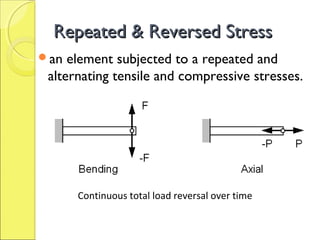

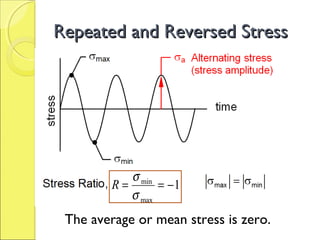

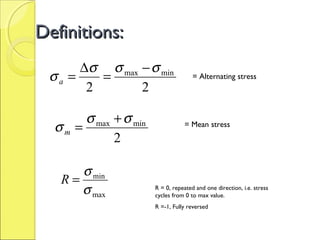

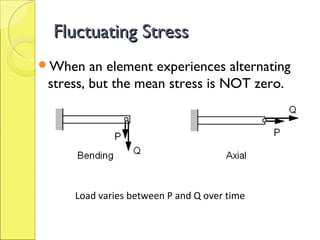

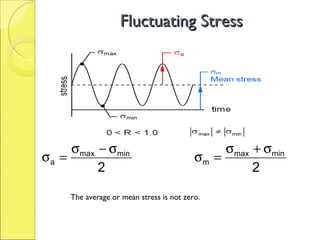

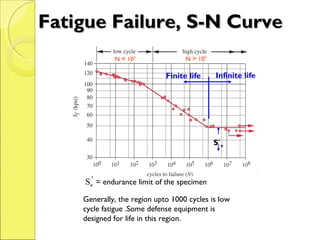

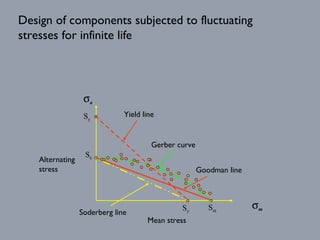

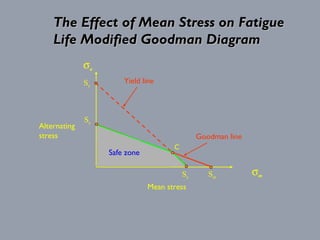

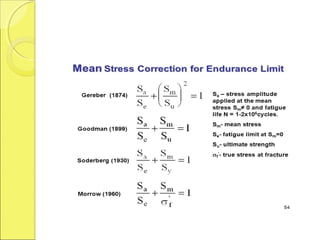

The document discusses the effects of fluctuating stresses on material fatigue in mechanical design, highlighting the differences between cyclic loading and mean stresses. It defines key concepts such as fatigue life, fatigue strength, and endurance limit, providing formulas for calculating these parameters in design applications. Examples illustrate how to determine component dimensions based on fluctuating stress conditions and material properties.

![Example on fluctuating stressExample on fluctuating stress

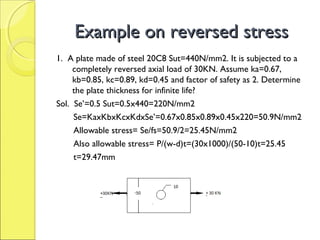

1. A circular rod made of ductile material has endurance strength of

280N/mm2 and ultimate strength of 350N/mm2. The member is

subjected to variable axial load varying from 300KN(tensile) and

70KN(compressive). Assume Ka=0.85, Kb=1.0, Kc=1,Kd=0.55 and

factor of safety as 2. Find suitable diameter of the rod?

Sol. Se’=280N/mm2

Sut=350N/mm2

Using Goodman line equation:

Sm/Sut + Sa/Se=1/fs……………………(1)

Se=KaxKbxKcxKcxKdxSe’=0.85x1x1x0.55x280=132.3MPa

Sm=(Pmax+Pmin)/2A=[300+(-70)]/2A=115/A N/mm2

Sa=(Pmax-Pmin)/2A=[300-(-70)]/2A=185/A N/mm2

Put values in eqn. 1 we get: A= 3456mm2

Now A= π/4 d2=3456 or d=66.3mm](https://image.slidesharecdn.com/metalfatigueppt-170113123938/85/Metal-fatigue-ppt-22-320.jpg)