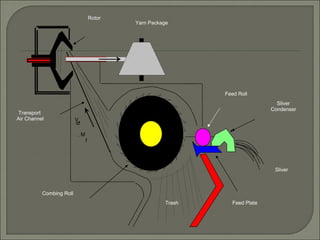

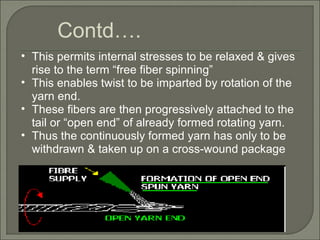

Open-end spinning or rotor spinning is a technology for creating yarn without using a spindle. It separates fiber slivers into single fibers using an air stream and deposits them onto a collecting surface where they are twisted into yarn as it is drawn off. The principle is similar to a clothes dryer where individual sheets can be pulled out while twisting together. Fibers are fed onto the collecting surface which is continuously moving, aligning the fibers and twisting them into a thread that is wound onto a bobbin. Open-end spinning allows internal fiber stresses to relax and imparts twist directly onto the yarn end rather than drafting fibers. This makes the process faster and less labor intensive than ring spinning.