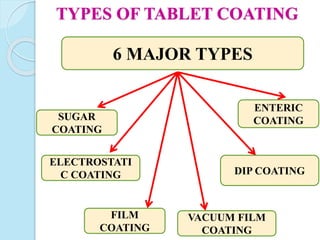

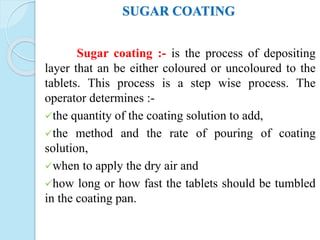

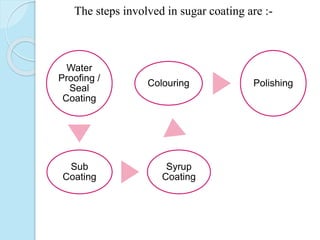

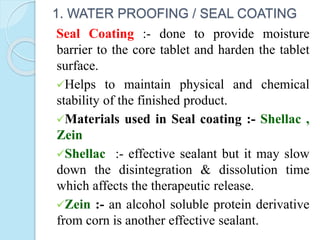

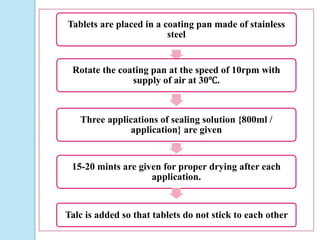

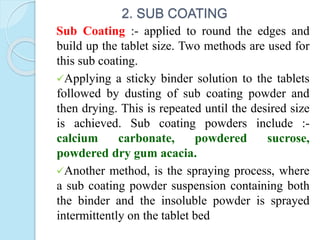

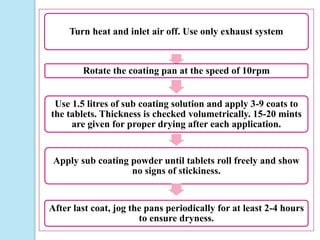

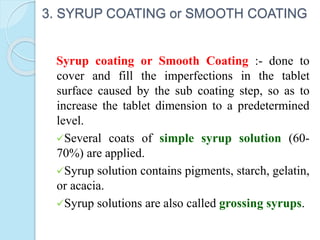

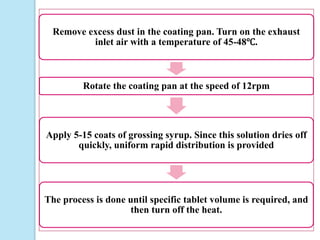

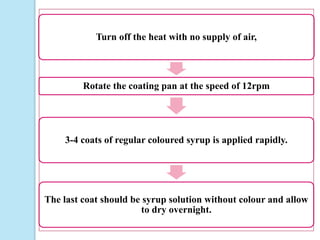

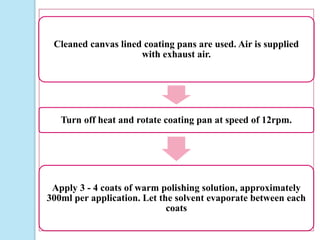

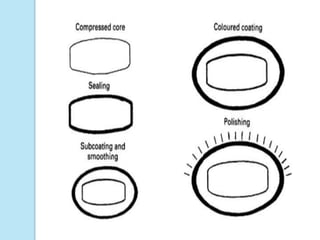

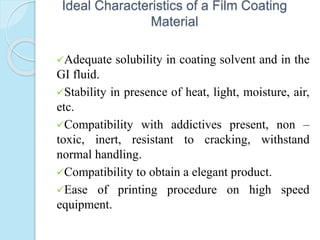

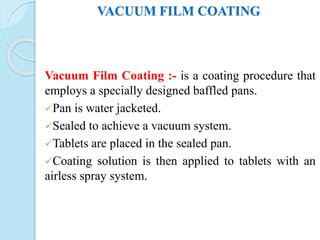

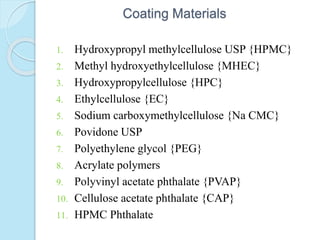

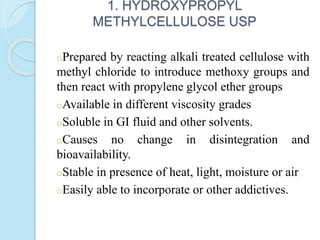

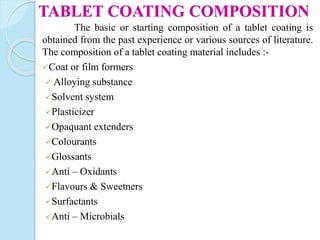

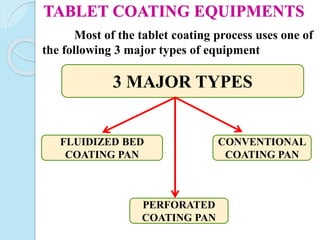

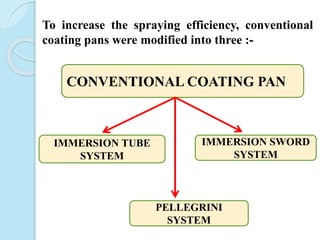

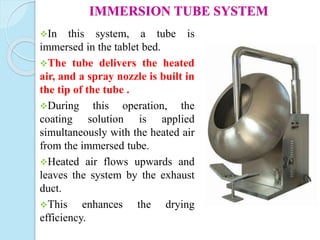

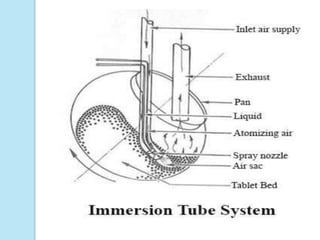

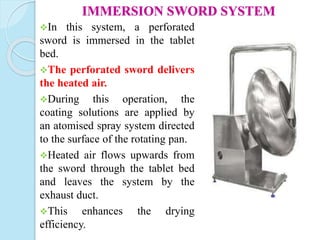

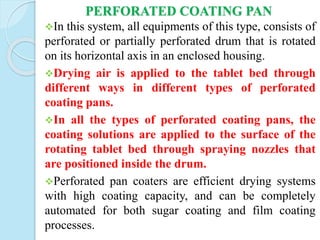

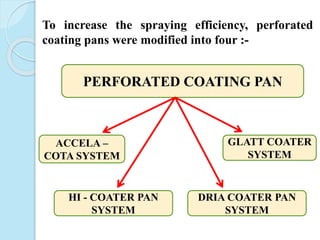

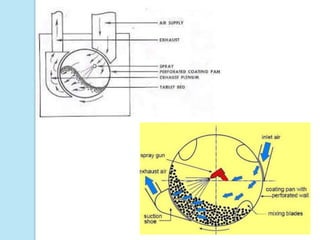

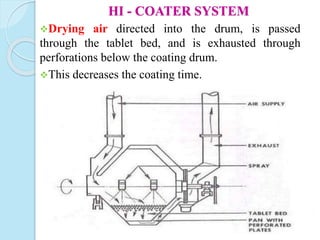

This document discusses tablet coating, which involves covering tablet surfaces with a polymeric film to provide benefits like masking taste, protecting drugs, and controlling drug release. It describes the main types of tablet coating - sugar coating, film coating, enteric coating, vacuum film coating, electrostatic coating, and dip coating. For each coating type, it outlines the basic process and materials used. The document also explains the need for tablet coating and lists the ideal characteristics of coating materials.