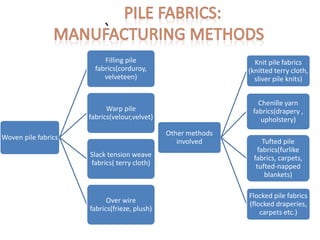

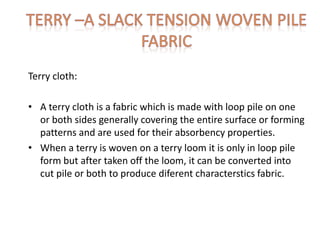

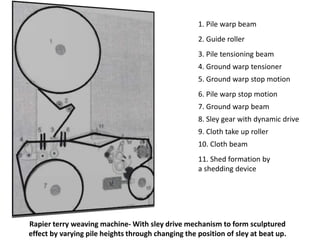

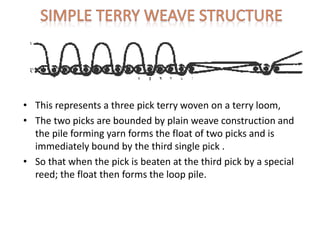

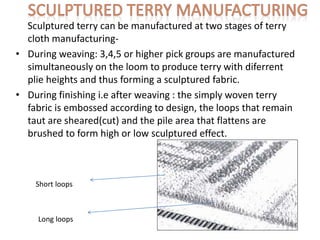

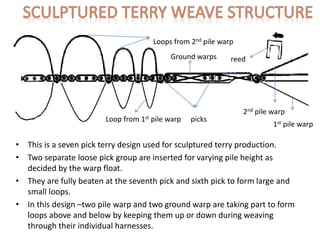

The document describes various types of pile fabrics, focusing on terry cloth production and its unique weaving methods. It details the processes involved in creating terry fabrics, including the use of loop and cut pile techniques, the role of specialized weaving machines, and how fabric characteristics can be altered during and after weaving. Additionally, it mentions specific machinery and references for further reading.