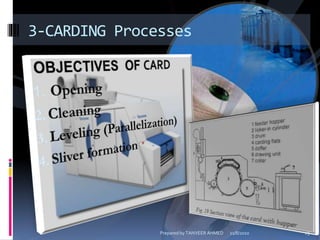

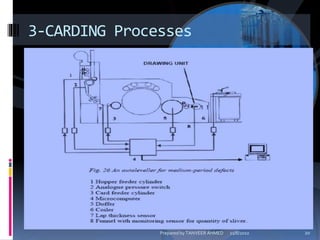

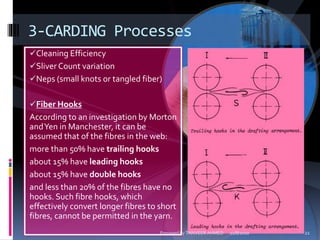

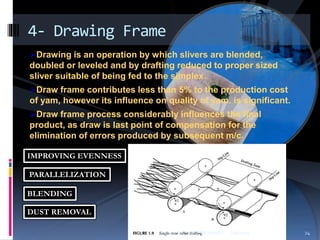

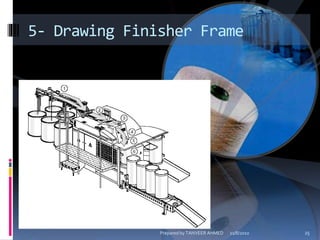

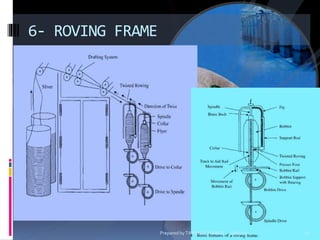

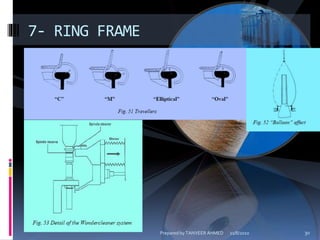

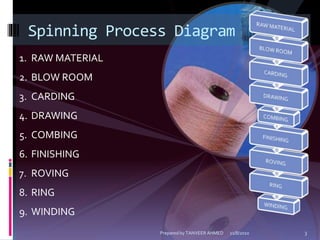

The document discusses textile spinning and quality control processes. It describes the key steps in textile spinning which include: yarn production from staple fibers using drawing and twisting; filament yarn production by forcing fiber-forming substances through spinnerets. The main processes are: blowroom preparation, carding, drawing, roving and ring spinning. Quality is ensured through testing of raw materials and processes. Fiber properties like length, strength and uniformity are evaluated. Machines are also tested to minimize count variations and improve yarn evenness and strength in the final product.

![TEXTILE FiberTesting:

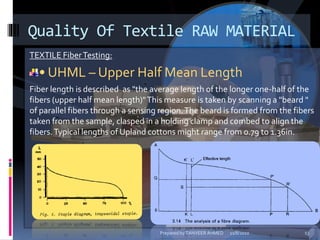

• UI – Uniformity Index

Length uniformity or uniformity ratio is determined as " a ratio between

the mean length and the upper half mean length of the fibers and is

expressed as a percentage“

with the Fibrogram.The span lengths at given percentages of fibres are

usually measured; the 2.5% span length is considered to correlate with

the classer's staple length. From the 50% span length and the 2.5% span

length.

a uniformity index can be calculated:

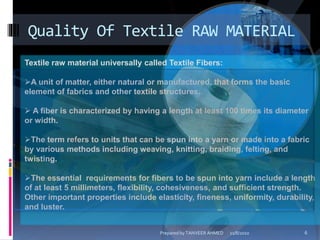

Quality Of Textile RAW MATERIAL

LENGTH

UNIFORMITY

UNIFORMITY

INDEX [%]

Very High >85

High 83-85

Intermediate 80-82

Low 77-79

Very Low <77

11/8/2010 15Prepared by TANVEER AHMED](https://image.slidesharecdn.com/textilespinning-101116010411-phpapp01/85/Textile-spinning-15-320.jpg)