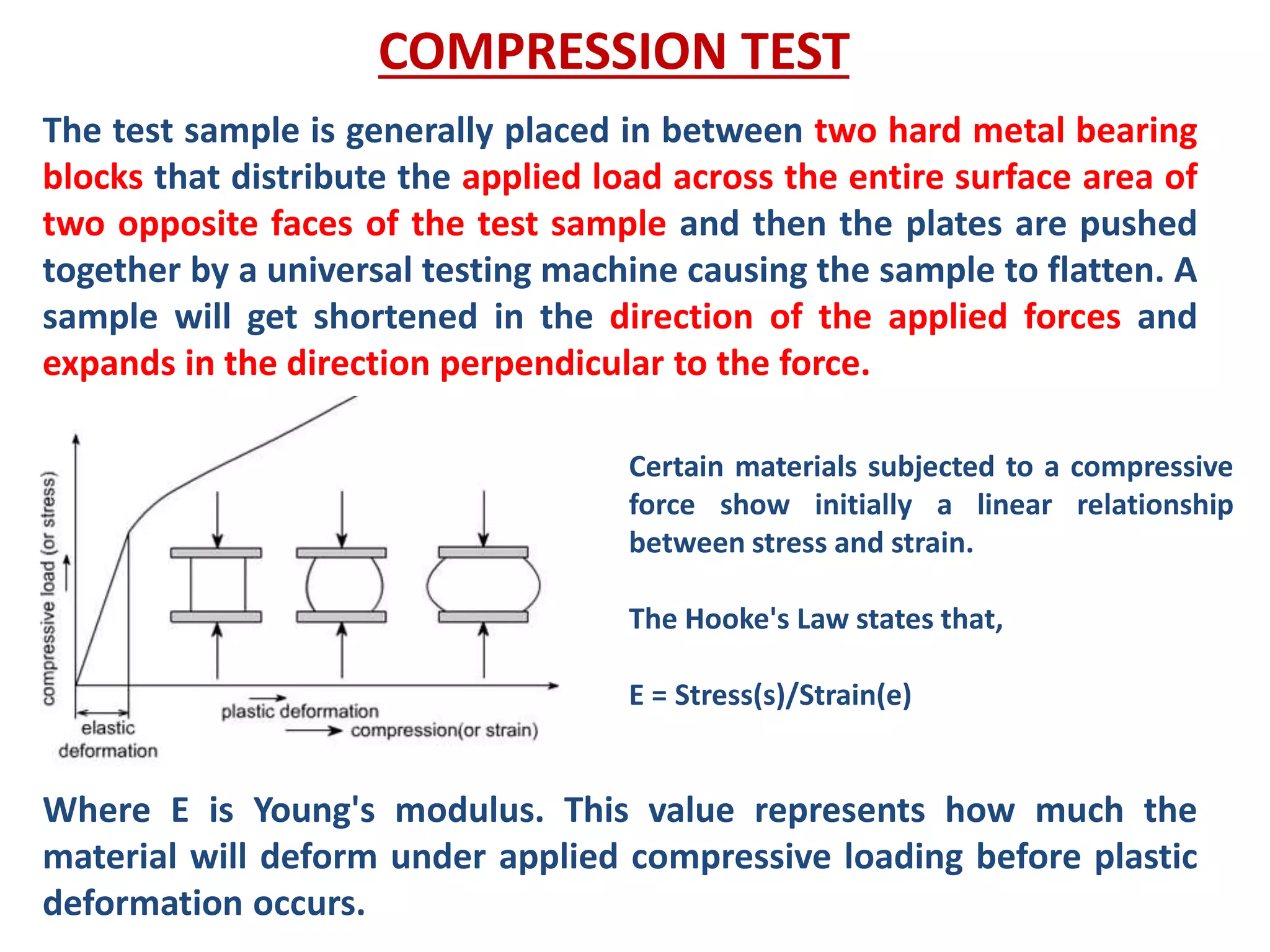

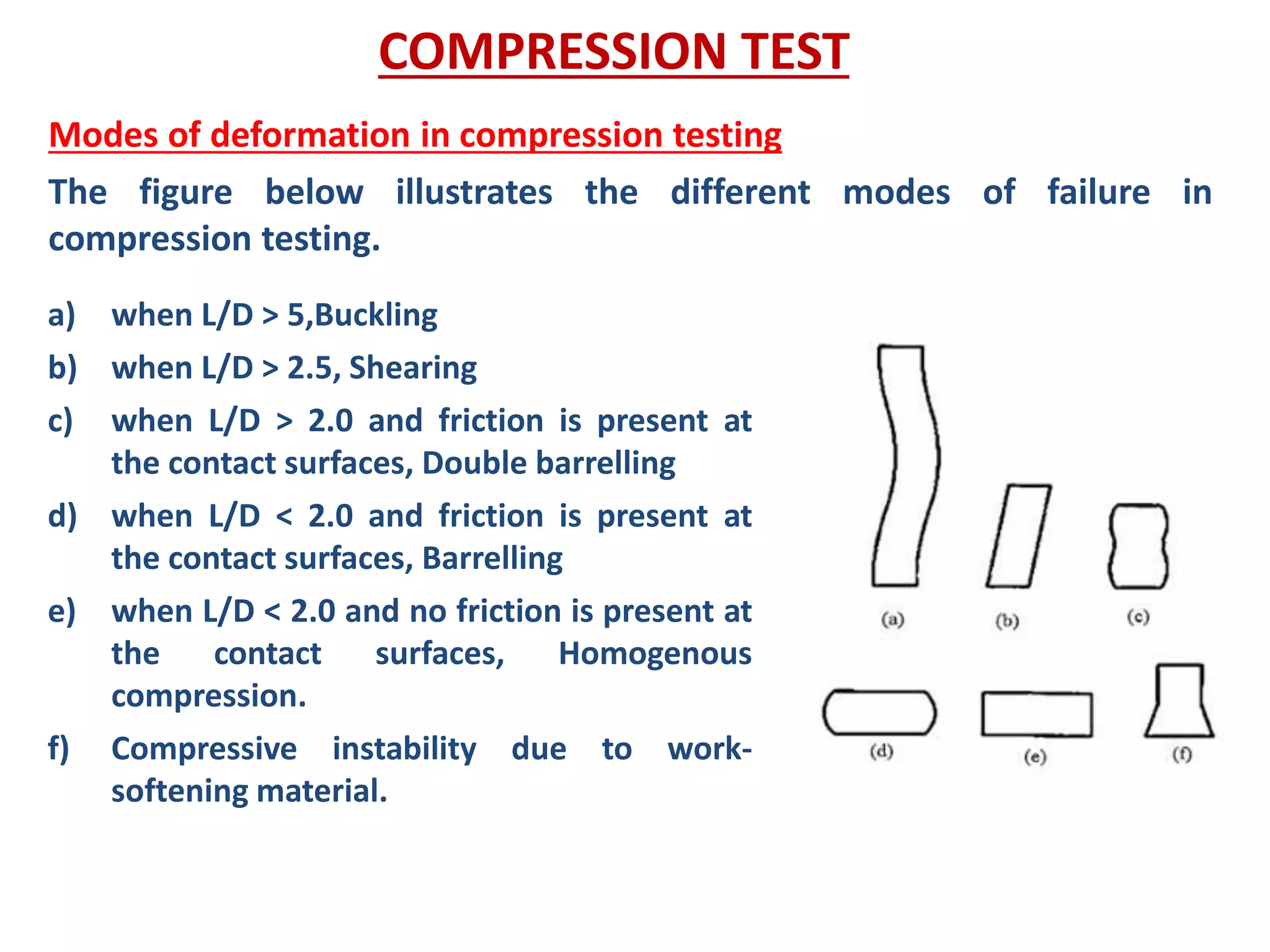

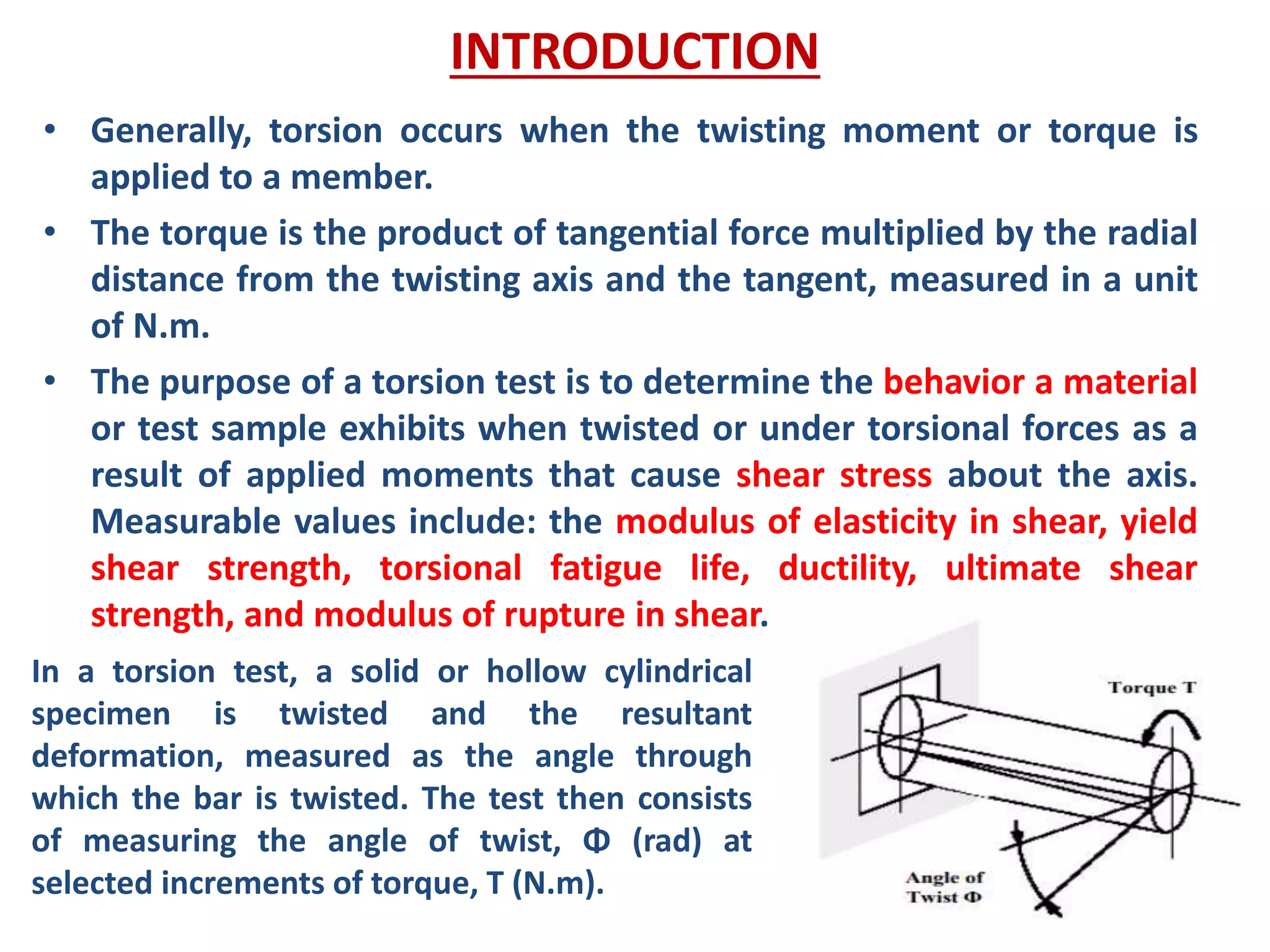

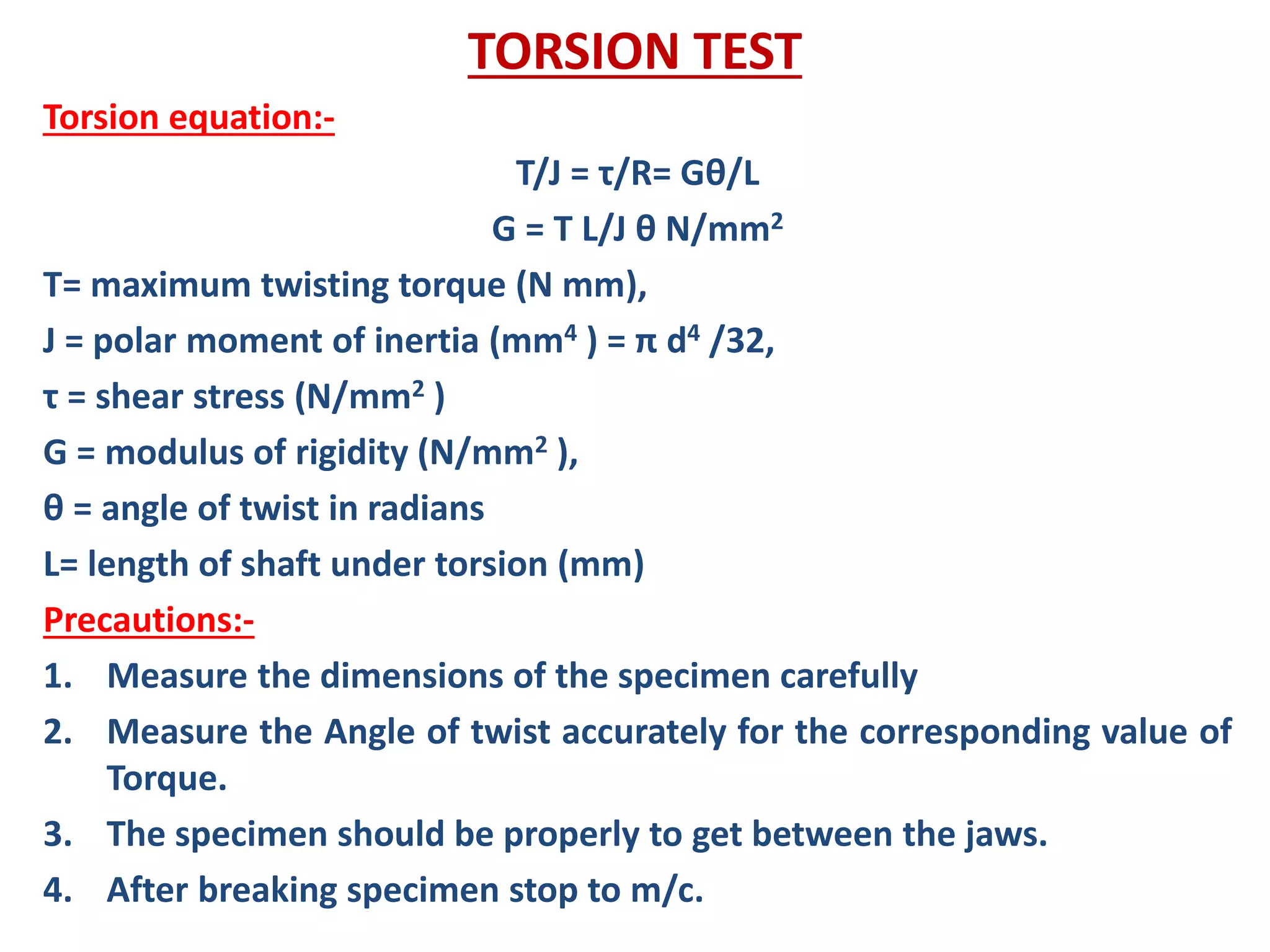

The document discusses compression and torsion testing. Compression testing involves applying compressive pressure to a test specimen to determine its strength and stiffness under crushing loads. Torsion testing involves twisting a cylindrical specimen to measure its behavior under torsional forces and determine properties like shear modulus. Both tests are useful for obtaining mechanical properties of materials and evaluating their performance under different types of stresses.