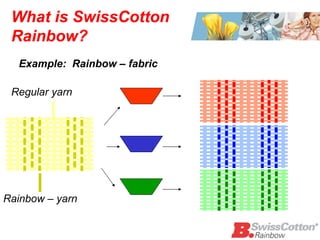

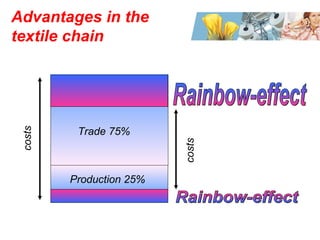

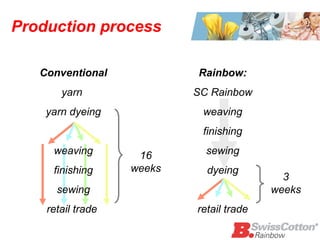

The document describes Rainbow-technology, which uses yarn with increased dye affinity to allow patterns and colors to be added after weaving, without needing to dye yarn or hold excess inventory. This allows for more flexible and rapid production of fashion items in various colors. The technology reduces costs for retailers and manufacturers by minimizing inventory and lead times. It also allows for small production runs of fashionable colored items.