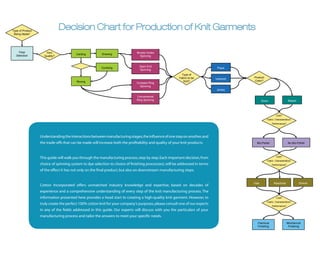

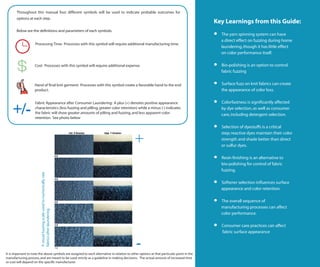

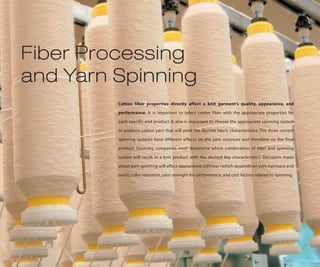

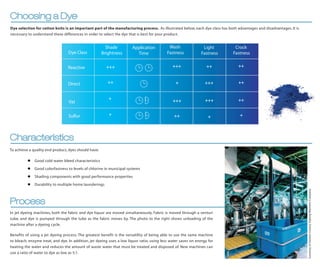

This document provides a guide to improving cotton knit products by making informed decisions at each stage of manufacturing. It discusses fiber selection, yarn spinning systems, fabric construction, preparation, dyeing, and finishing processes. The quality of the final garment is directly affected by these decisions. Understanding how each step influences subsequent stages can help reduce costs, deliver higher quality products with fewer returns, and develop value-added products. The guide analyzes options at each stage and their effects on time, cost, and fabric characteristics. Consultation with experts is recommended to tailor the process to specific needs.