This document provides an overview of topics related to simple stresses and strains, including:

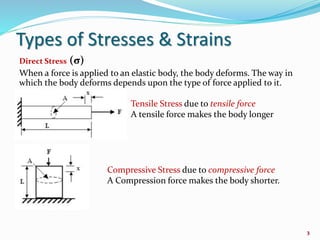

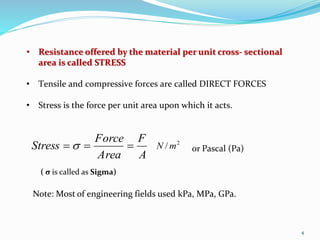

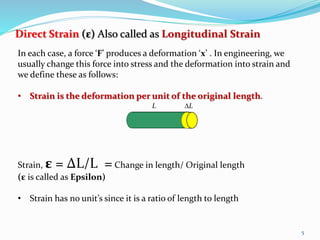

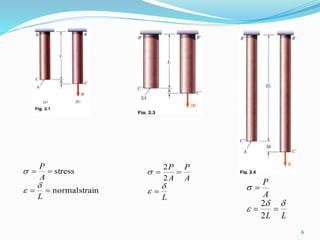

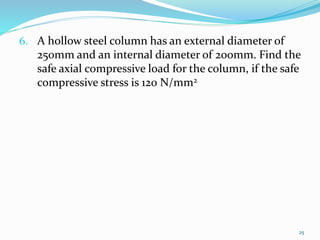

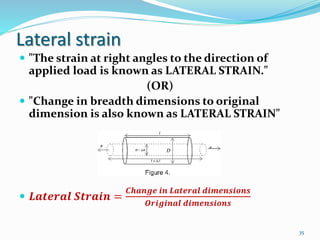

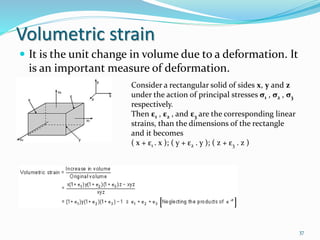

- Types of stresses and strains such as tensile, compressive, direct stress, and direct strain.

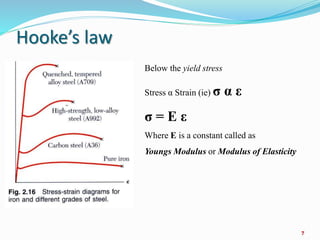

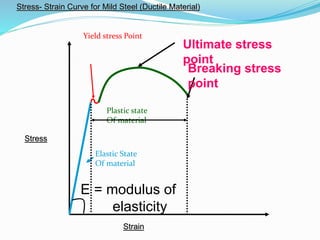

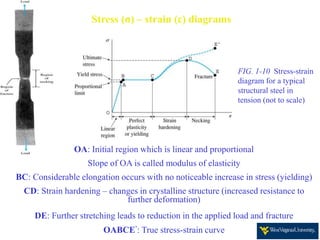

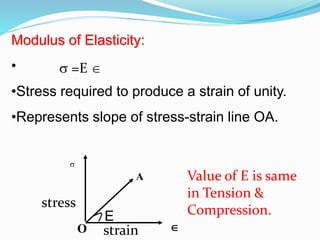

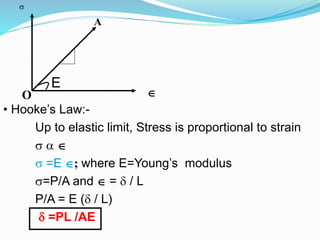

- Hooke's law and how stress is proportional to strain below the material's yield point.

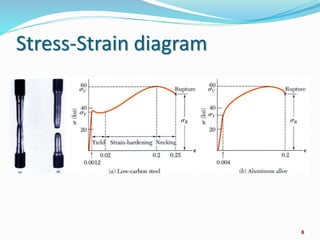

- Stress-strain diagrams and key points such as the elastic region, yield point, and fracture point.

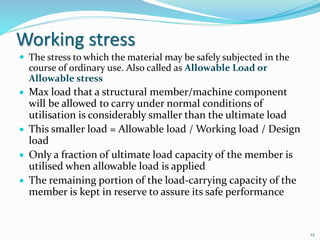

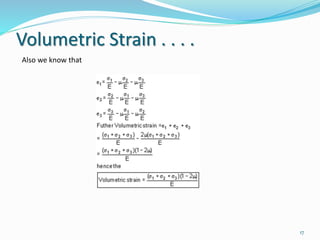

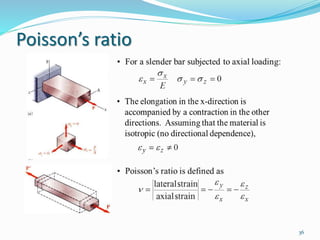

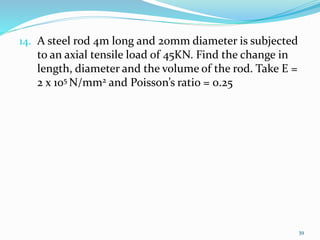

- Definitions of terms like working stress, factor of safety, Poisson's ratio, and elastic moduli.

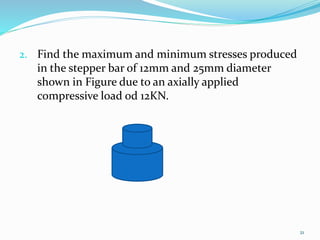

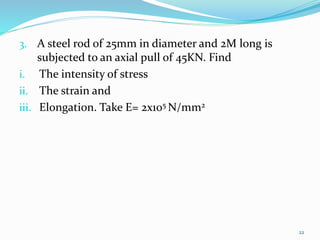

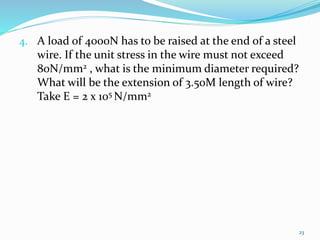

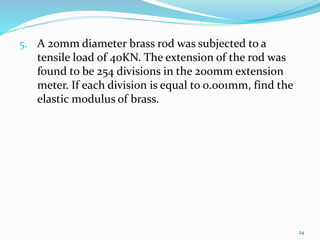

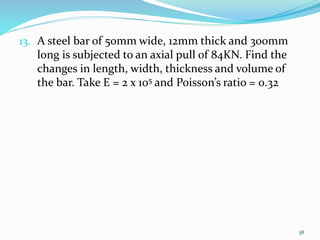

- Examples of problems calculating stresses, strains, extensions, and deformations of simple structural members under various loads.