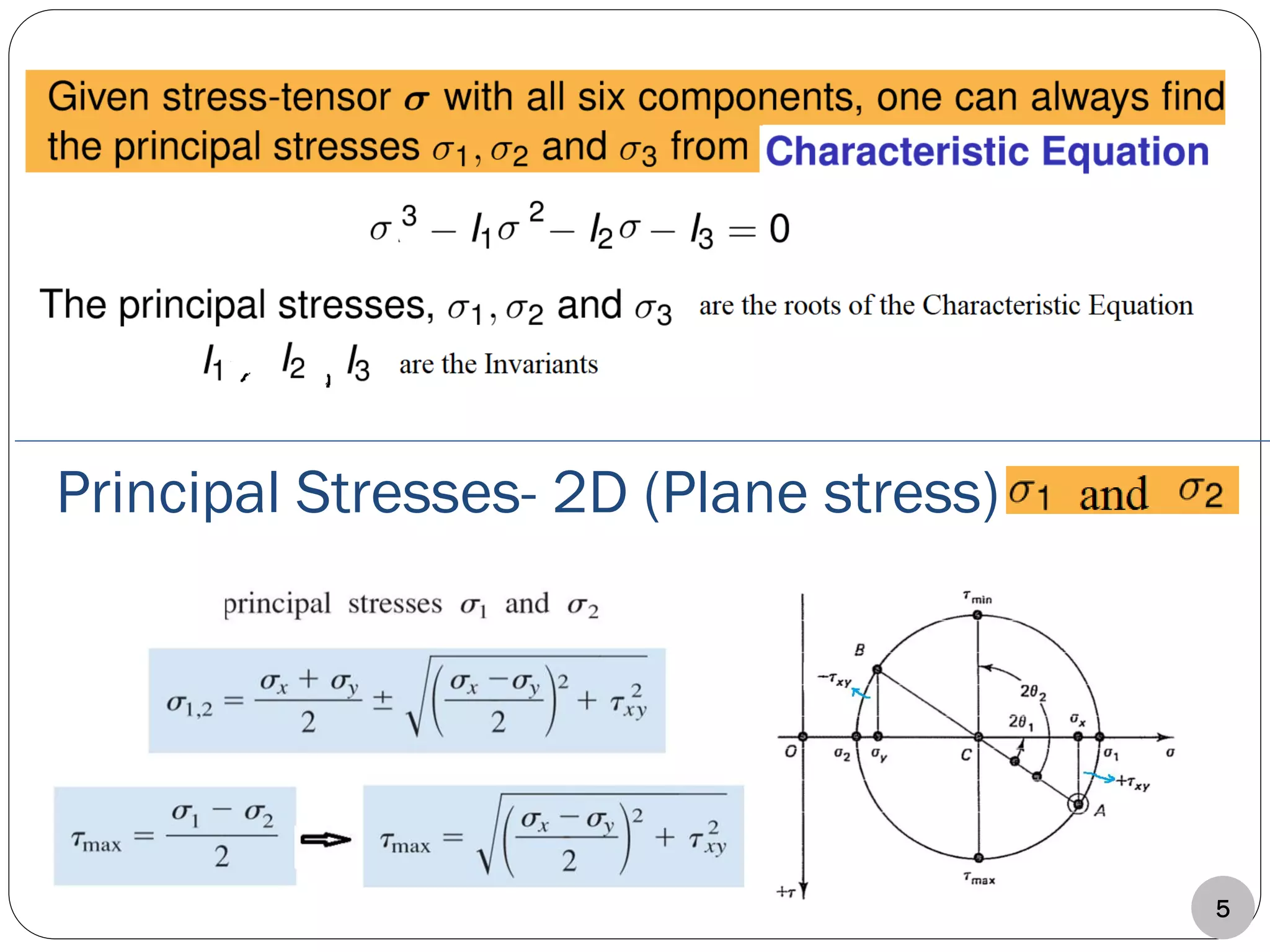

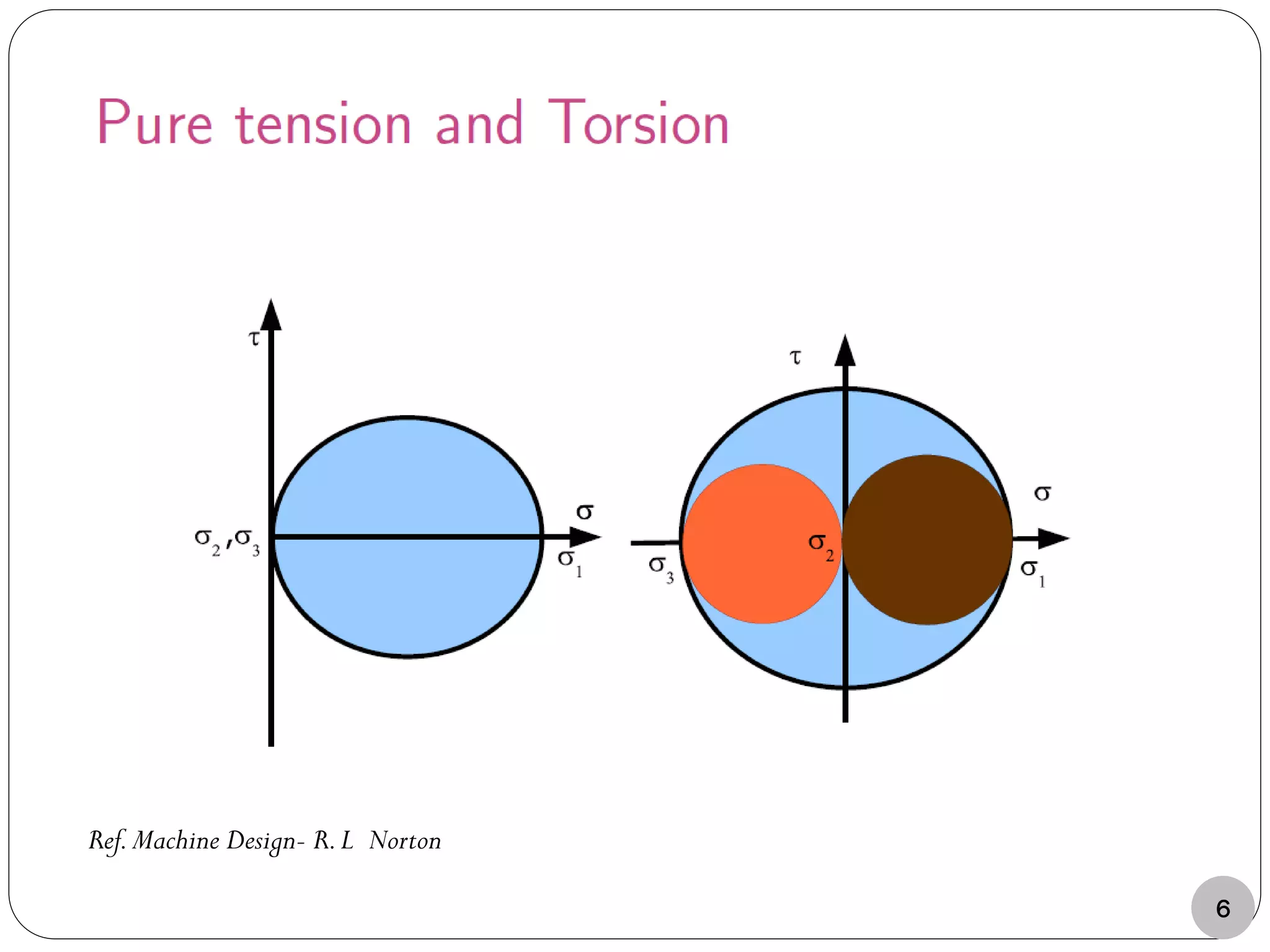

