Embed presentation

Downloaded 225 times

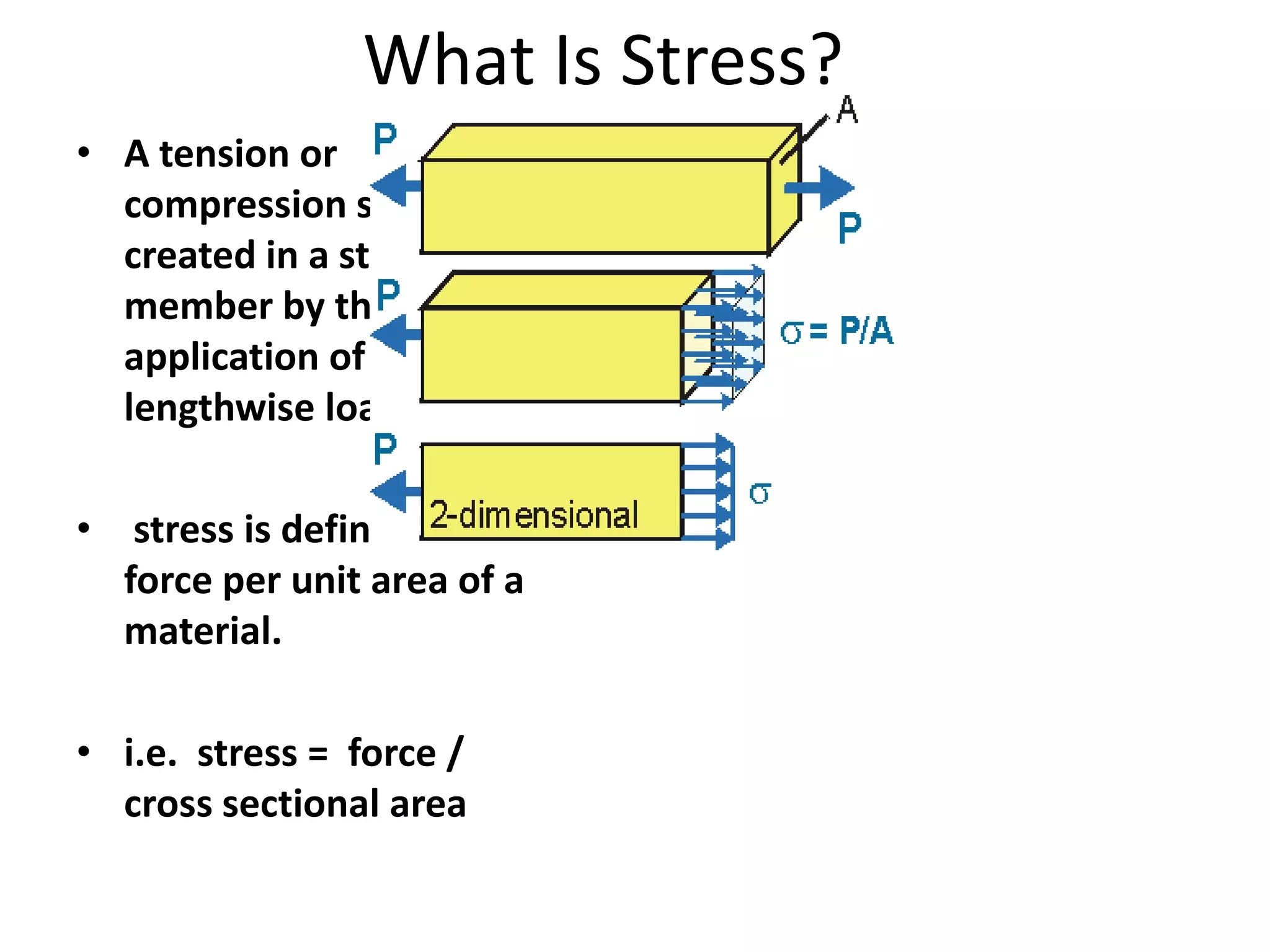

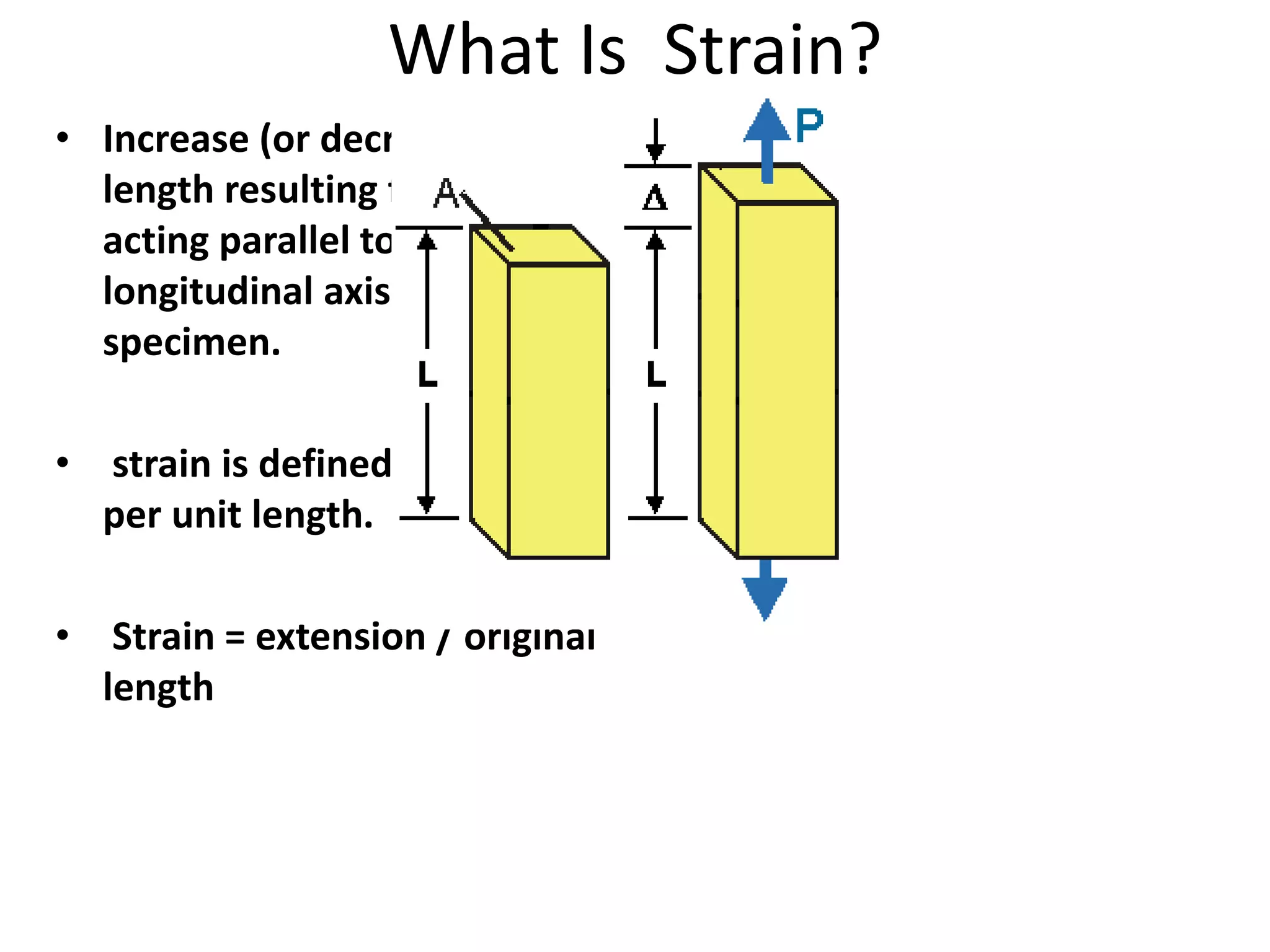

