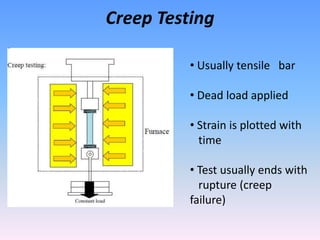

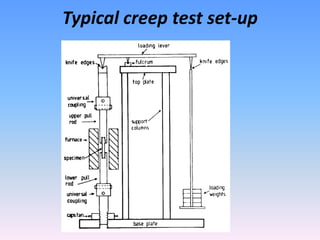

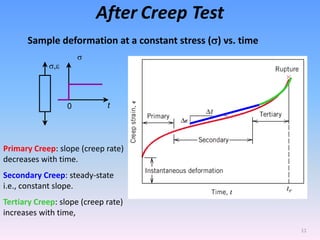

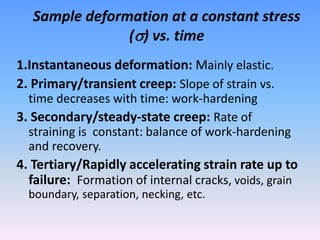

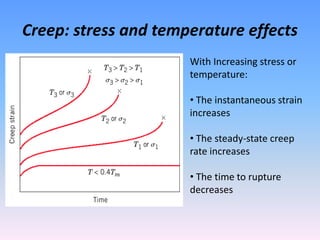

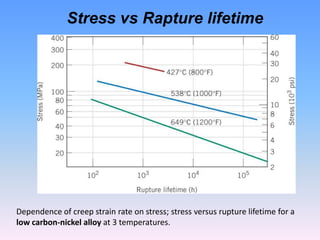

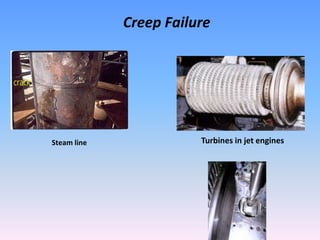

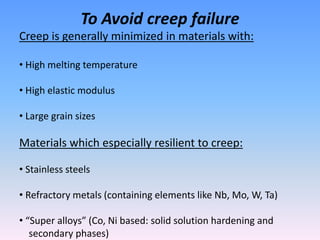

Creep is the time-dependent deformation of a material under constant stress at high temperatures. It occurs due to the movement of vacancies and dislocations within a material's microstructure. The critical temperature for creep to occur is 40% of the material's melting temperature. Different creep mechanisms dominate depending on the material, stress levels, and temperatures. Creep testing involves applying a constant load to a sample and measuring the strain over time until failure. The three stages of creep are primary, secondary, and tertiary creep. Creep can lead to failure of components in applications like turbines and nuclear reactors where high stresses and temperatures are present.