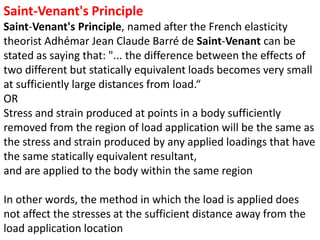

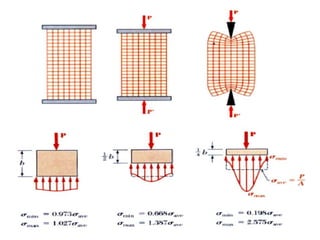

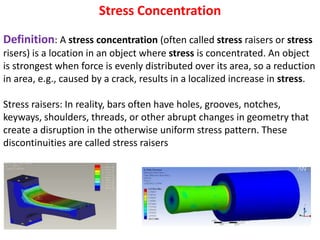

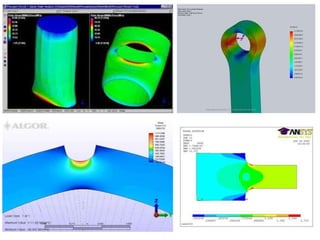

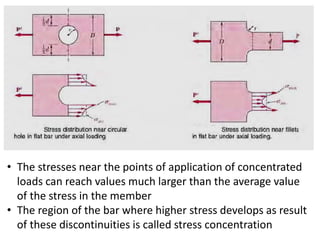

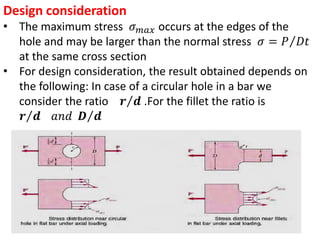

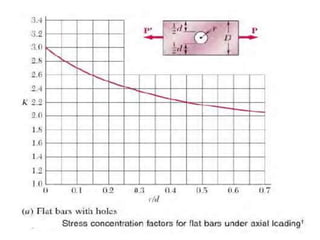

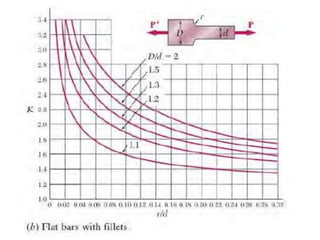

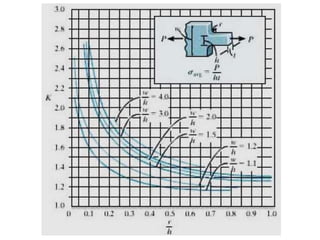

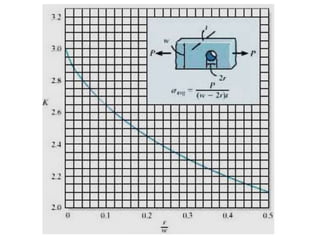

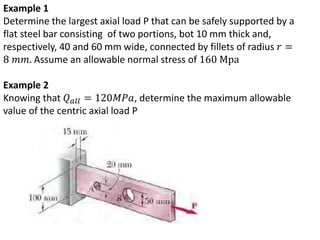

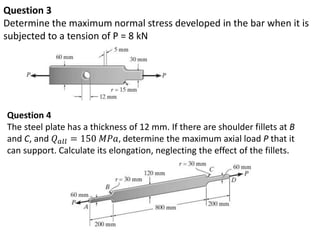

Saint-Venant's principle states that the stresses and strains far away from the load application point are unaffected by the exact nature of the load or its application method, but only depend on the resultant load magnitude and application area. Stress concentrations occur where the cross-sectional area changes abruptly, like holes, notches, or threads, and cause local stress values much higher than the average stress. The stress concentration factor K is used to relate the maximum stress σmax to the average stress σave in a cross-section. Design engineers use stress concentration factors and allowable stress values to determine if a given load will exceed the material's strength at stress concentration locations.