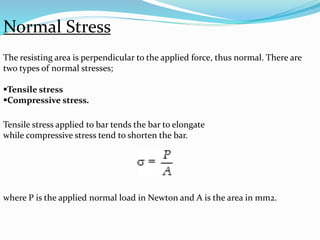

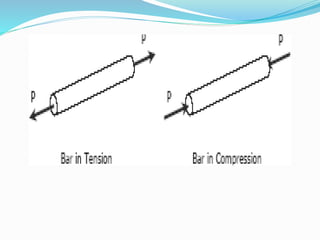

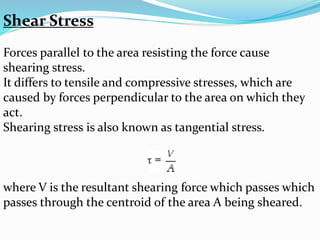

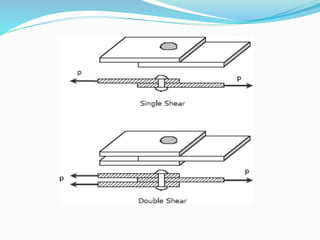

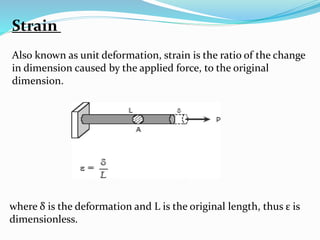

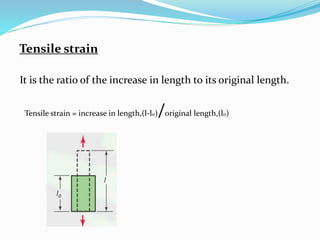

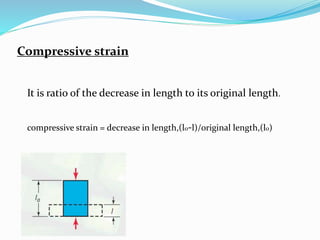

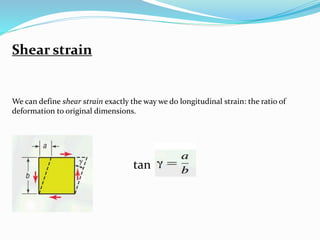

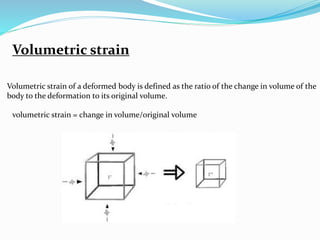

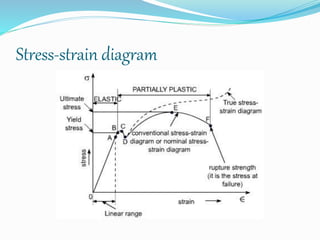

The document discusses different types of stresses and strains experienced by materials. It defines normal stress as stress perpendicular to the resisting area, with tensile and compressive stresses elongating and shortening materials. Combined stress includes shear and torsional stresses from parallel forces. Strain is defined as the change in dimension due to an applied force. The stress-strain diagram is then explained, showing the material's behavior from the proportional limit through yielding and strain hardening until ultimate failure. Key points on the curve include the proportionality limit, elastic limit, yield points, and ultimate stress.