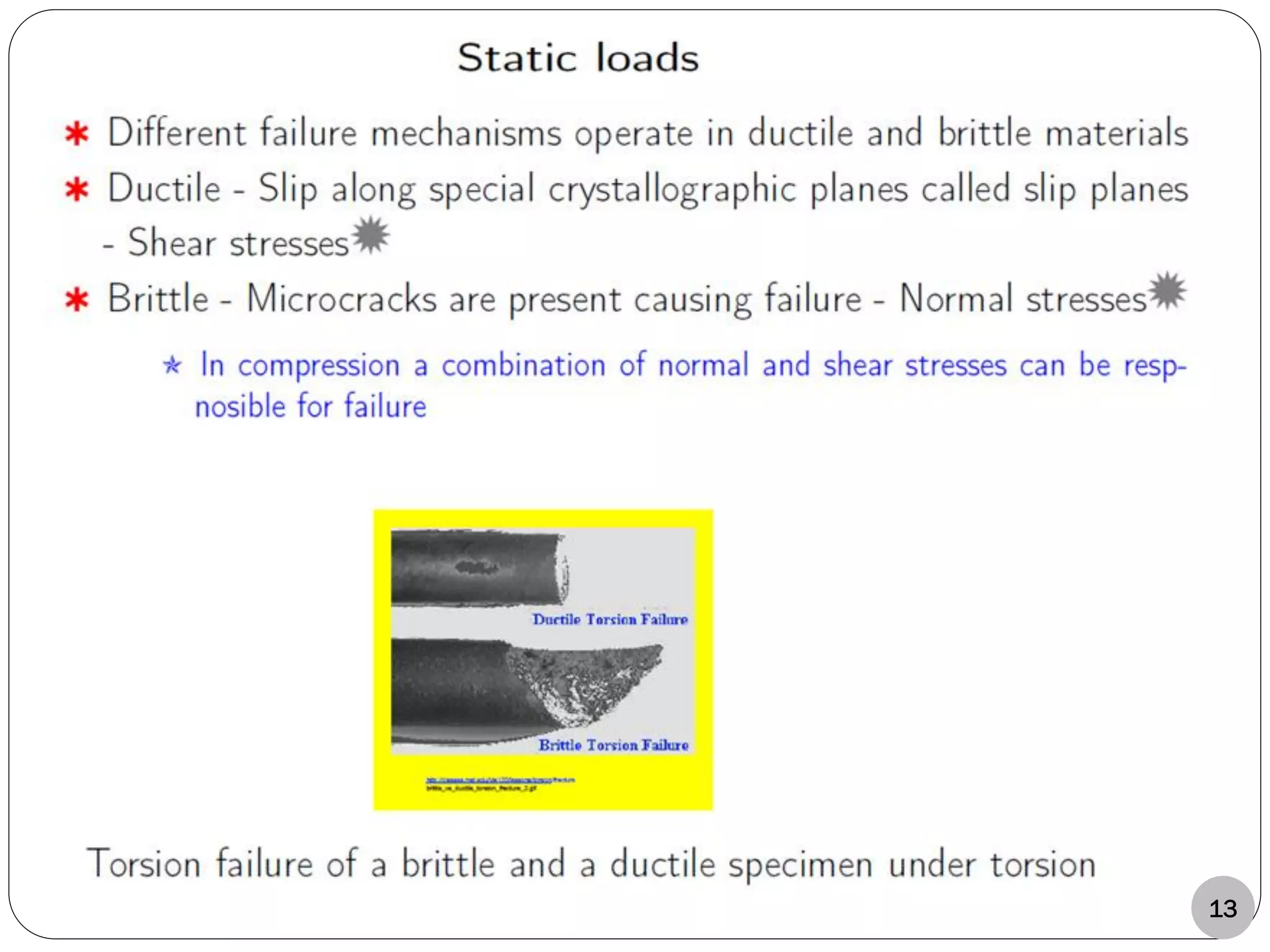

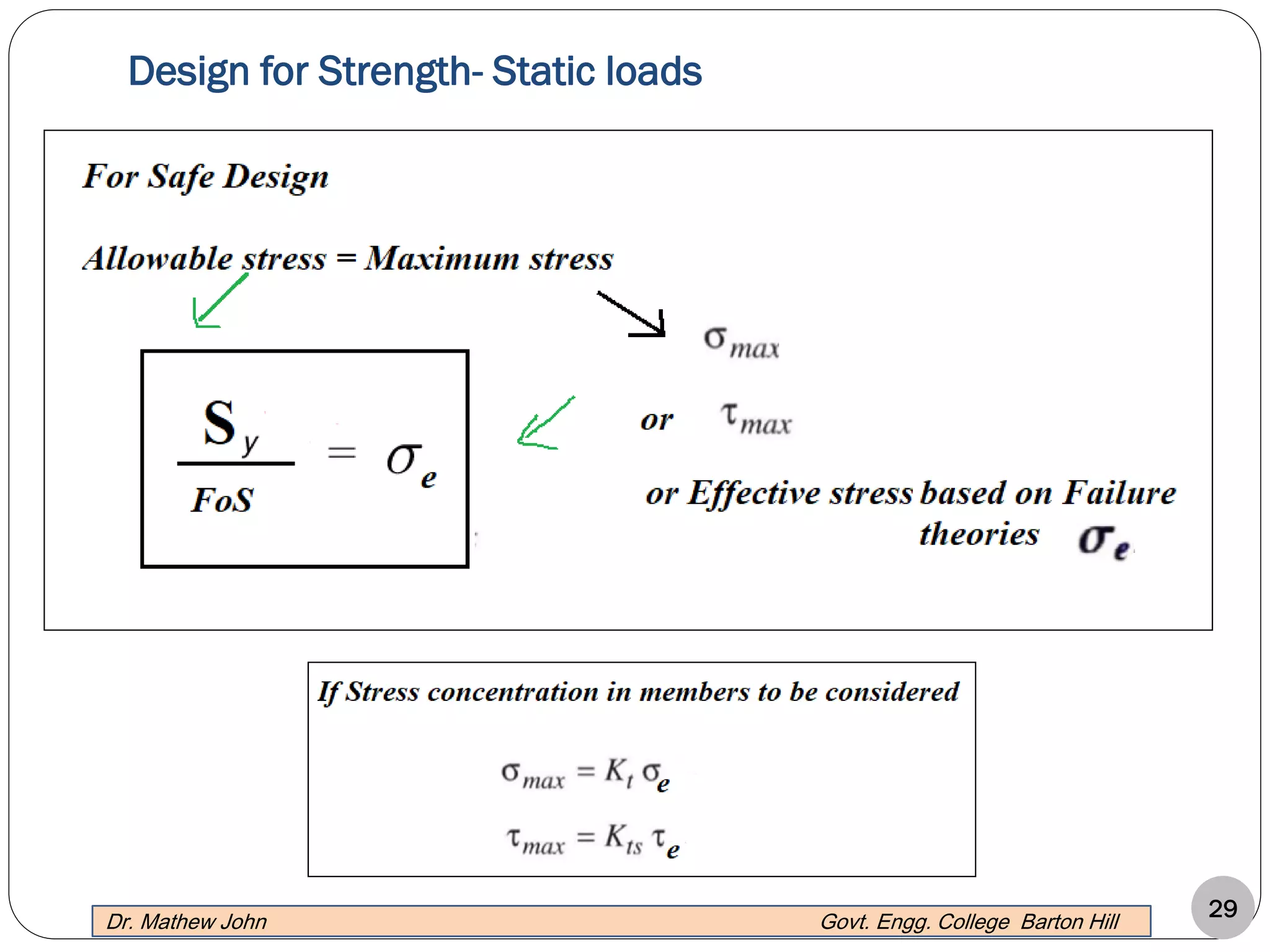

