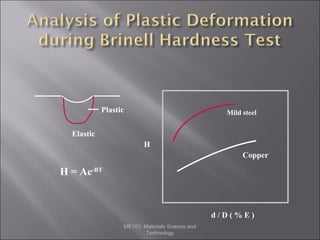

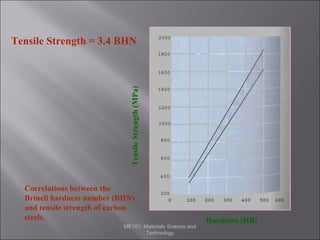

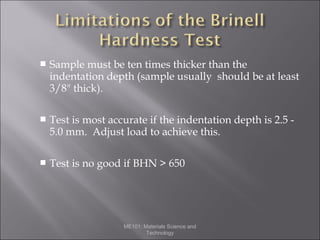

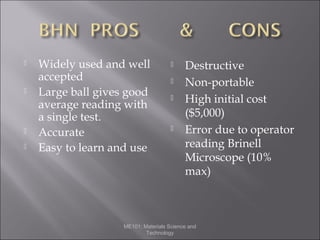

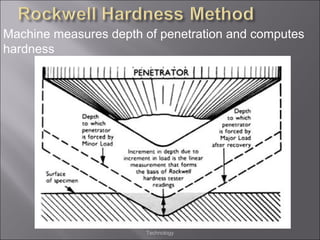

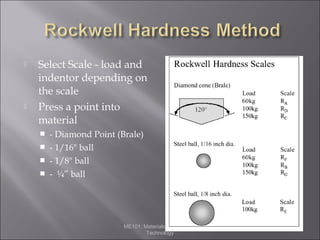

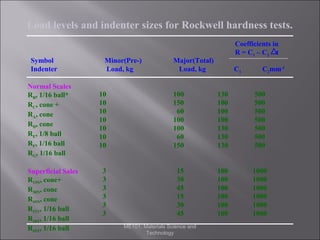

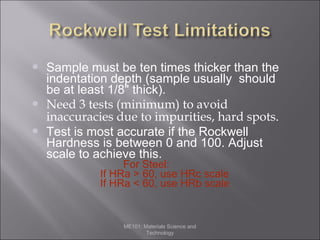

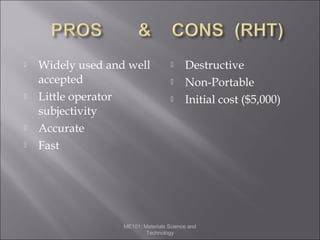

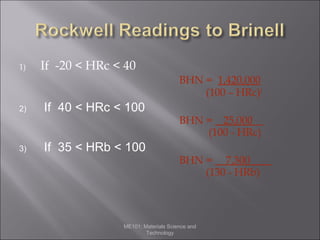

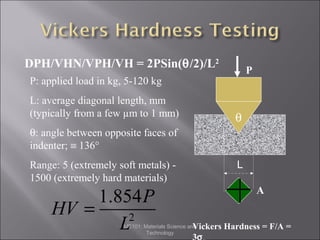

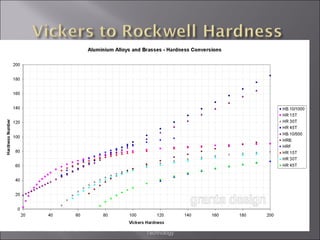

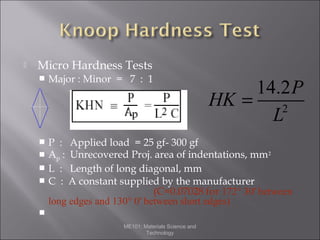

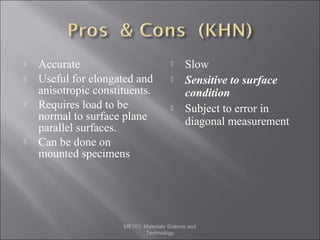

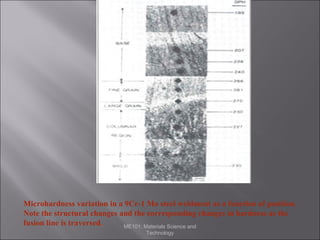

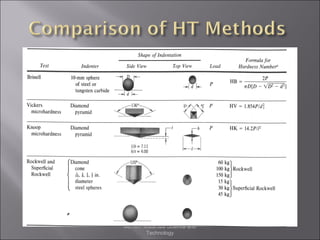

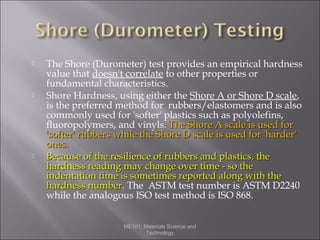

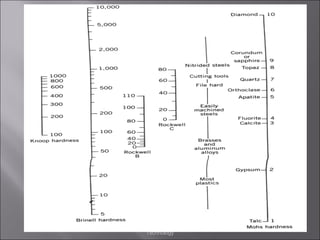

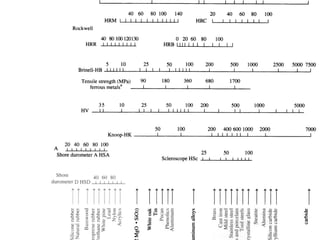

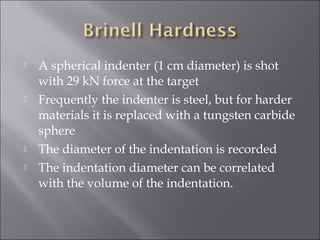

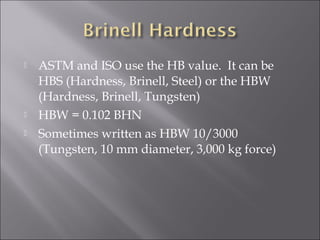

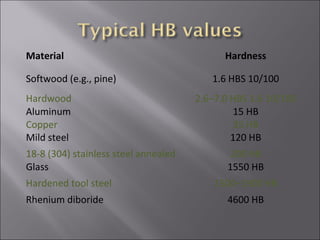

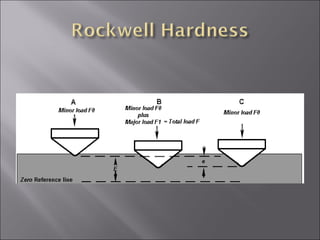

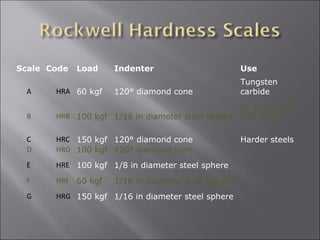

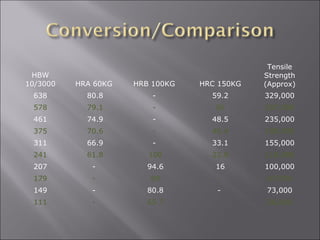

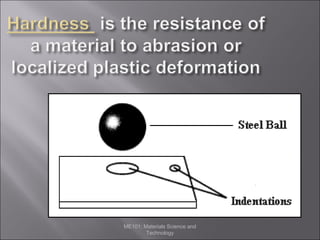

