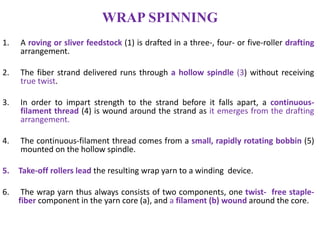

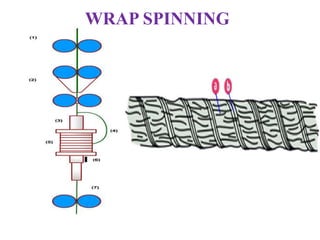

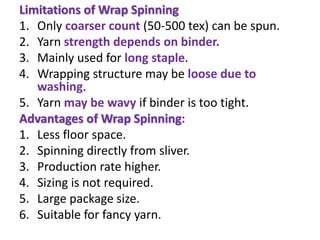

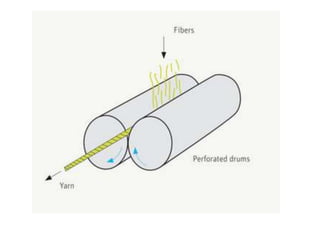

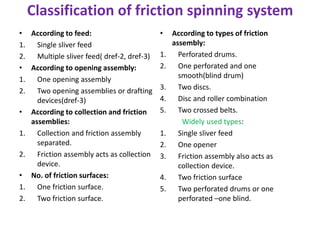

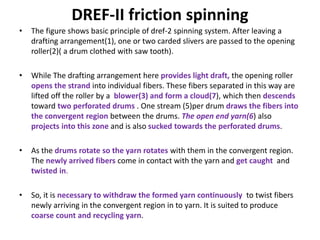

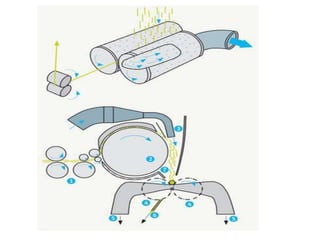

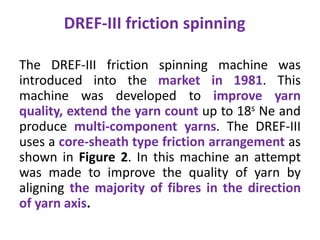

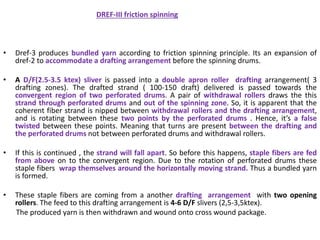

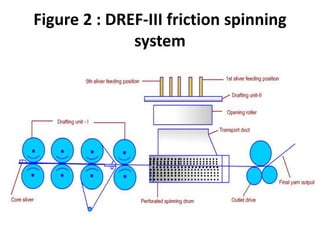

The document discusses wrap spinning and friction spinning systems for yarn production, including descriptions of the wrap spinning and DREF friction spinning processes, their advantages and limitations, end uses of wrap yarns, manufacturers of wrap spinning machines, classifications of friction spinning systems, and features of the DREF-II and DREF-III friction spinning machines.