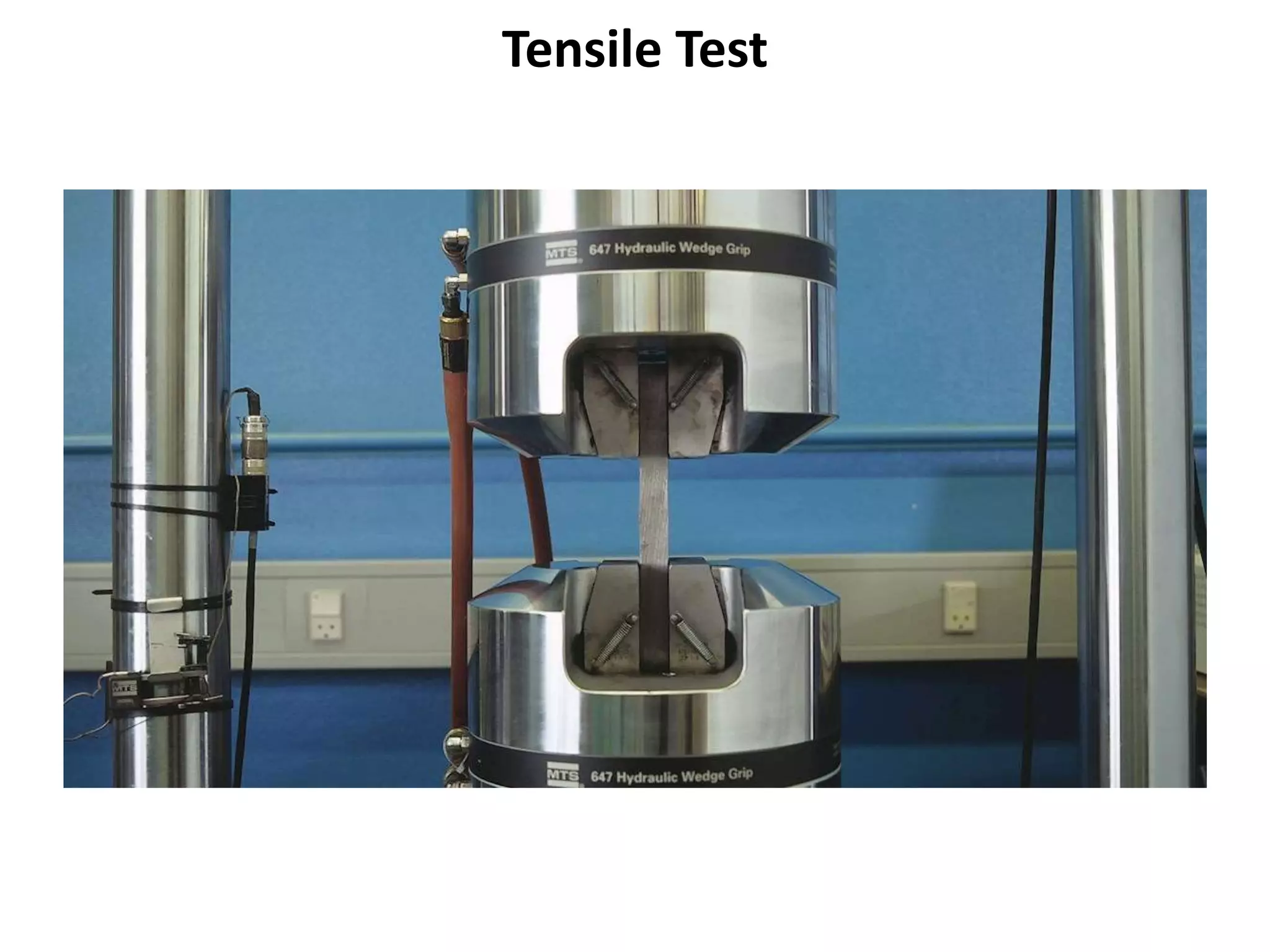

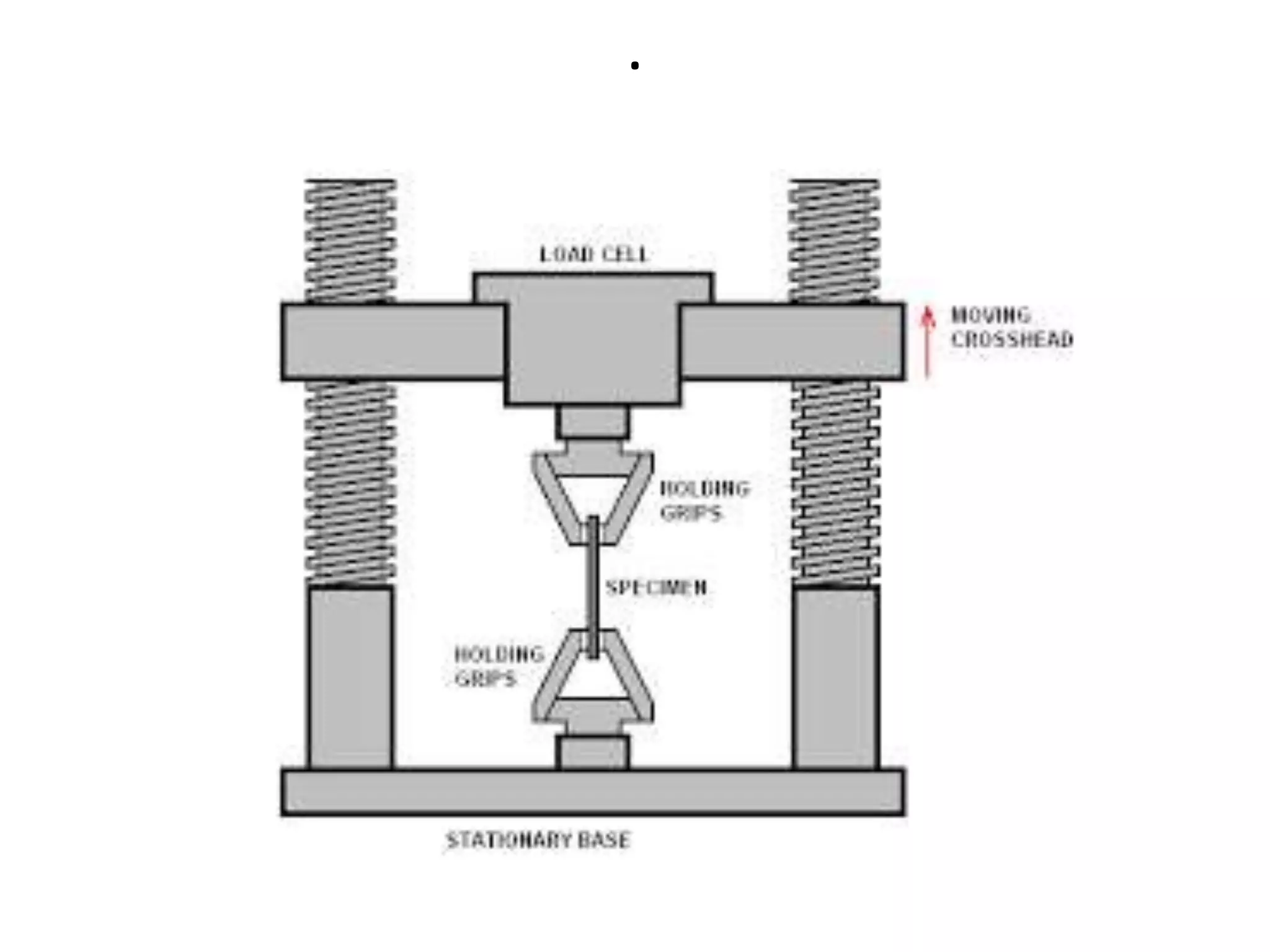

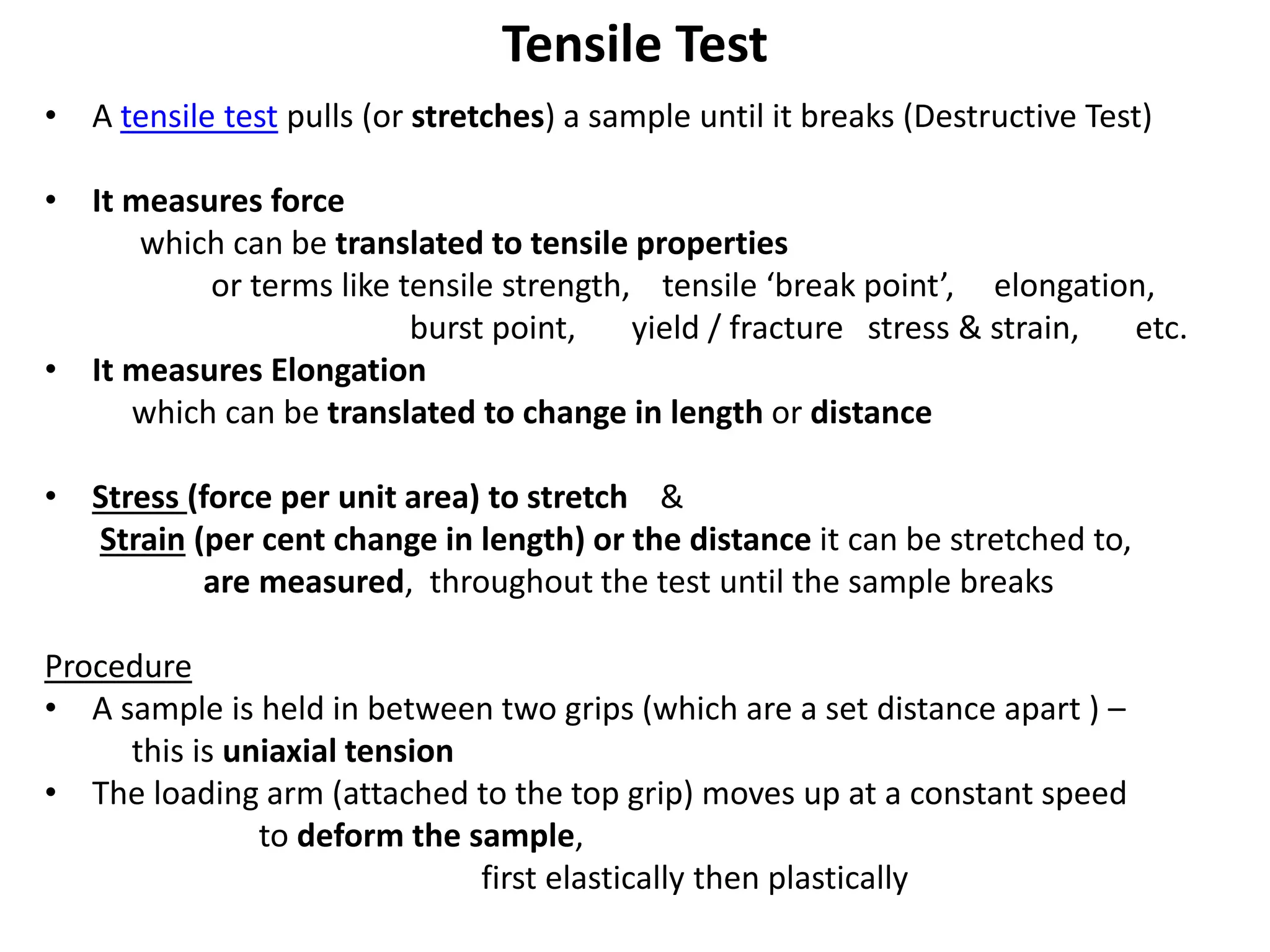

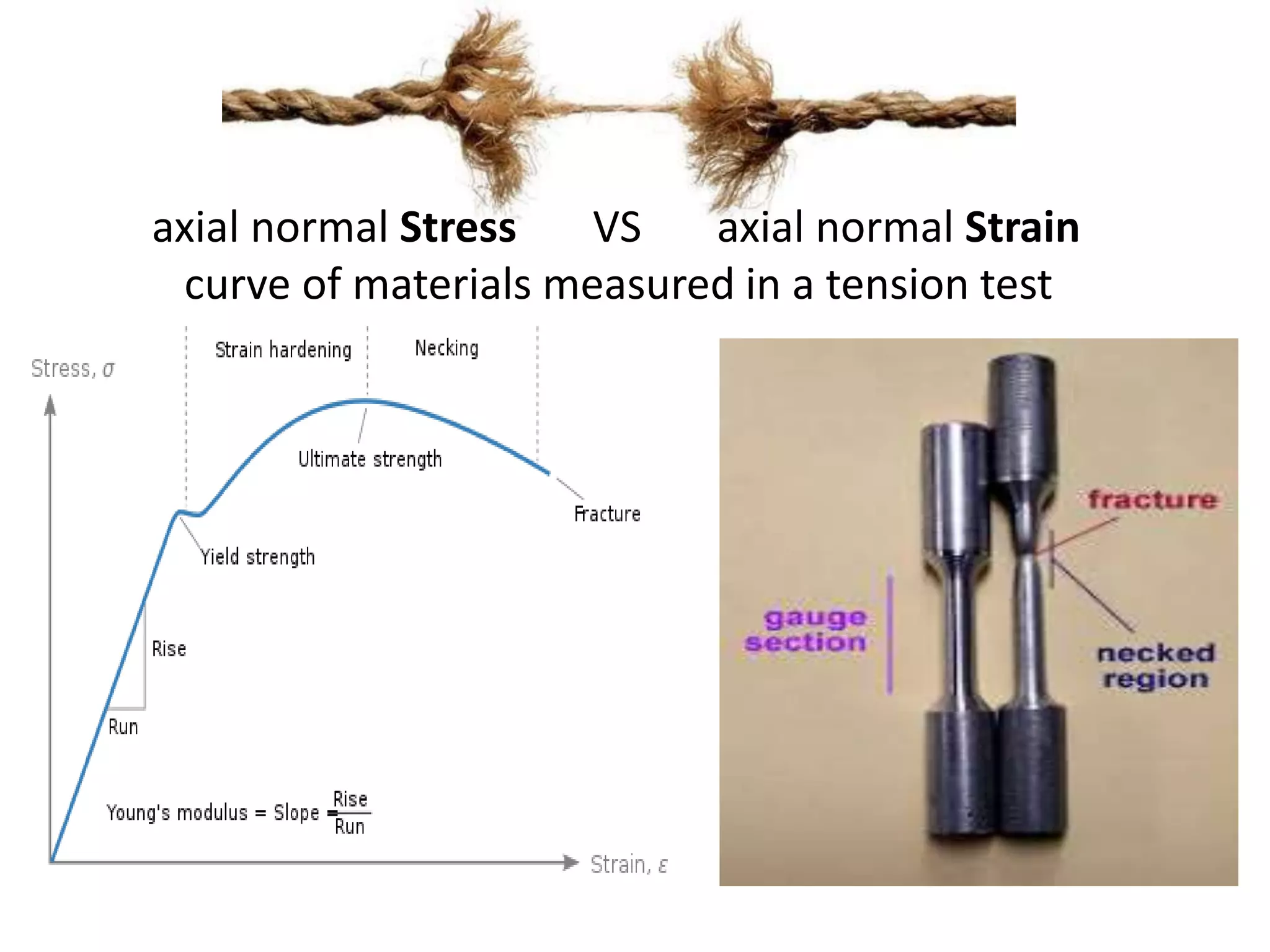

