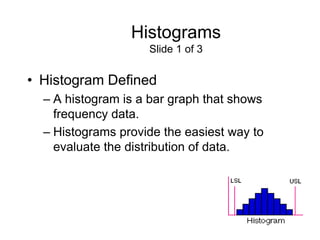

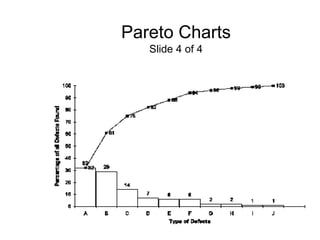

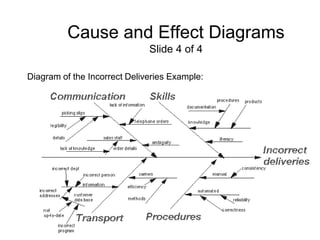

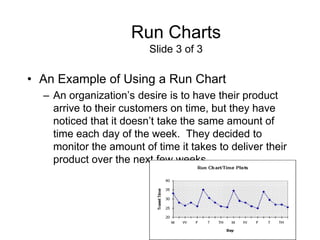

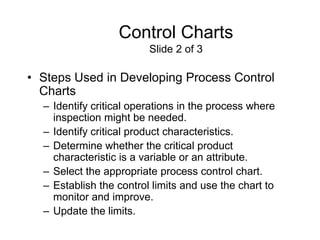

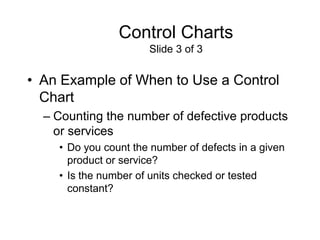

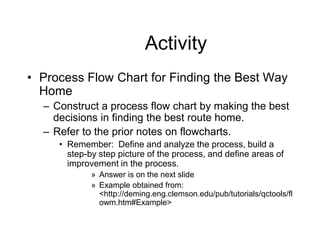

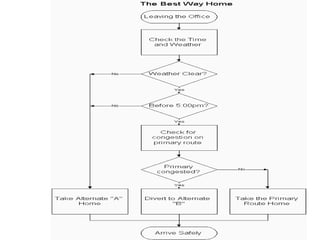

The document discusses the seven quality tools developed by Kaoru Ishikawa: histograms, Pareto charts, cause and effect diagrams, run charts, scatter diagrams, flow charts, and control charts. It provides descriptions and examples of how to construct and use each tool, including slides explaining histograms, Pareto charts, cause and effect diagrams, scatter diagrams, run charts, flow charts, and control charts. The tools are visual aids to analyze processes, identify problems, determine relationships between variables, and monitor quality.