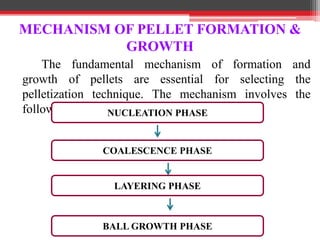

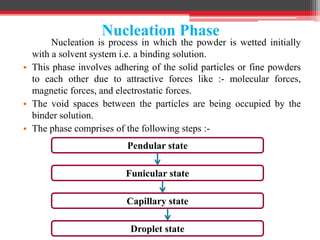

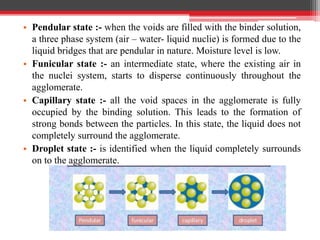

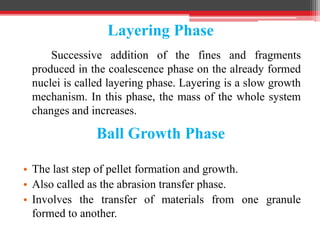

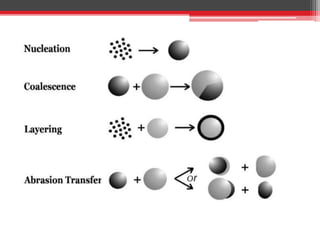

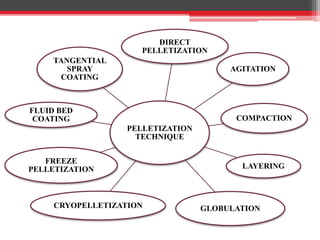

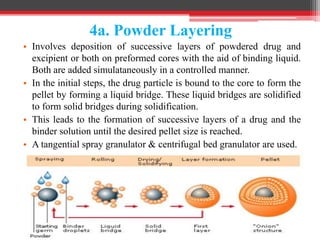

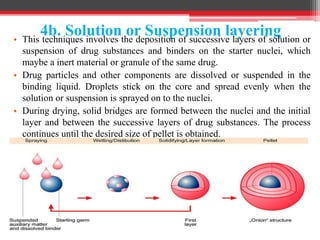

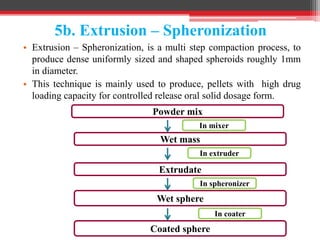

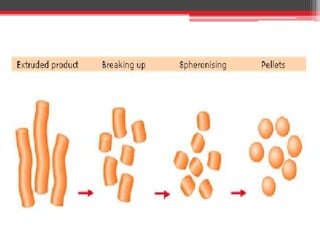

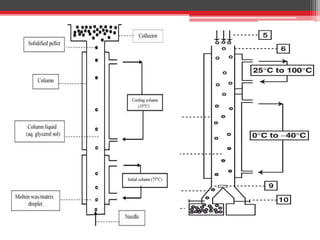

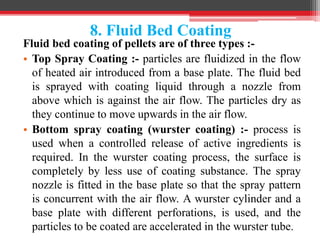

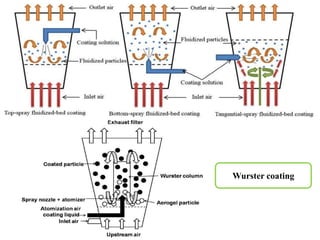

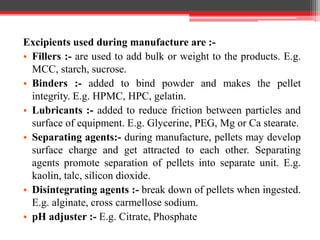

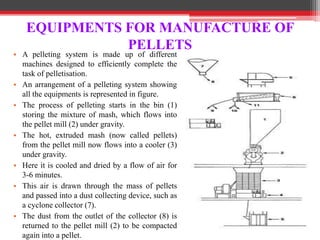

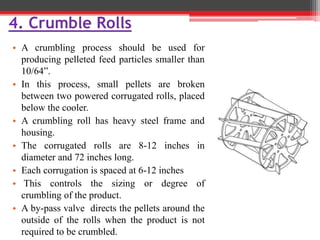

The document discusses the formulation and industrial pharmacy of pellets, which are small spherical units made from agglomerating fine powders or granules with excipients. It covers the advantages and disadvantages of pelletization, various pelletization techniques, mechanisms of pellet formation, and the necessary equipment for manufacturing pellets. Additionally, it details formulation requirements, including excipients and processing equipment, emphasizing the complexities and technical demands of pellet production.