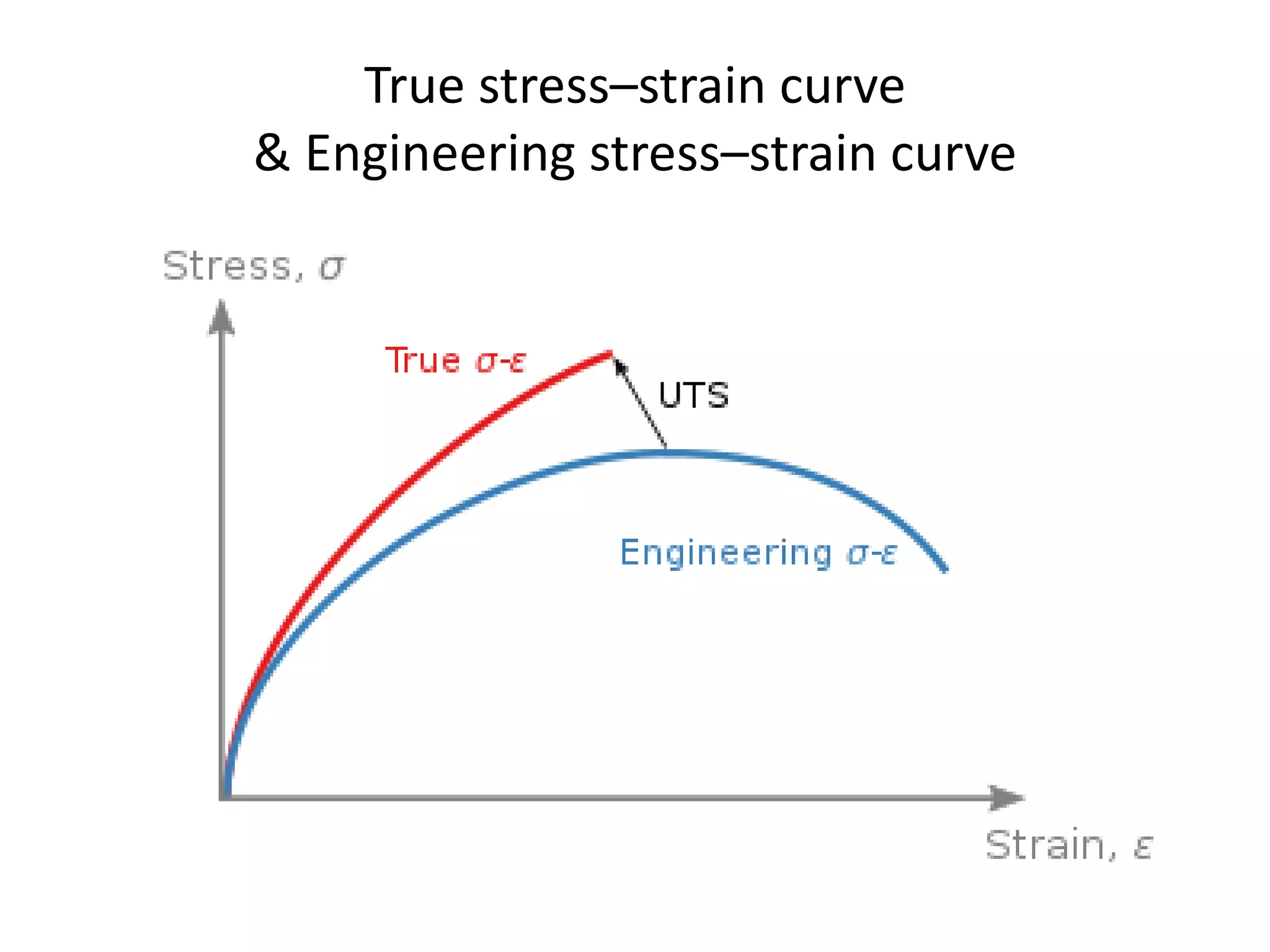

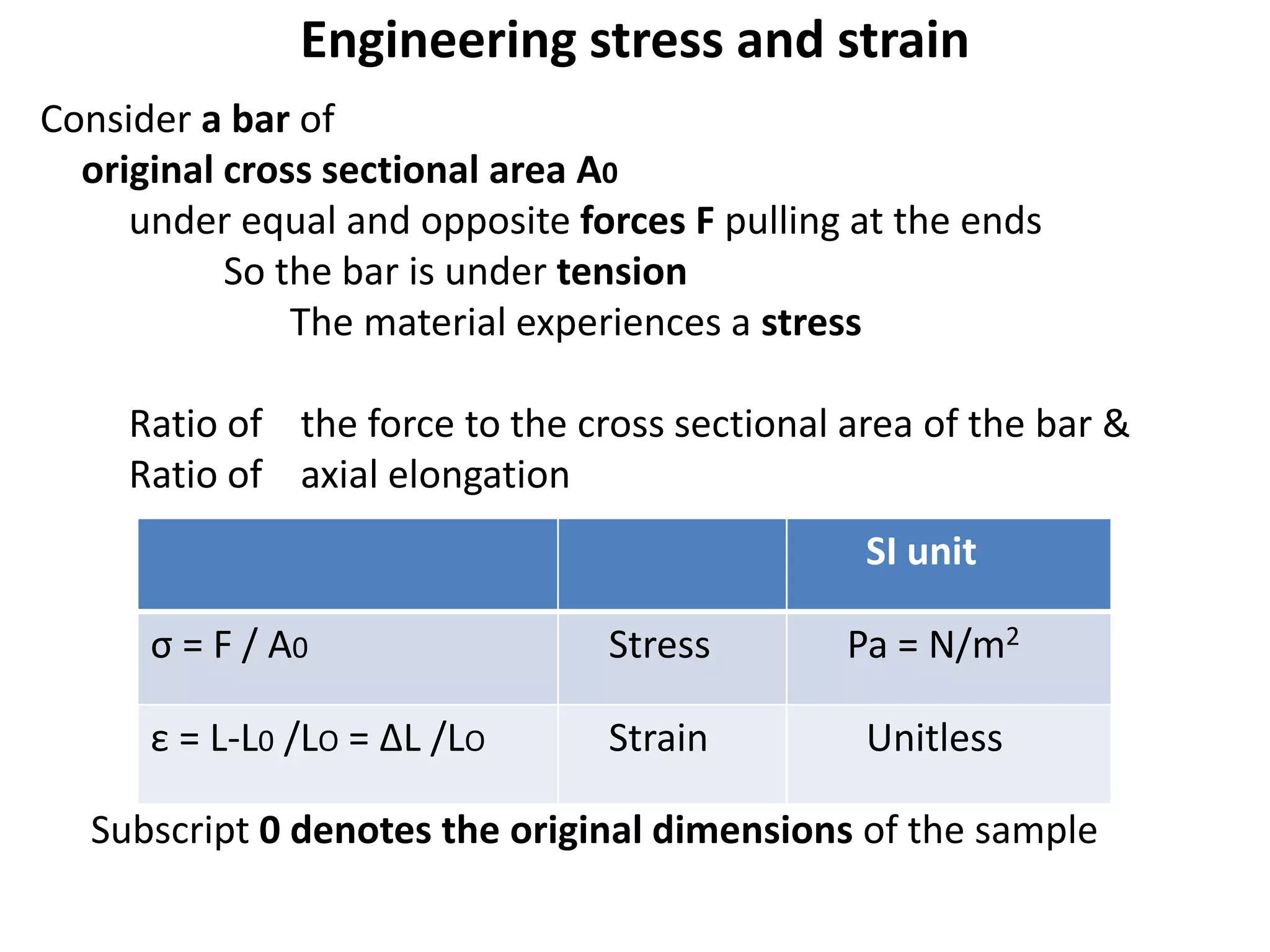

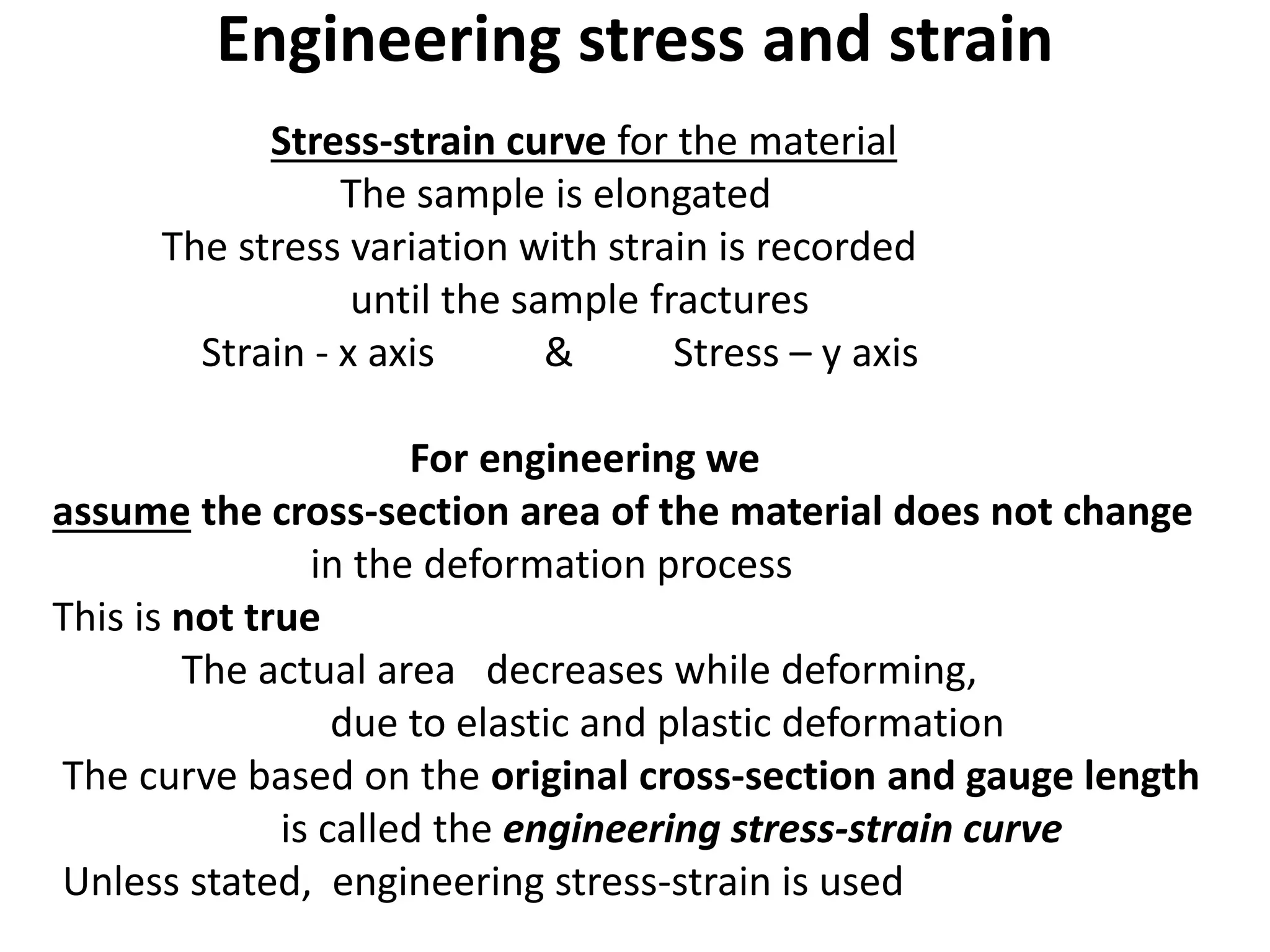

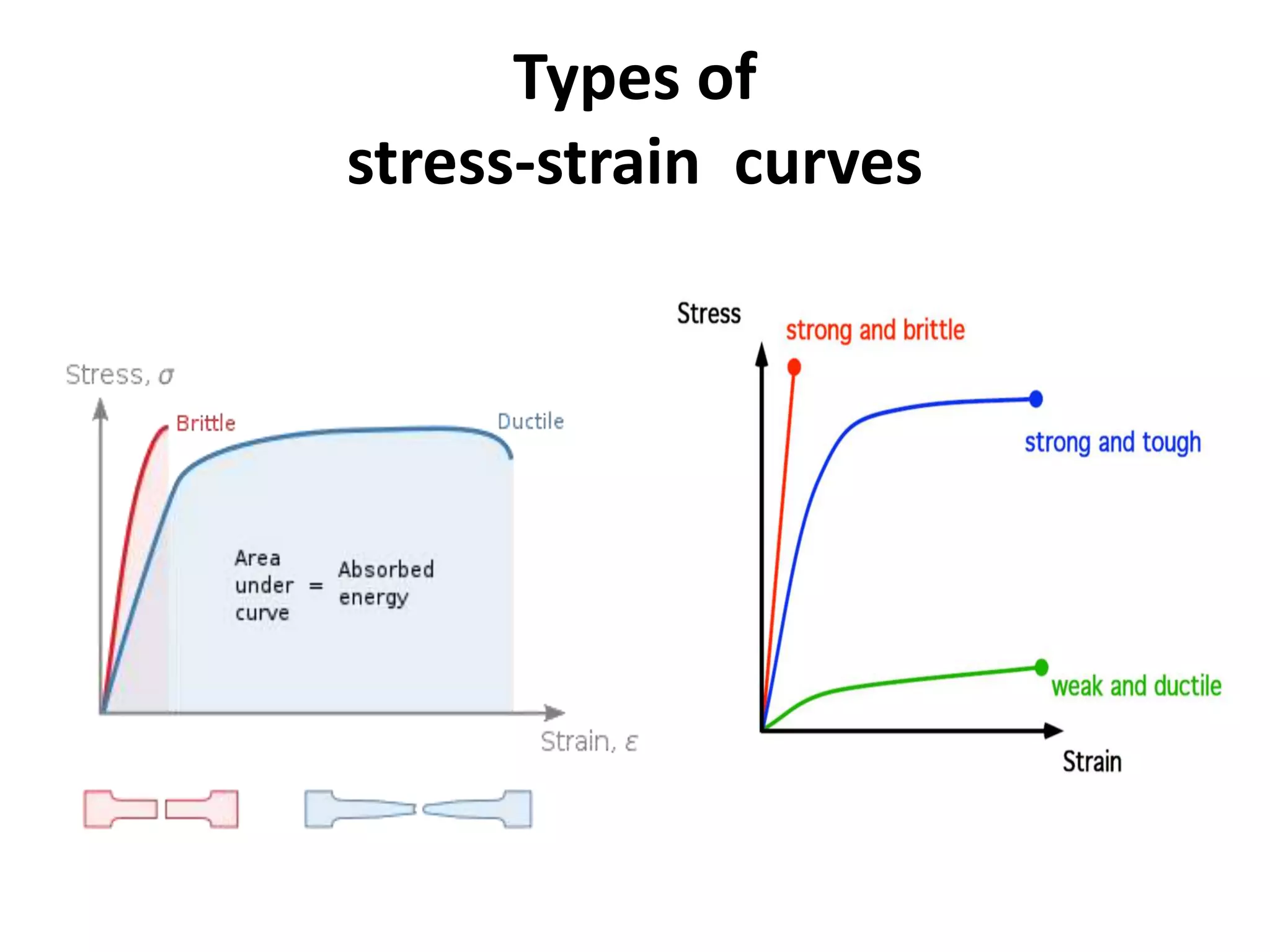

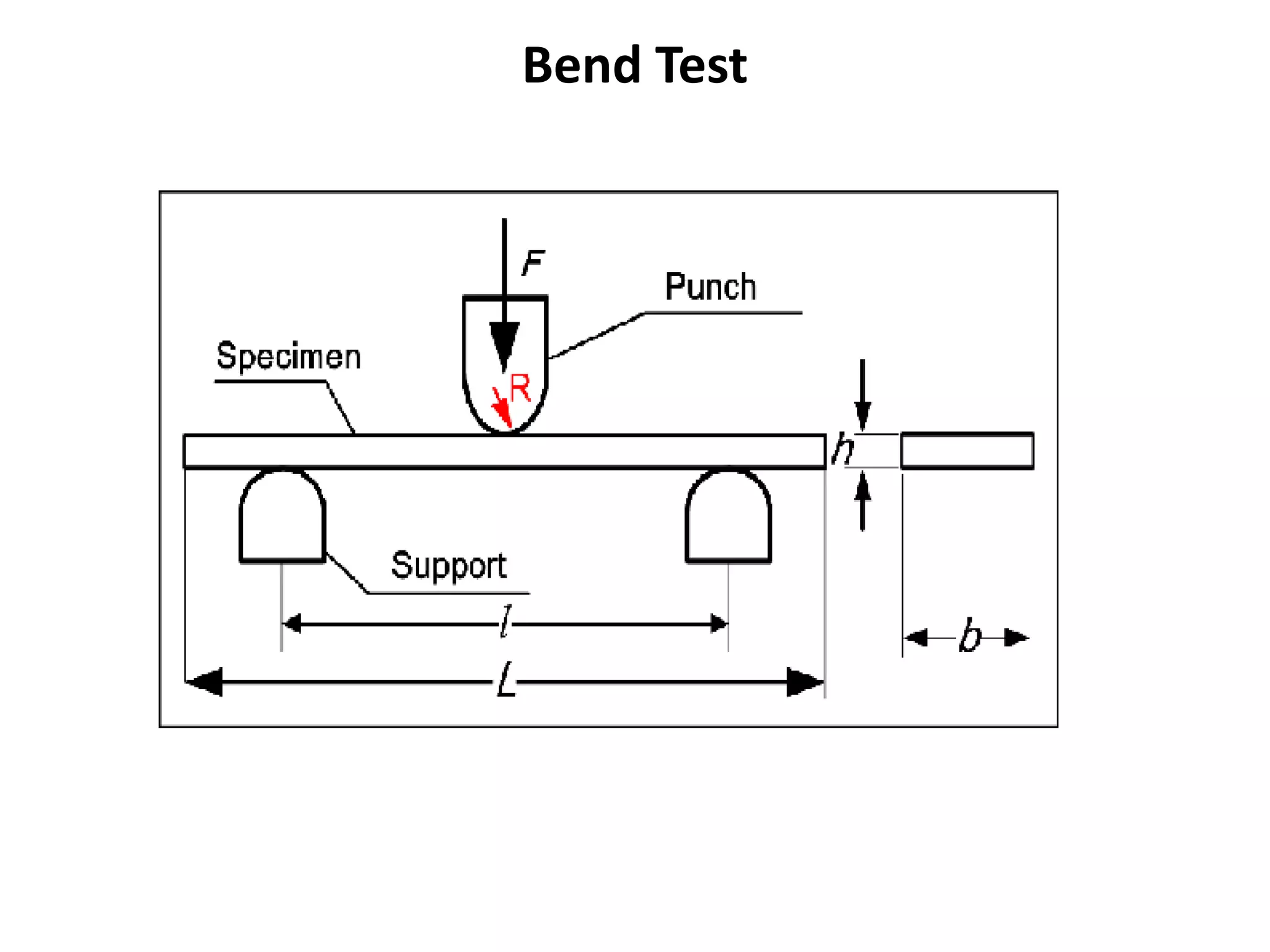