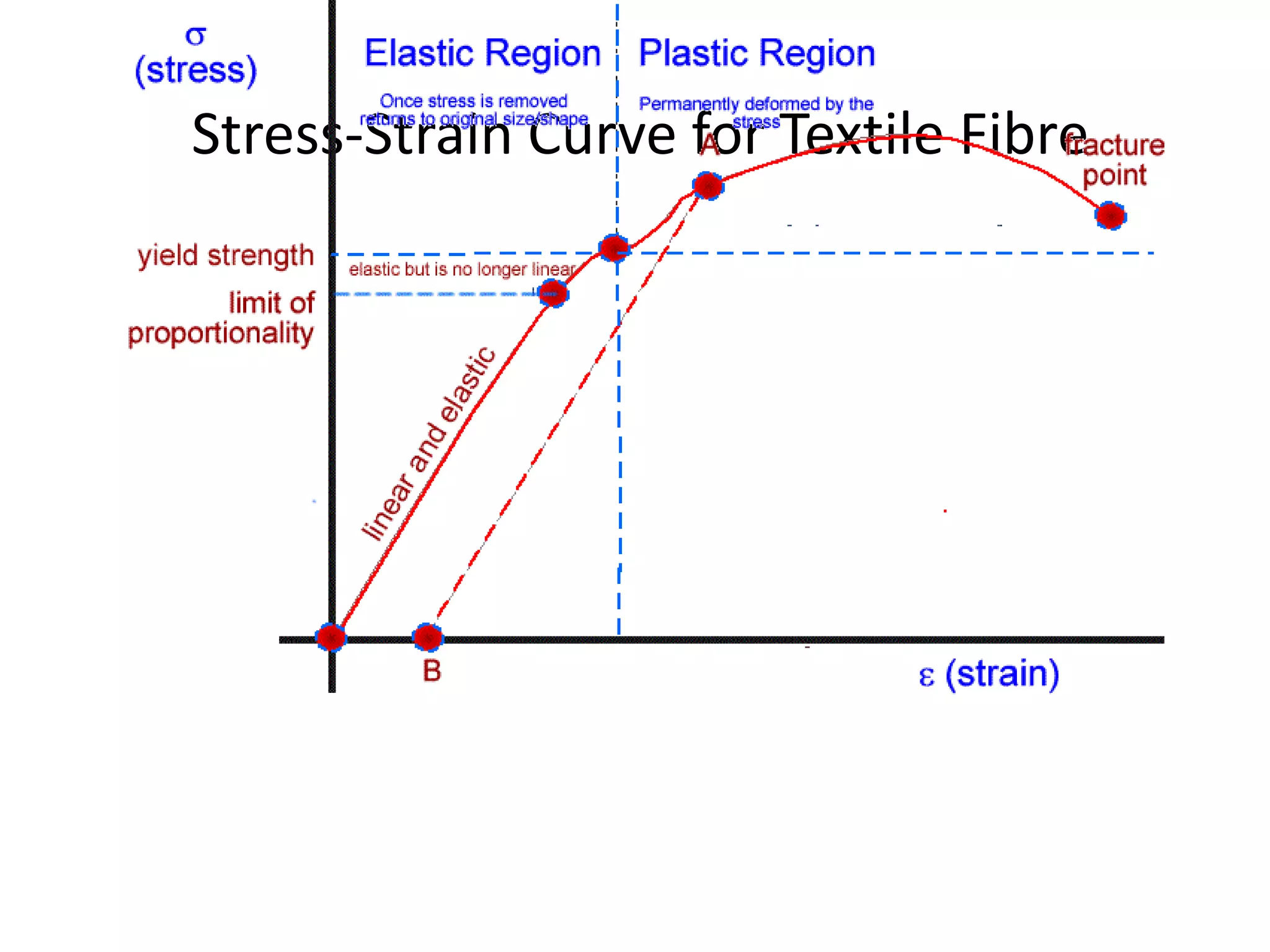

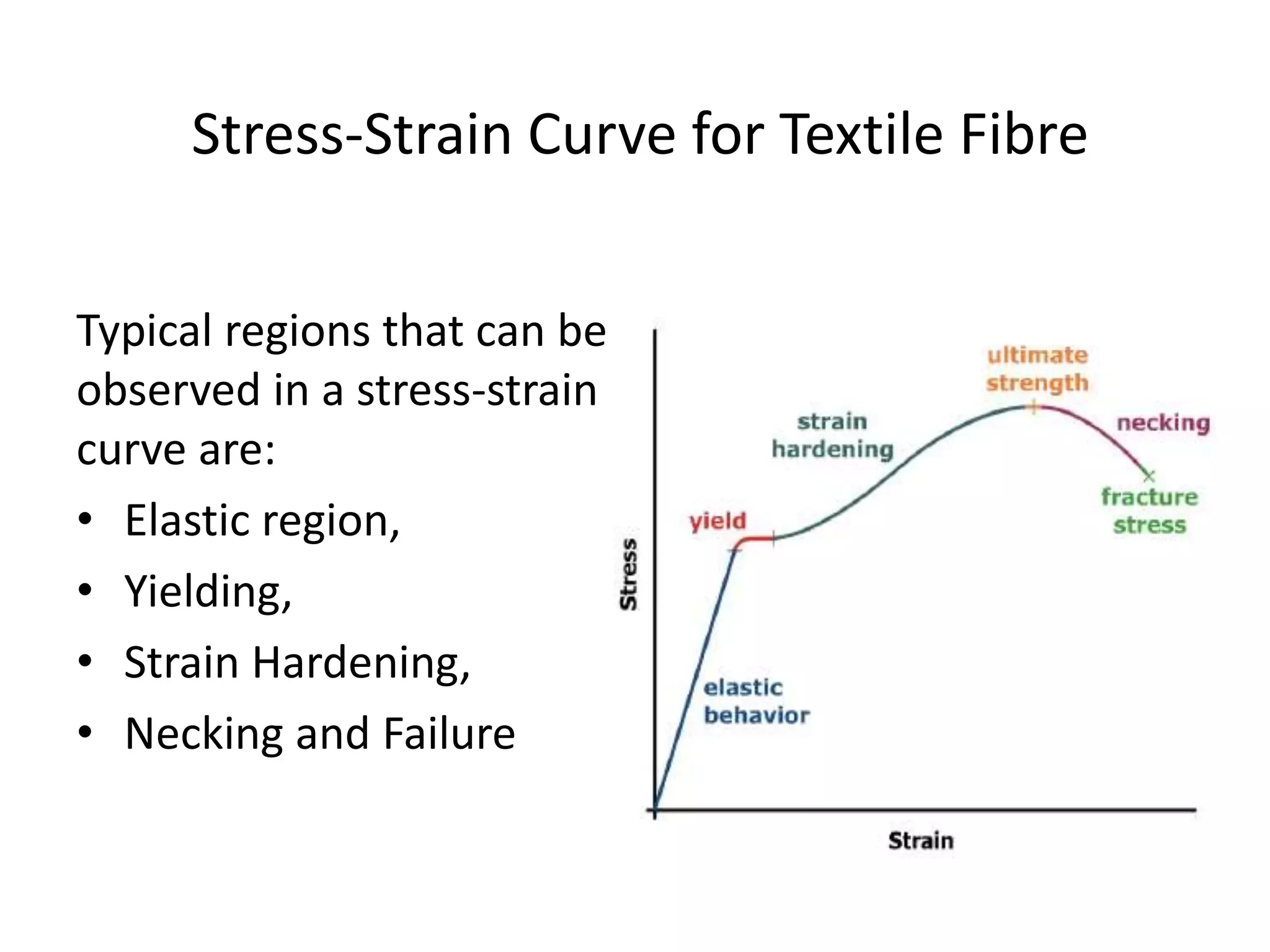

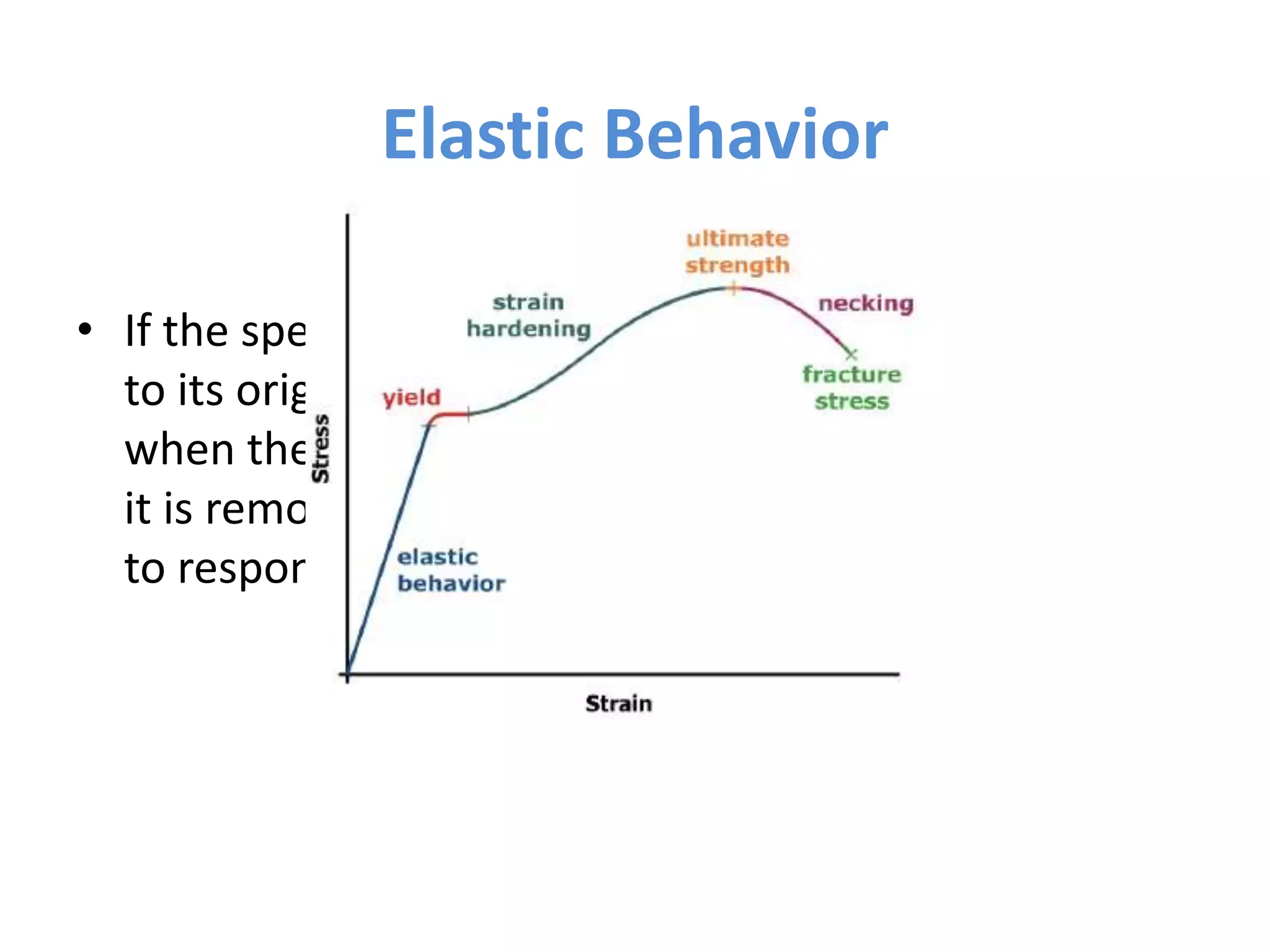

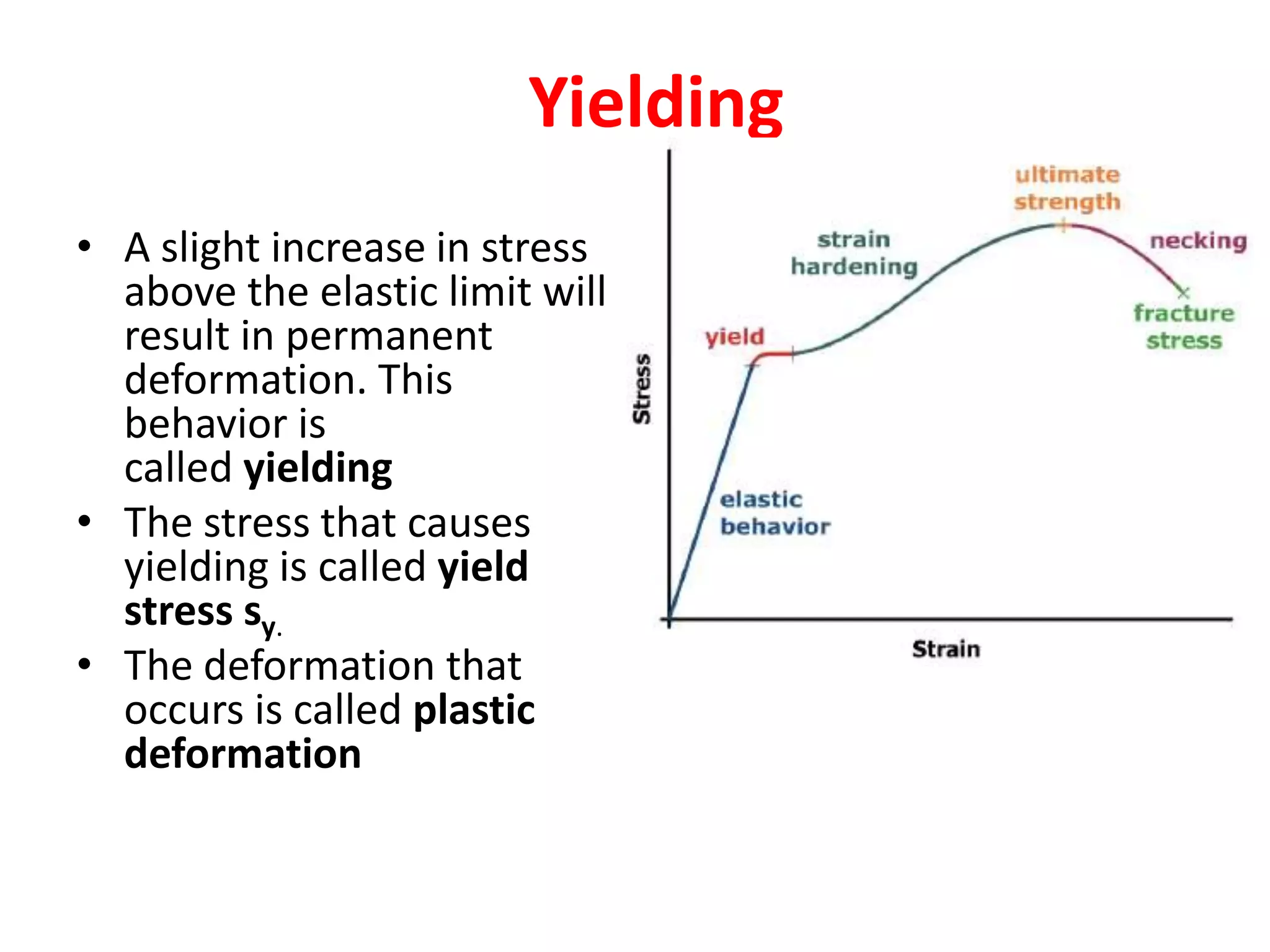

