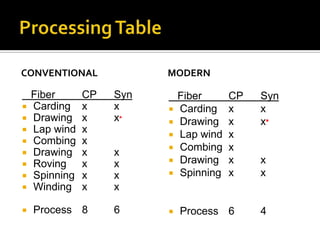

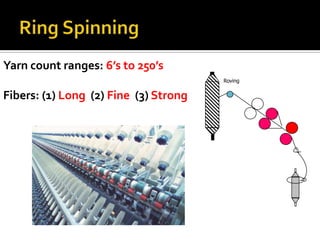

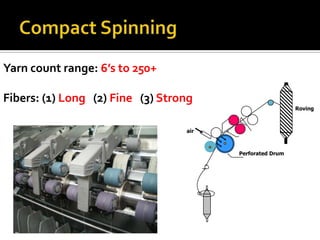

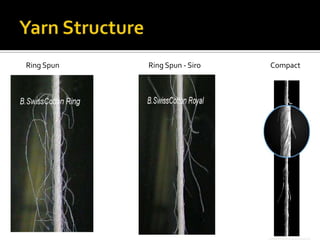

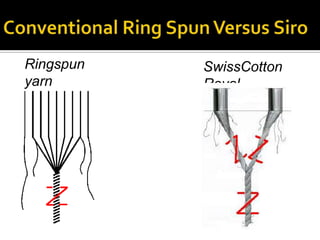

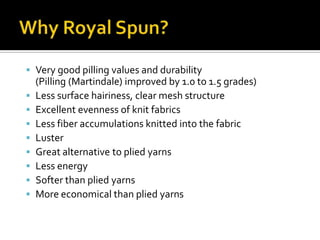

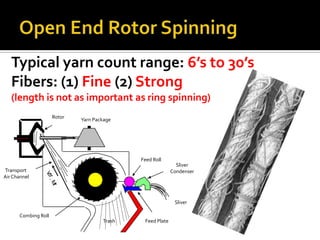

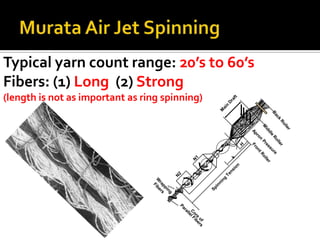

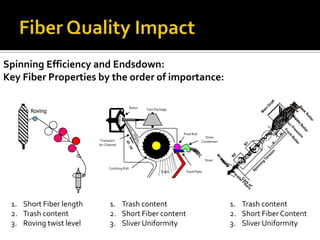

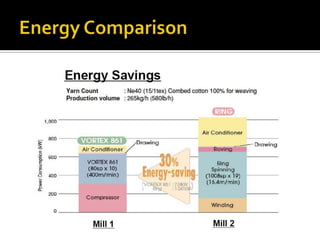

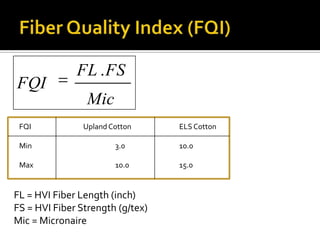

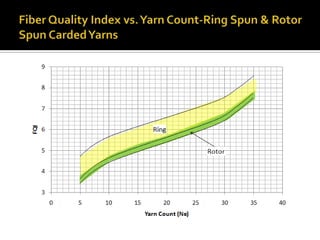

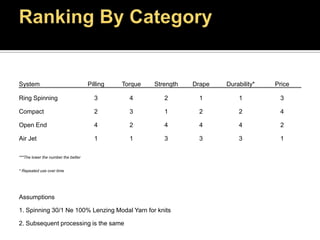

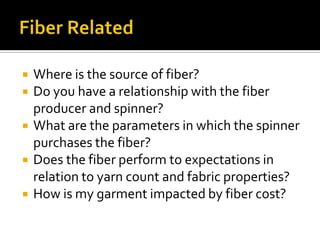

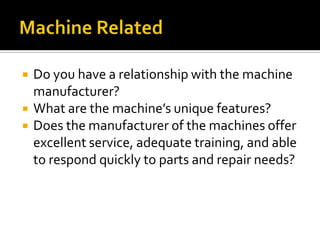

This document discusses different types of spinning systems used to process staple fibers into yarns. It describes the main types as ring spinning, compact spinning, open end spinning, and air jet spinning. For each type, it provides information on the typical yarn count ranges, fiber properties required, and basic processing steps. It also compares the production efficiency and quality differences between conventional and modern spinning systems. Finally, it discusses important factors to consider regarding fiber quality and its impact on yarn quality and production costs.