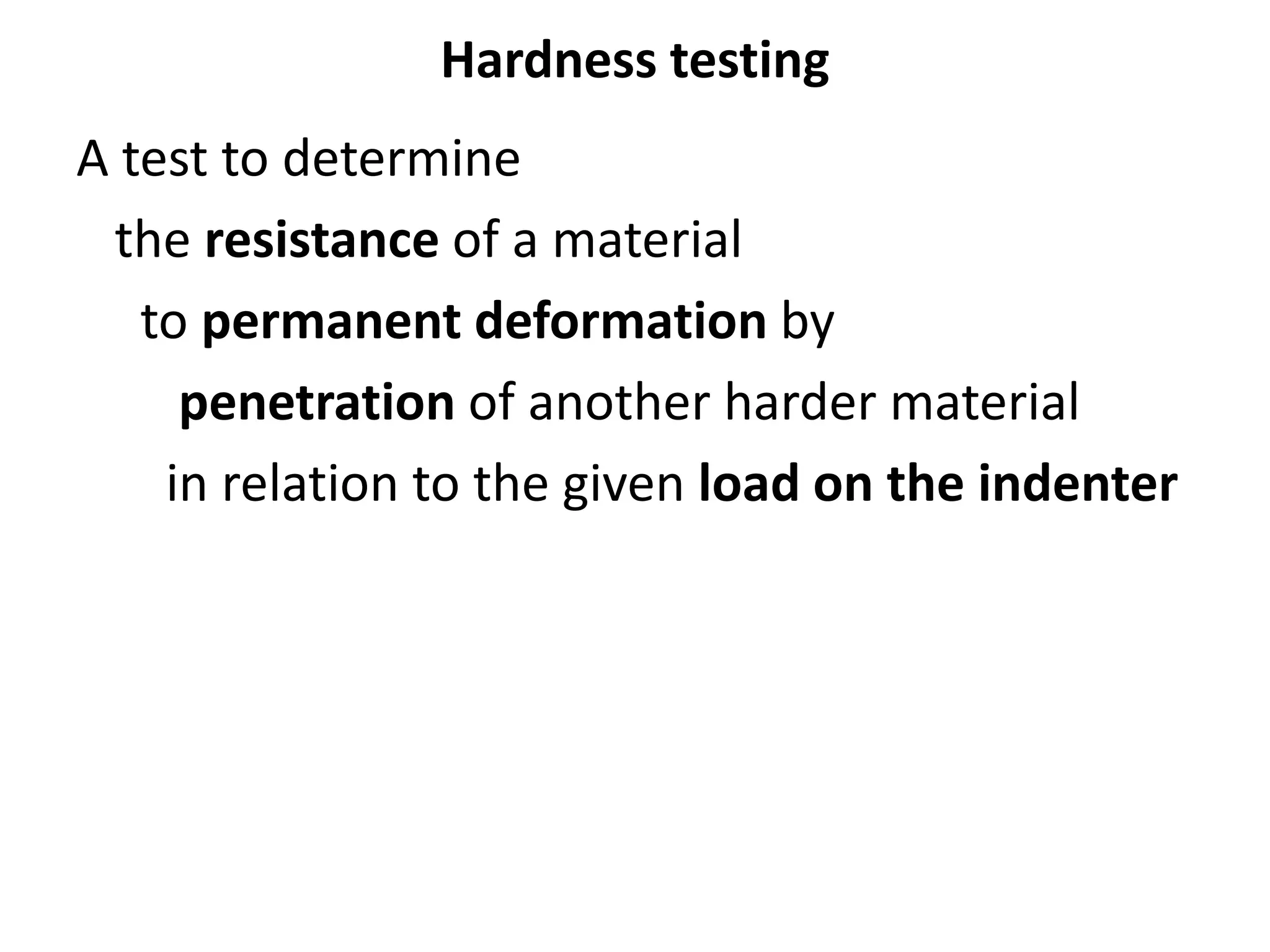

A tensile test involves applying tension to a sample until failure to determine its mechanical properties. A sample is held in grips and pulled at a constant rate, measuring the stress and strain as it elongates elastically and plastically. The stress-strain curve produced provides information on properties like tensile strength, elastic modulus, and ductility. Other common tests include compression, bending, torsion, and hardness tests, each providing data on how materials respond to different types of forces.