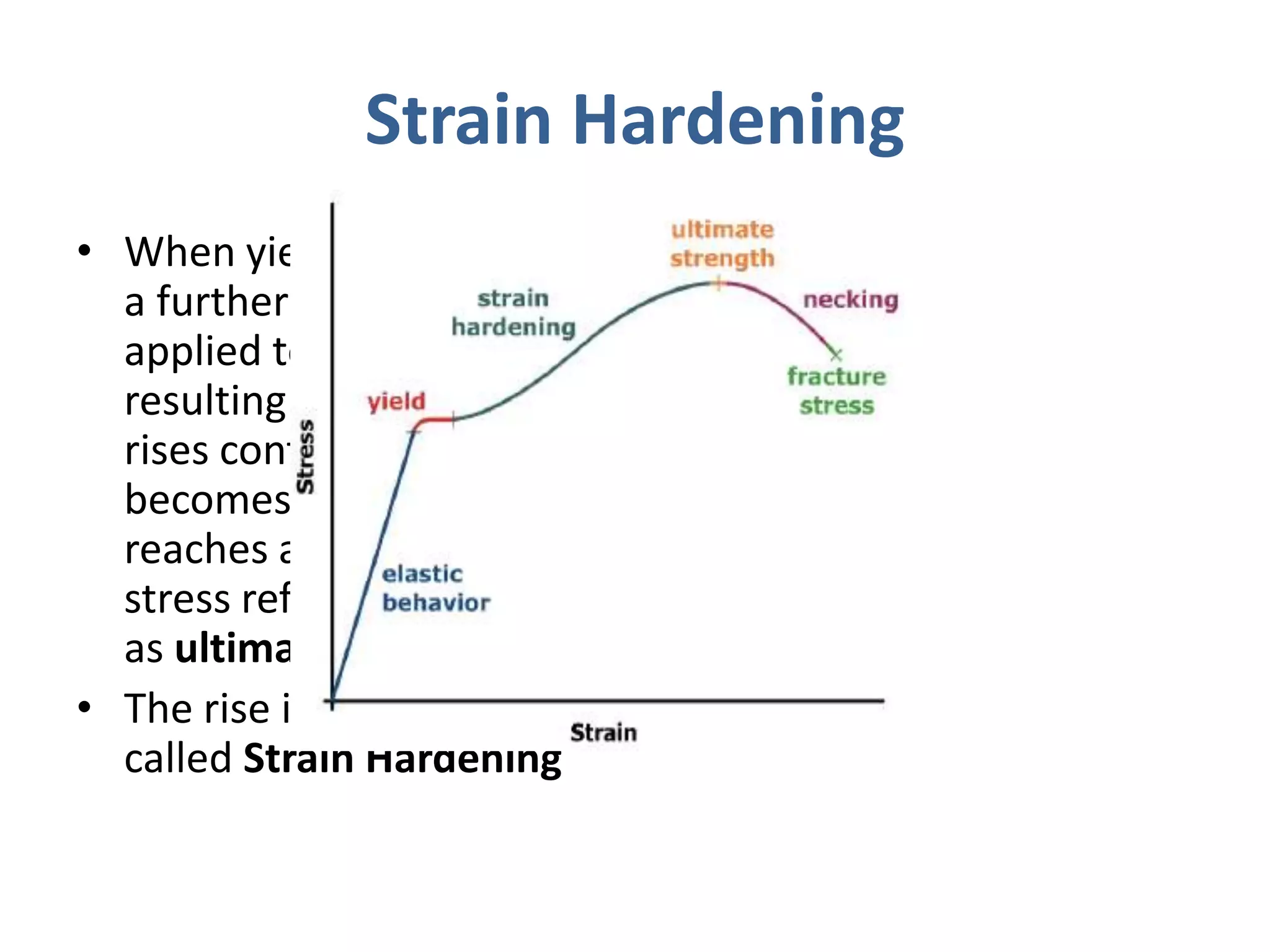

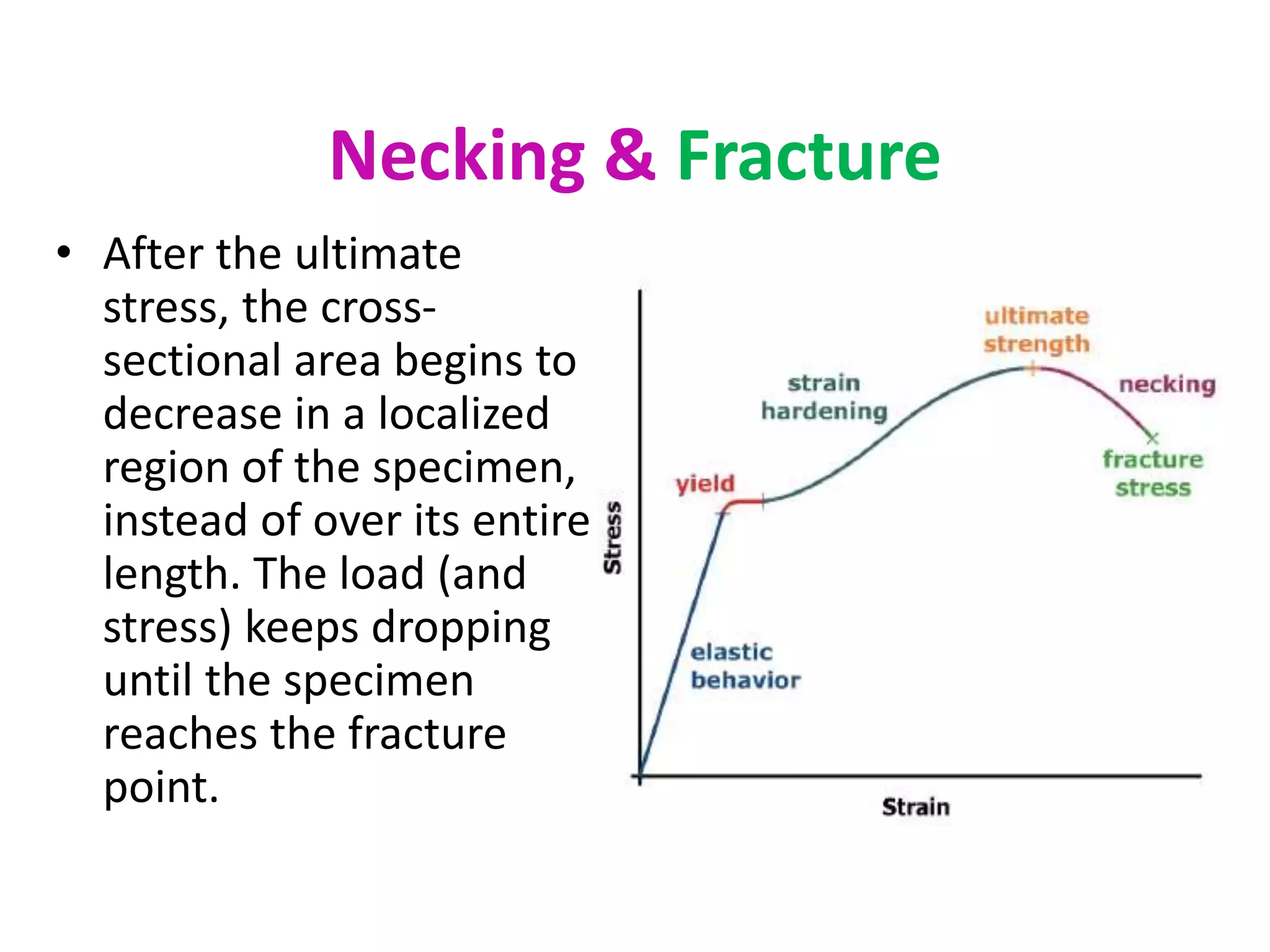

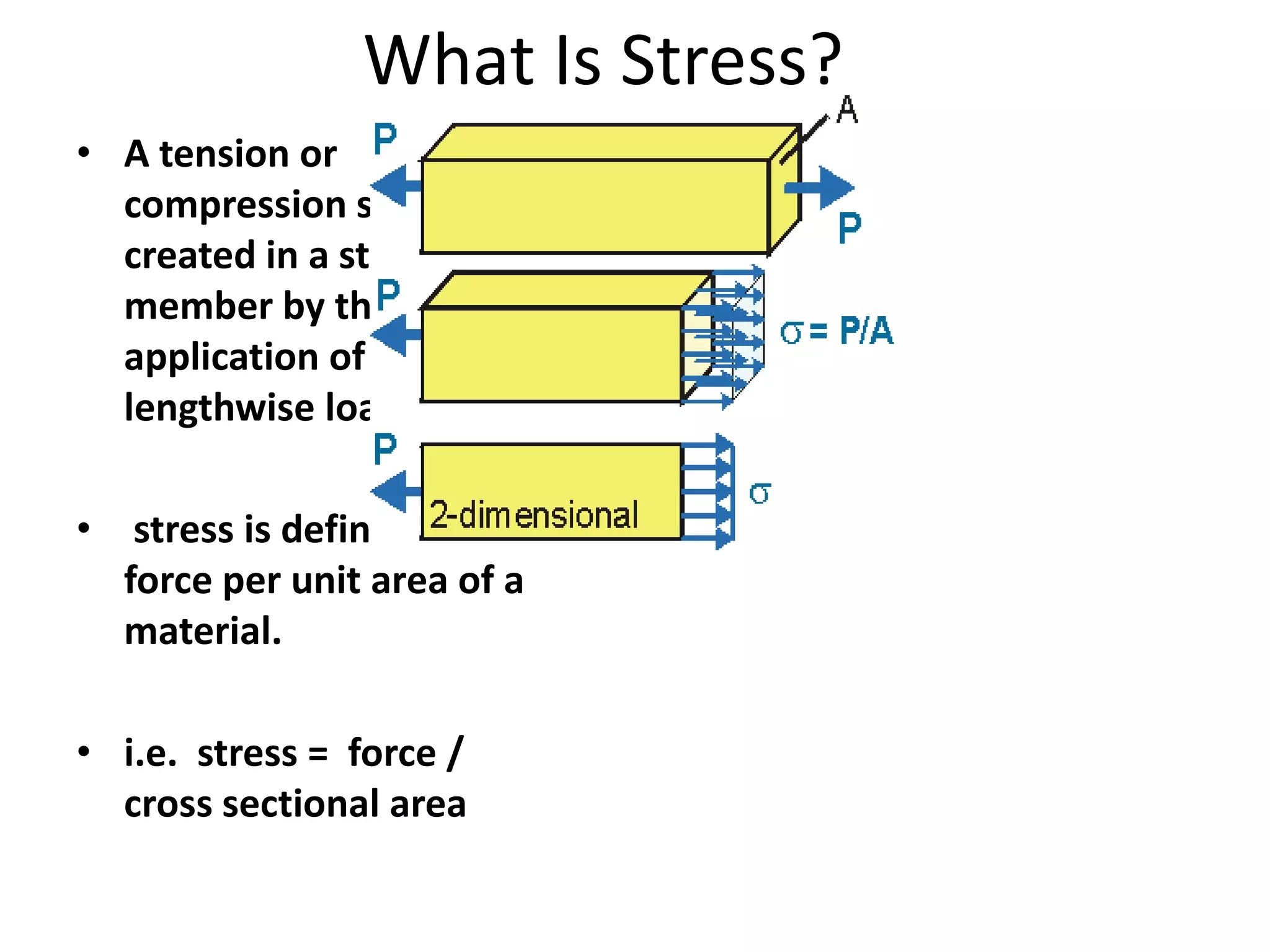