The document provides information about different hardness tests for materials, including Brinell hardness test, Rockwell hardness test, and Vickers hardness test. It explains how each test is conducted, the equipment used, factors that influence the measurements, advantages and disadvantages of the tests. Correlations between hardness values and properties like tensile strength are also discussed. Various hardness scales are compared. Microhardness testing and applications are outlined as well.

![1.

2.

3.

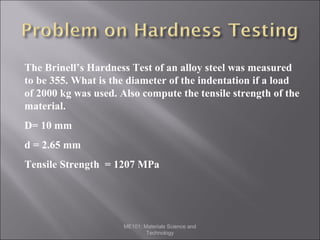

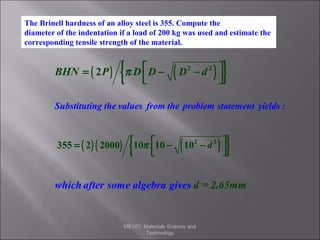

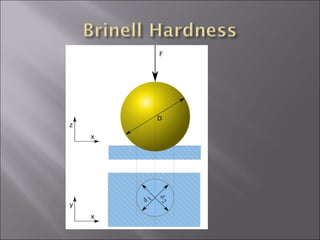

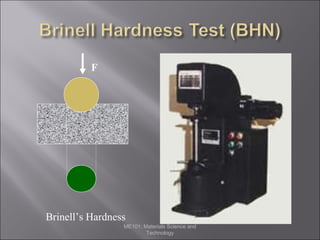

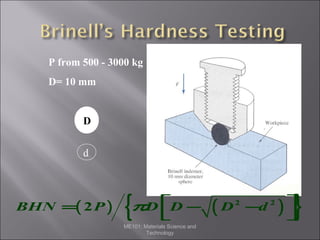

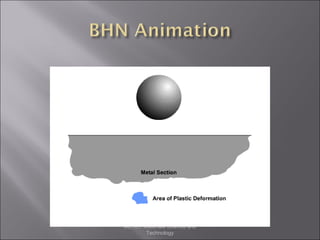

Press a 10mm (3/8") diameter ball into

material with a known amount of load.

Measure diameter of the indentation.

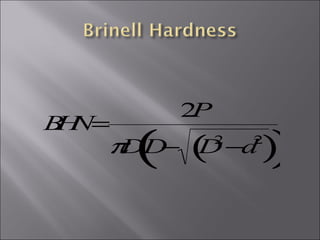

BHN =

Load

=

2L

Surface Area πD[D-(D2-d2)1/2]

1. L = Load placed on ball, usually 3000 kg , but 1500 kg, and

500 kg can also be used.

2. D = Diameter of steel ball ( = 10 mm)

3. d = diameter of dent, measured by looking thru a Brinell

microscope.

ME101: Materials Science and

Technology](https://image.slidesharecdn.com/vgooghardness-131109231658-phpapp02/85/Presentation-on-Hardness-Testing-8-320.jpg)