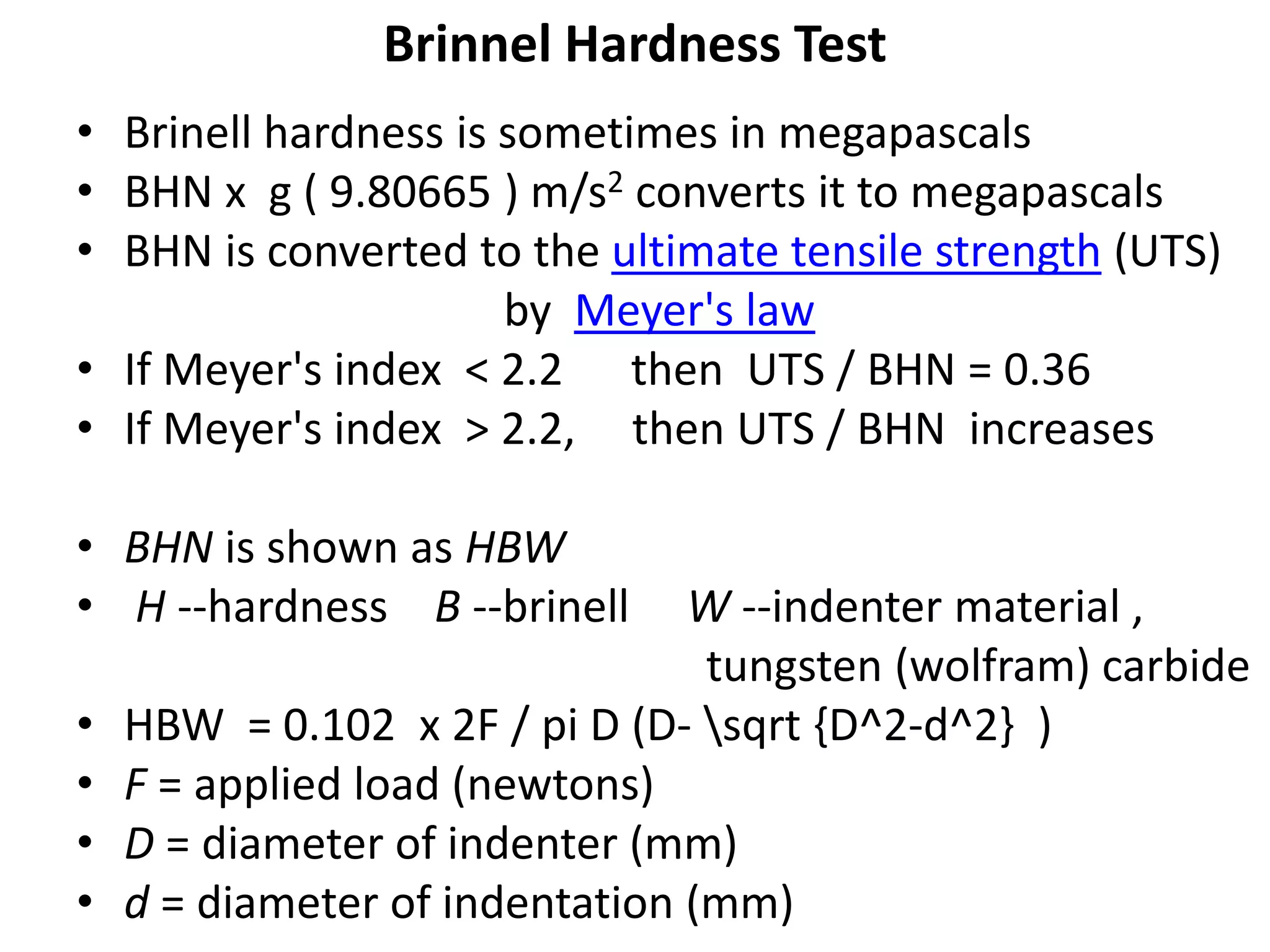

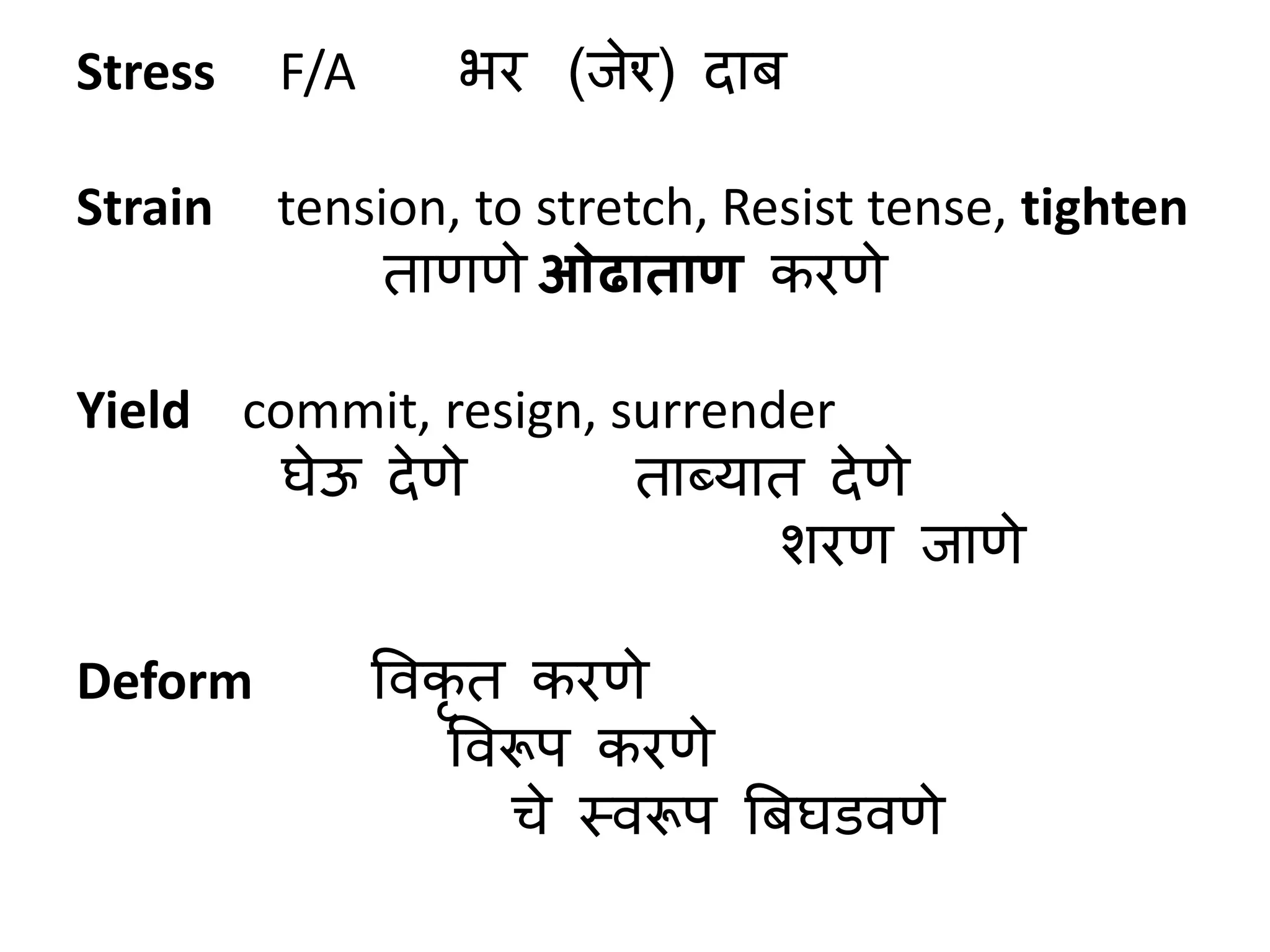

![Brinnel Hardness Test

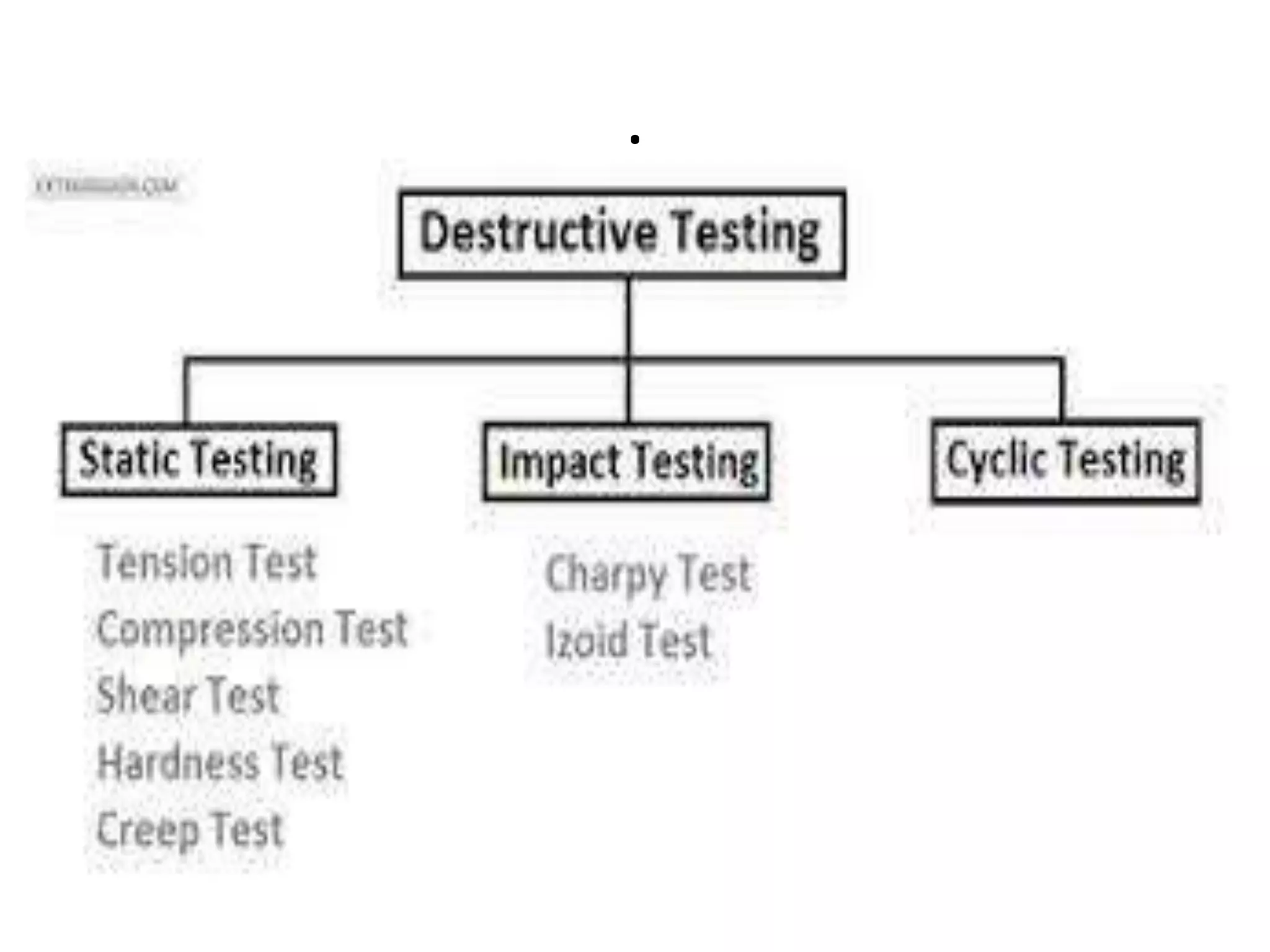

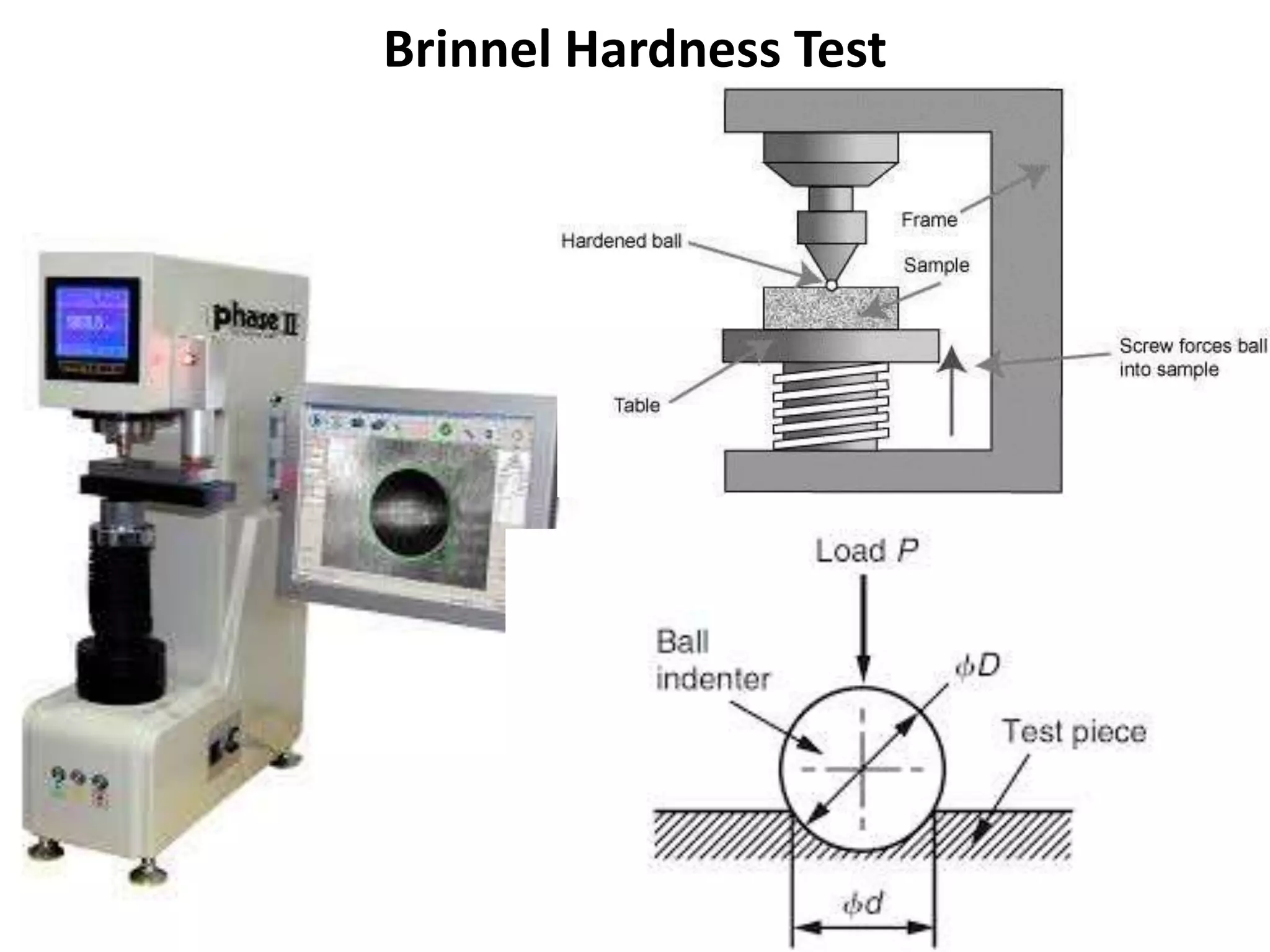

• For softer materials,

• 10 mm diameter steel ball as an indenter is used