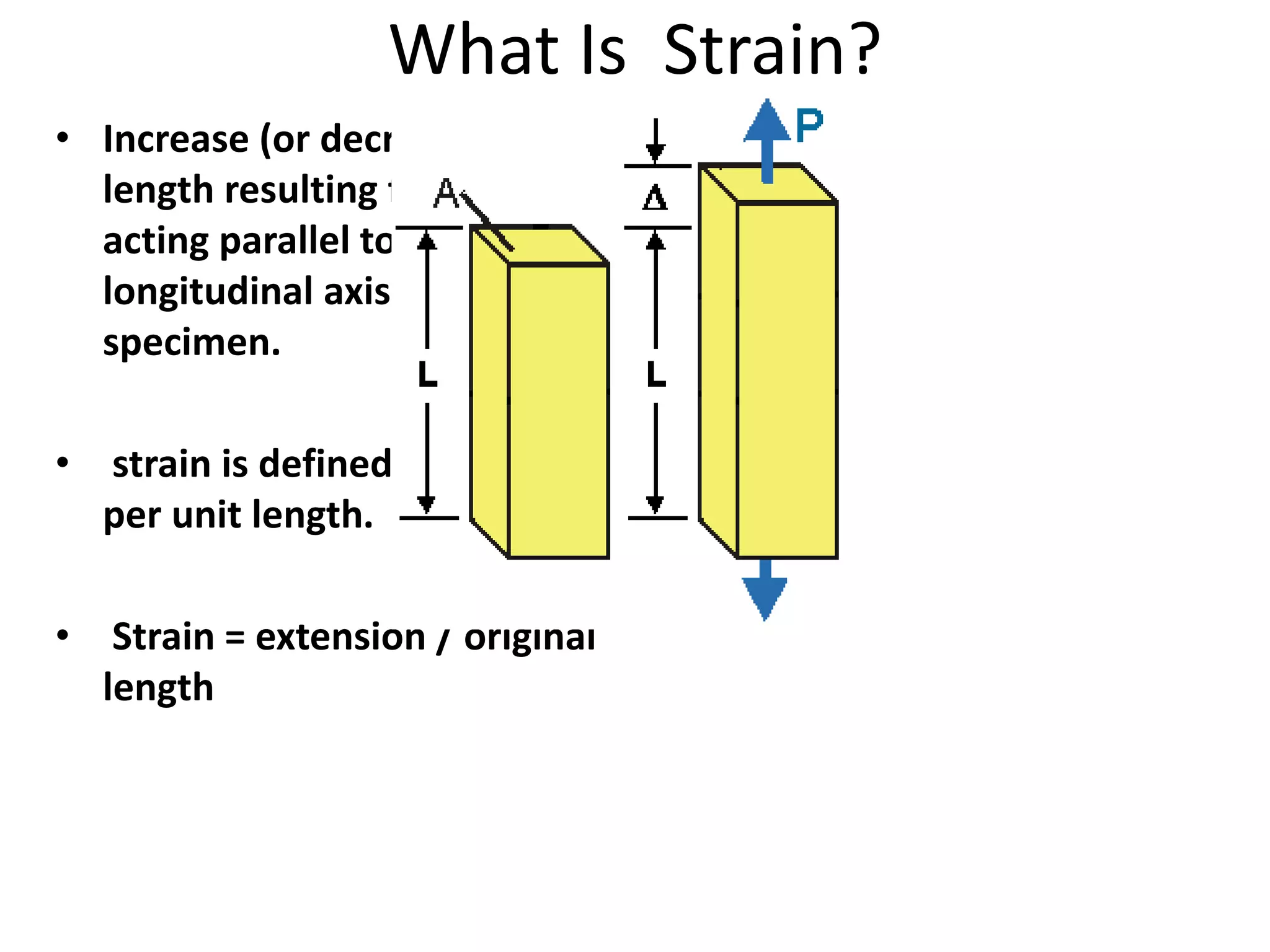

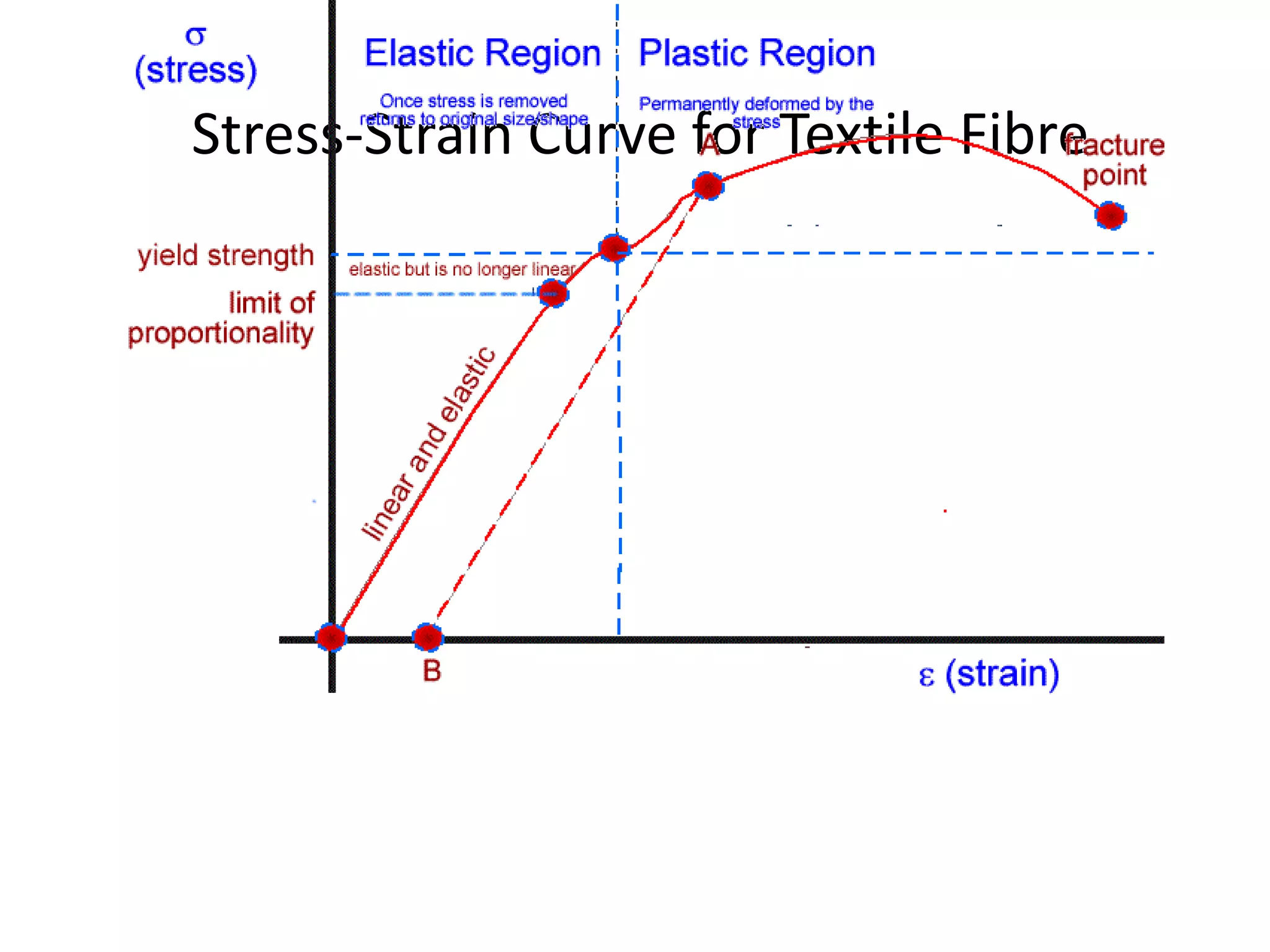

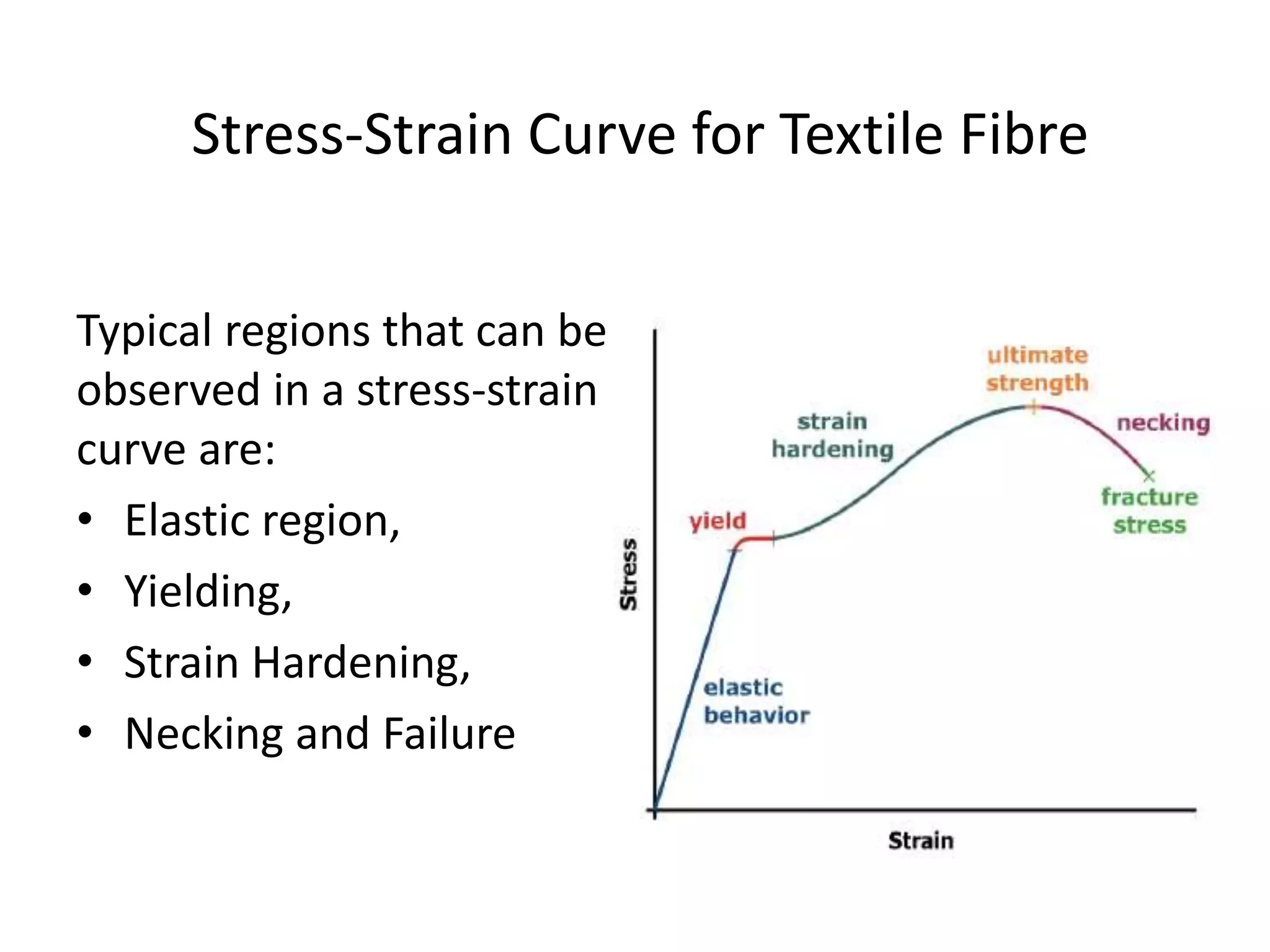

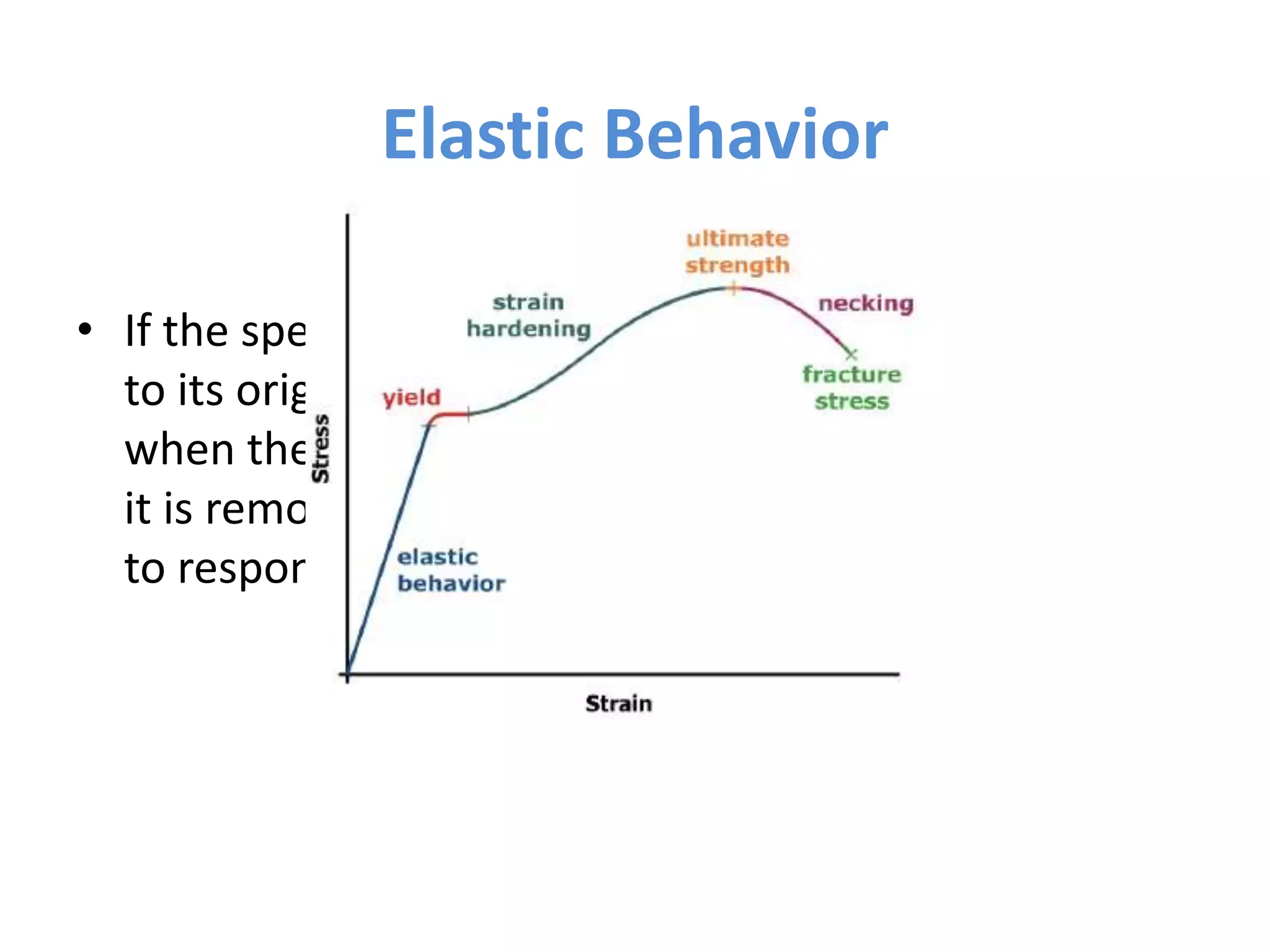