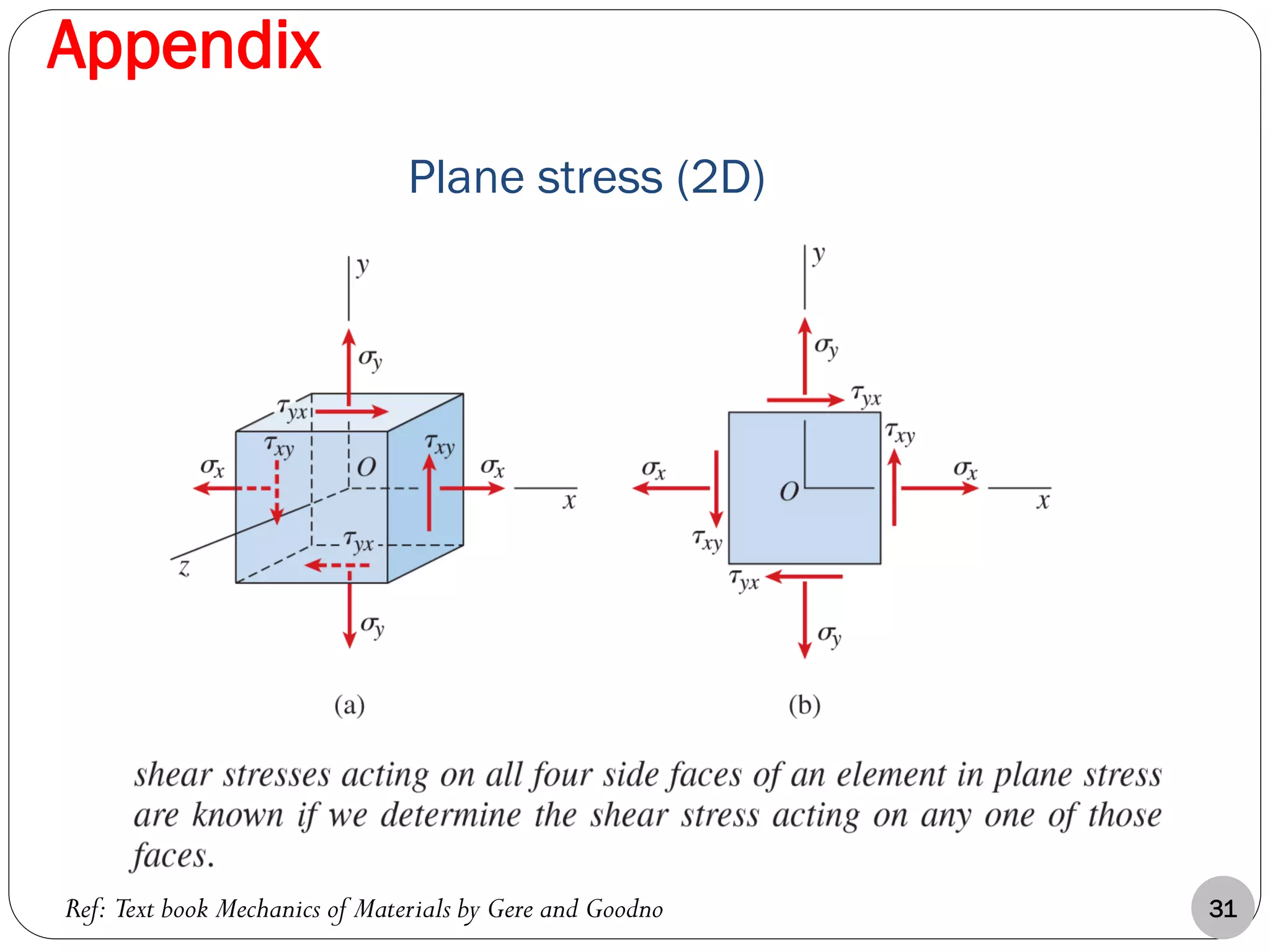

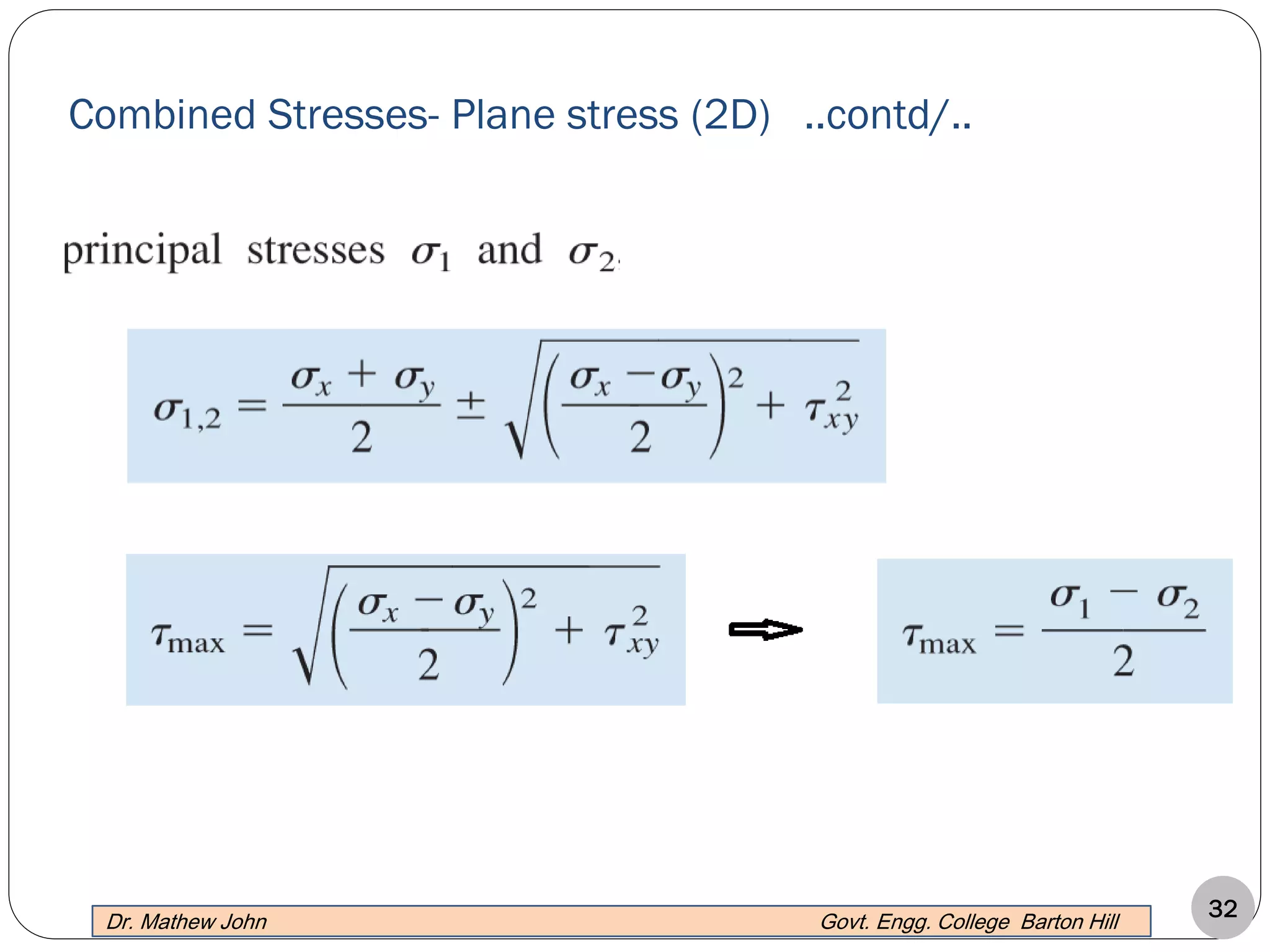