• A smaller force 3,000 kgf (29.42 kN) is used

• For harder materials

• A tungsten carbide ball indenter is used

• The indentation is measured & hardness calculated as:

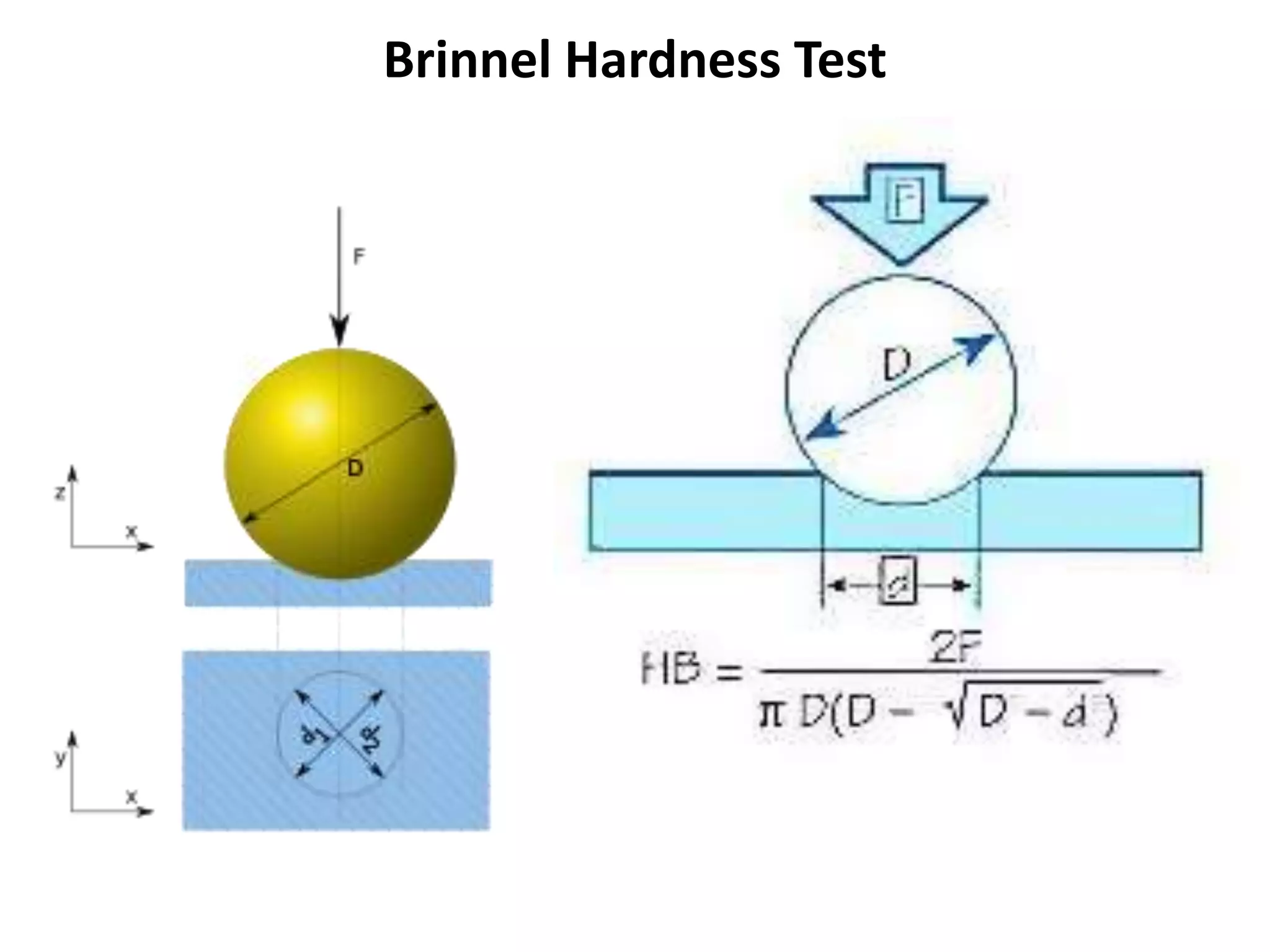

BHN = 2P / pi D [ D- sqrt {D^2 - d^2} ]

• BHN = Brinell Hardness Number (kgf/mm2)

• P = applied load in kilogram-force (kgf)

• D = diameter of indenter (mm)

• d = diameter of indentation (mm)](https://image.slidesharecdn.com/u2mechanicalpropertiestheirtesting-210925070650/75/U2-mechanicalproperties-amp-theirtesting-50-2048.jpg)