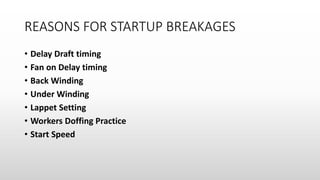

This document discusses start up breakages on ring spinning frames and methods to control them. It defines start up breakages as thread breaks that occur after starting the machine or after doffing bobbins. Potential causes include issues with drafting timing, back winding, under winding, traveller settings, doffing practices, start speed, suction, gear meshing, undrafted material, and more. Methods are provided to measure start up breakage percentage and suggestions for remedies like changing travelers periodically, adjusting ring and spindle settings, checking material quality, and optimizing climate and cleaning procedures.