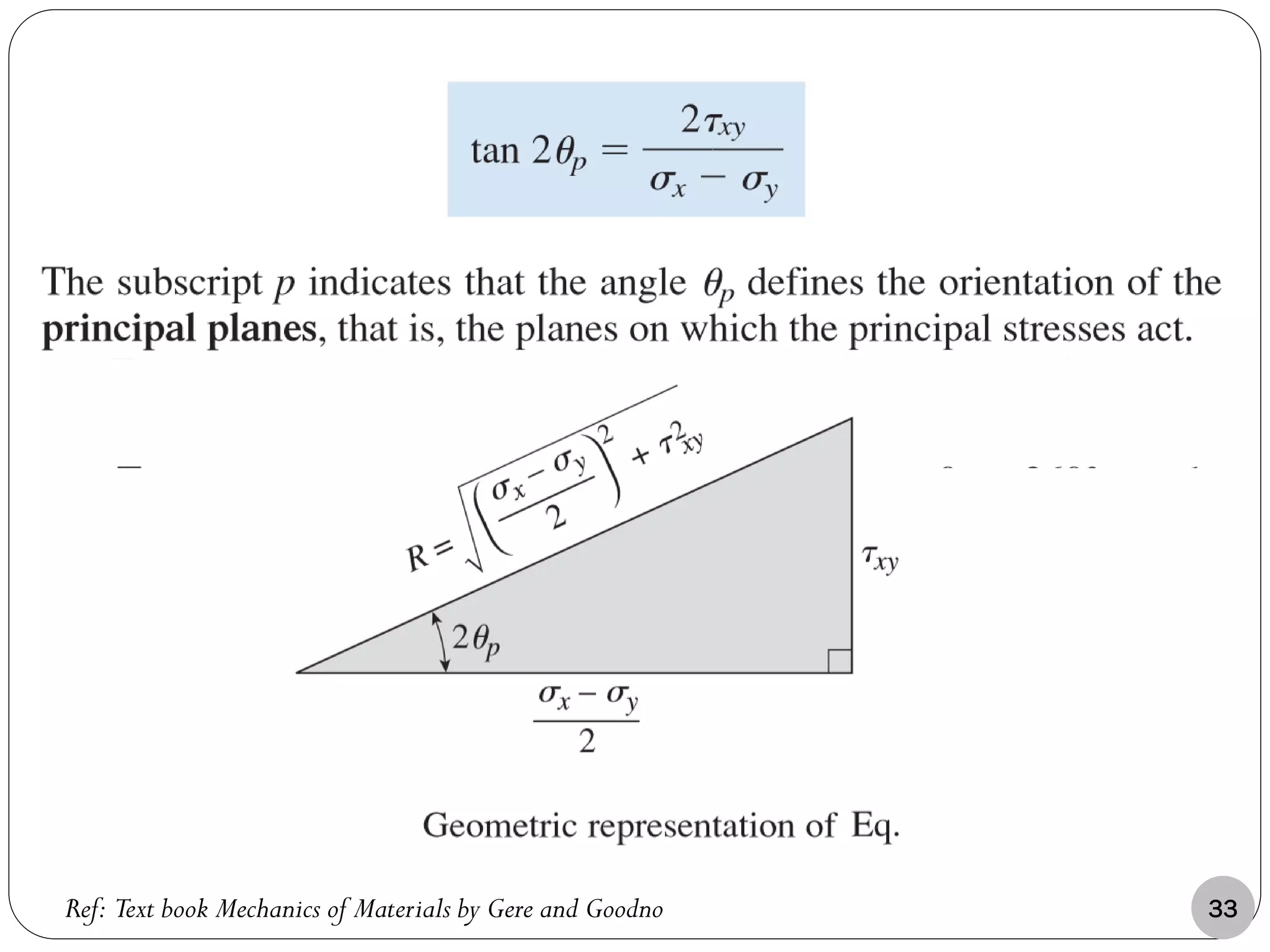

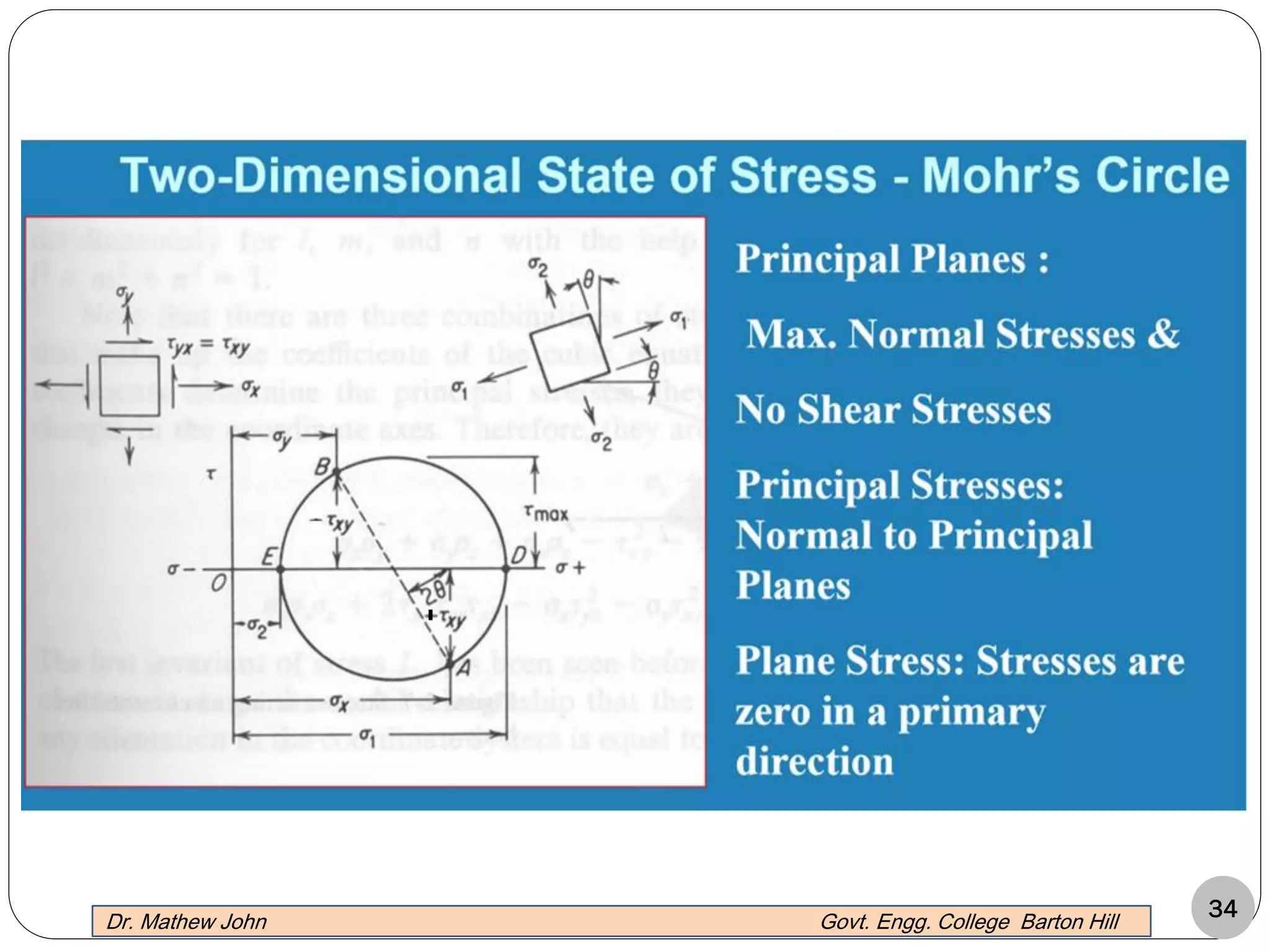

