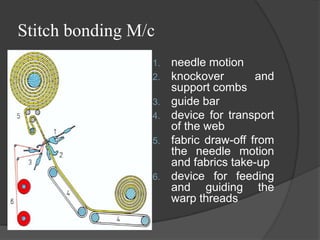

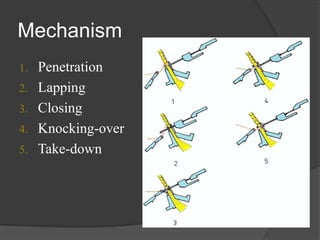

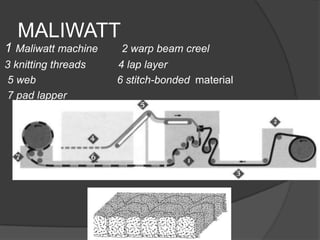

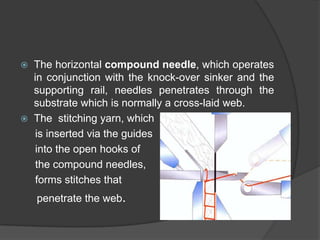

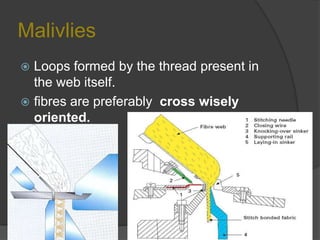

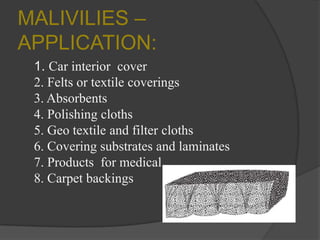

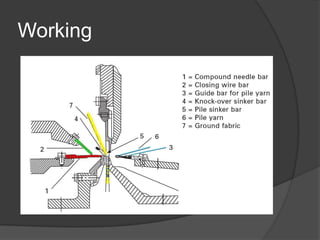

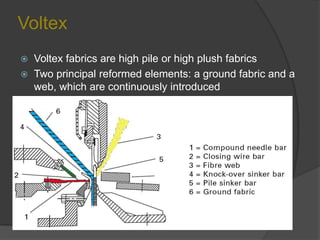

Stitch bonding is a hybrid textile manufacturing technique that combines elements of nonwoven, sewing, and knitting processes. It involves locking layers of cross-laid fibers or nonwoven fabrics into a warp knit structure using pointed needles that penetrate the layers and insert stitching yarn. There are several stitch bonding systems that differ in whether they use a separate stitching thread or form loops within the layers themselves. Common applications of stitch bonded fabrics include upholstery, mattress coverings, cleaning cloths, and industrial materials like filters or insulation.