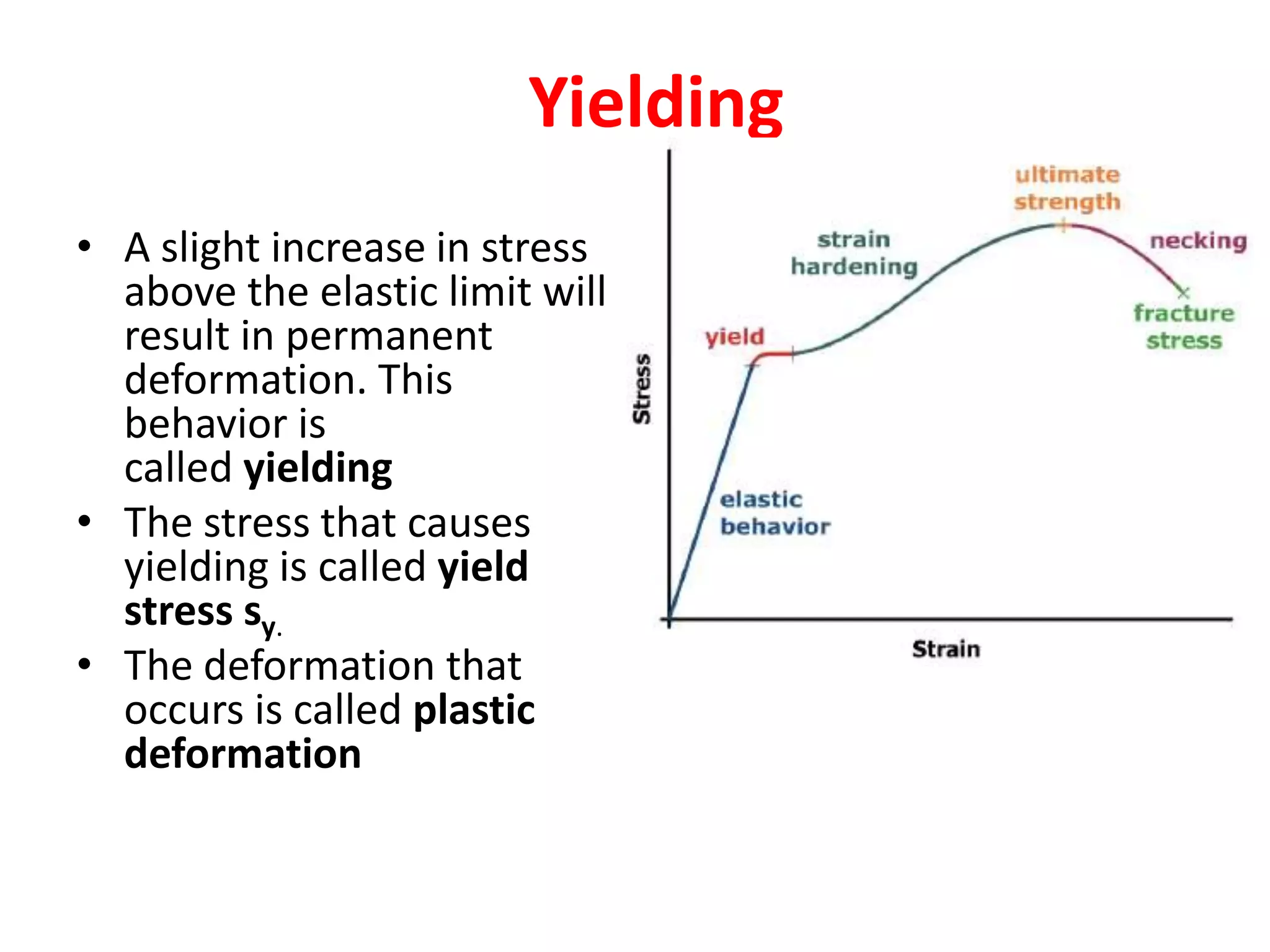

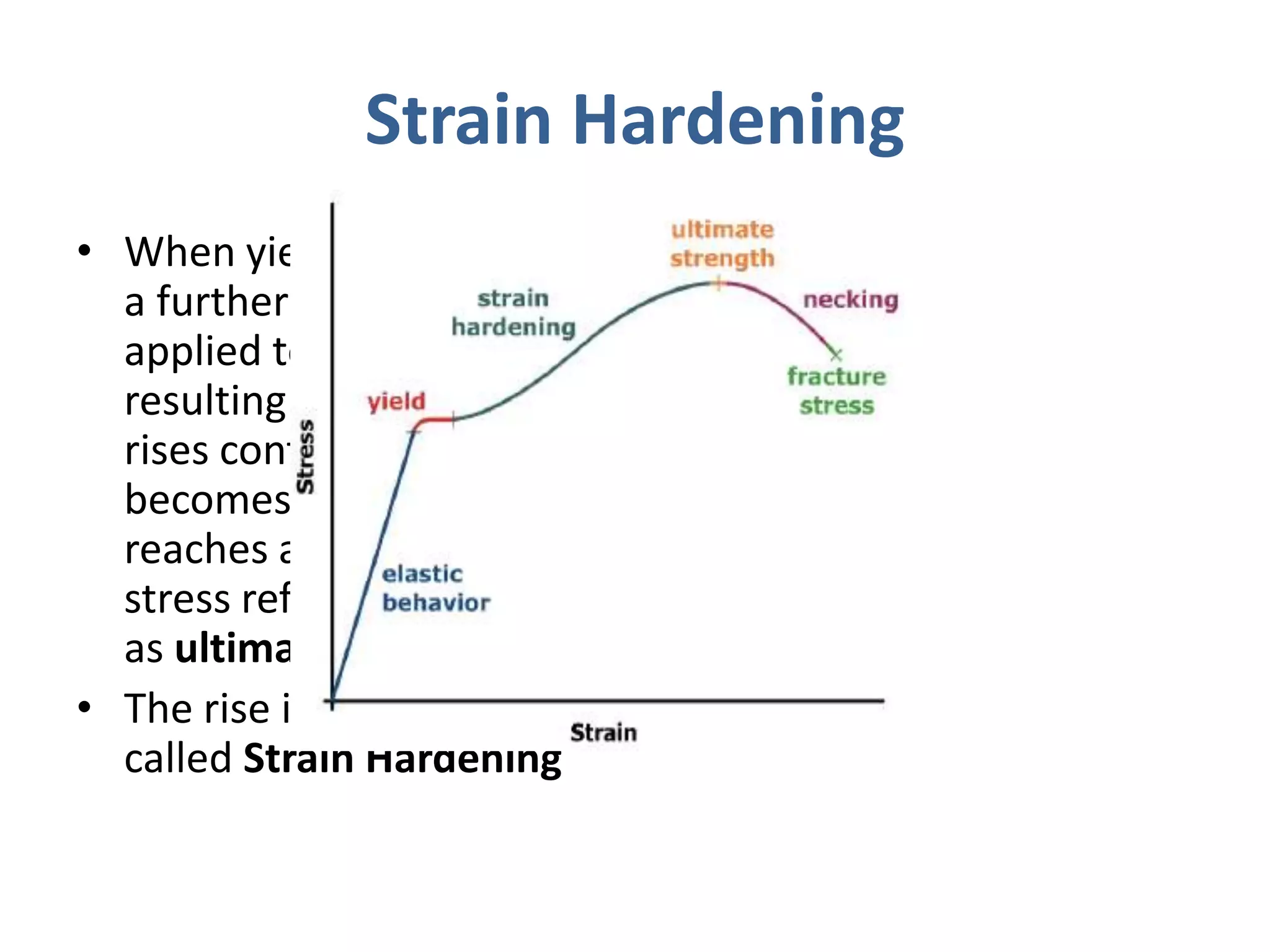

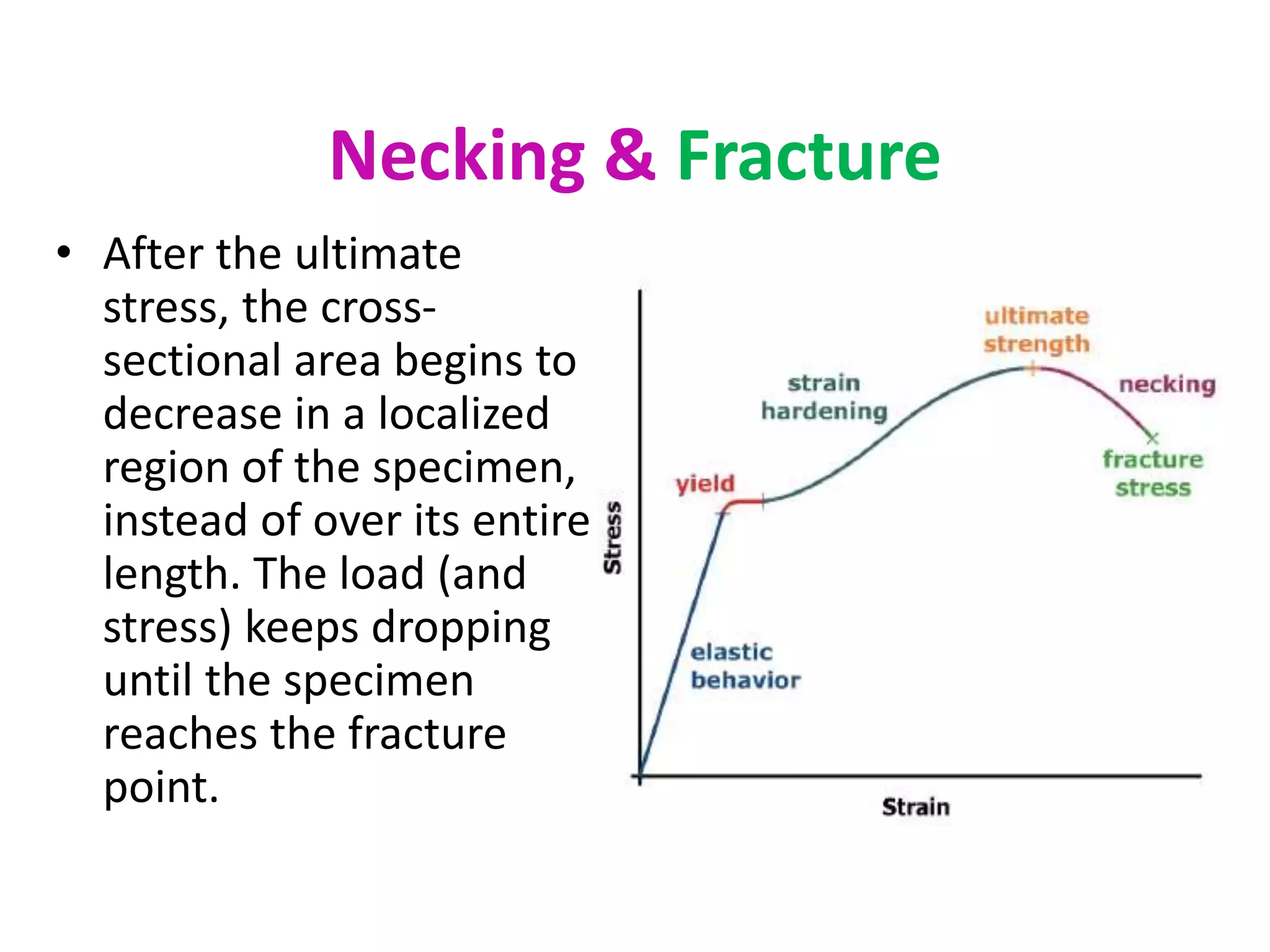

This document discusses the stress-strain curve for textile fibers. It defines stress as the force per unit area applied to a material, and strain as the increase in length from an applied stress. A typical stress-strain curve shows four regions: the elastic region where deformation is recoverable, yielding where permanent deformation begins, strain hardening where the curve rises continuously, and necking and failure where the material fractures.