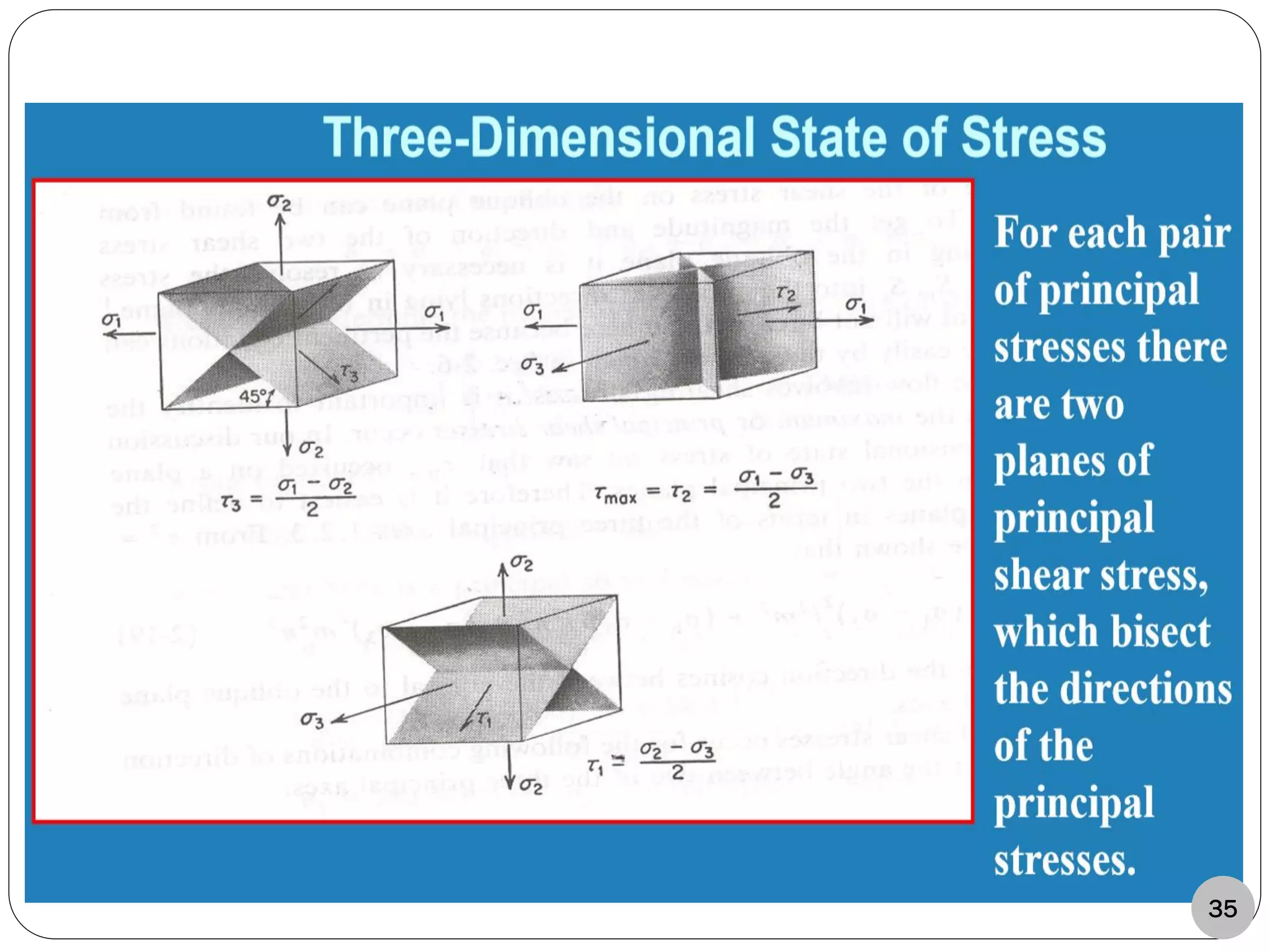

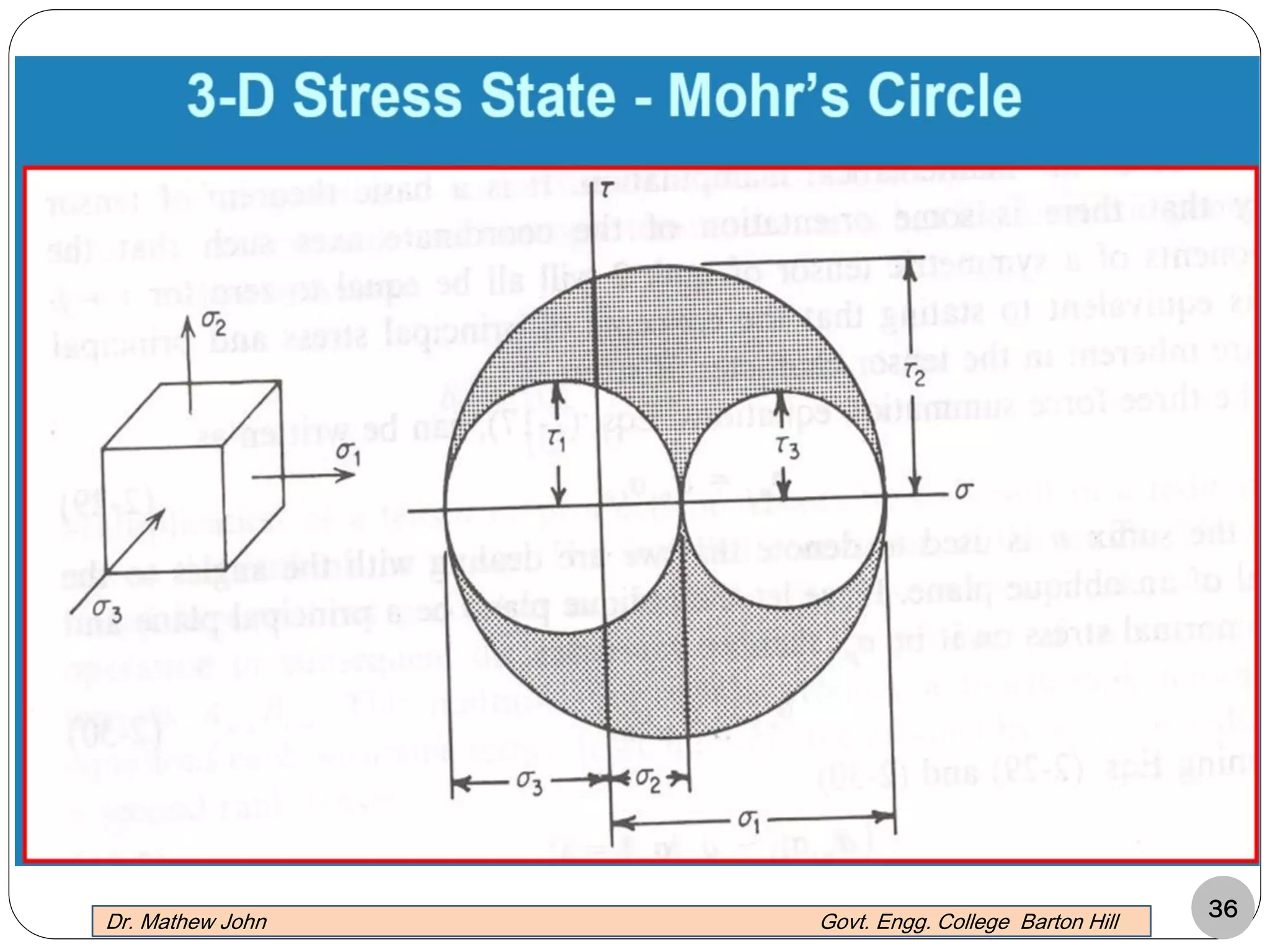

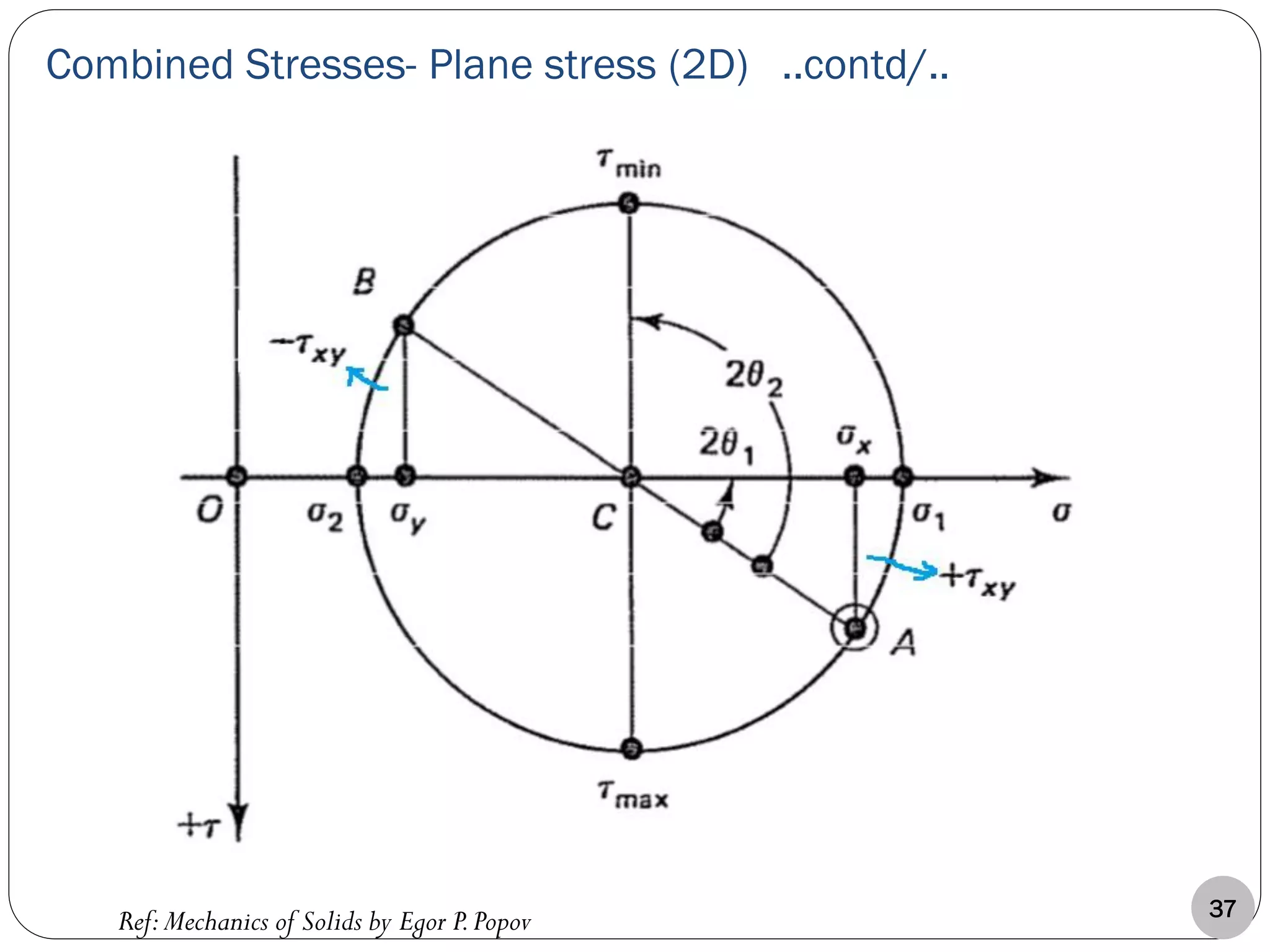

2. It also covers topics like stress tensors, principal stresses, combined stresses, and design for strength under static loads.

3. Examples, equations, and references are provided to explain concepts related to stress analysis and failure theories.