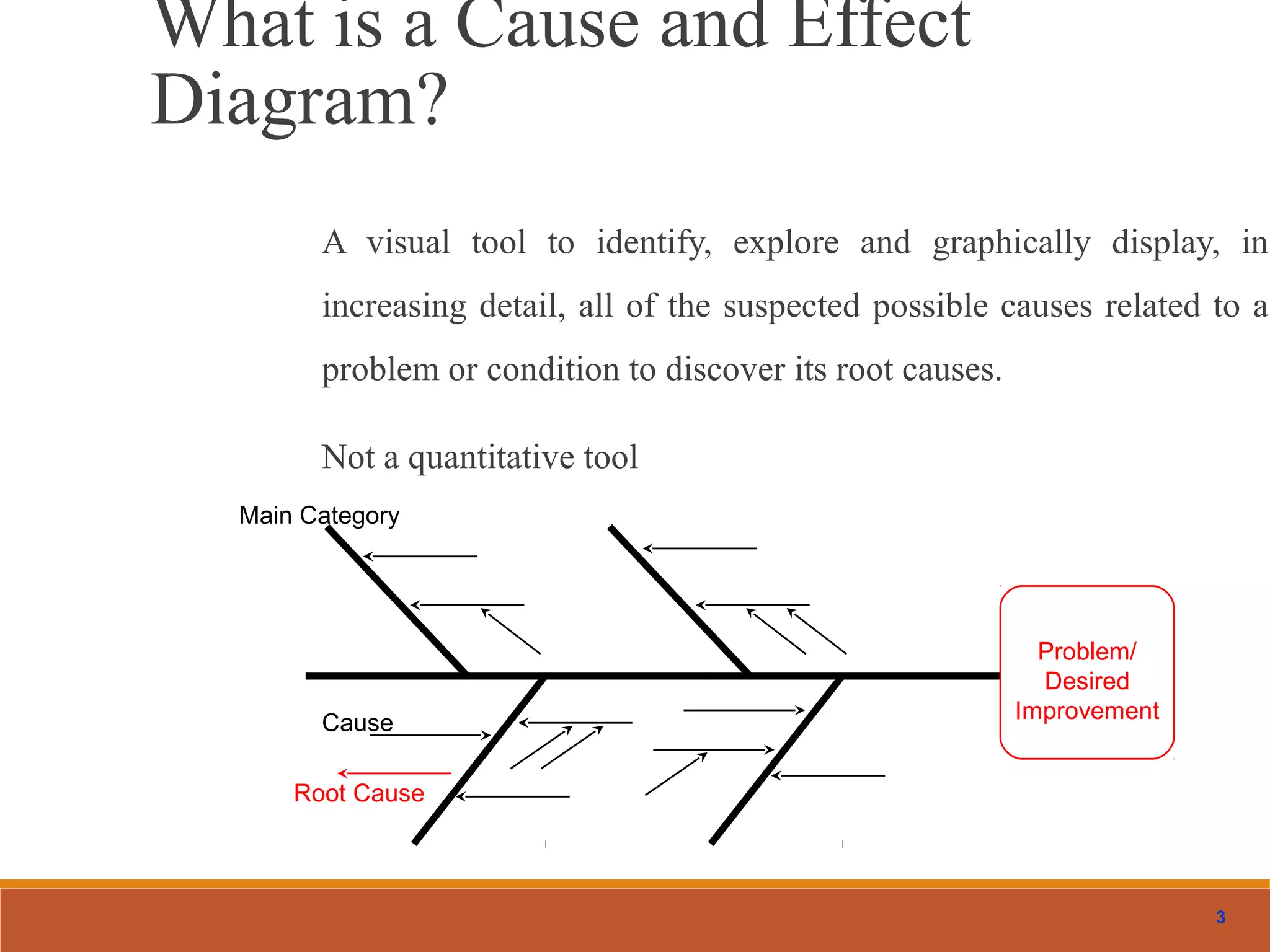

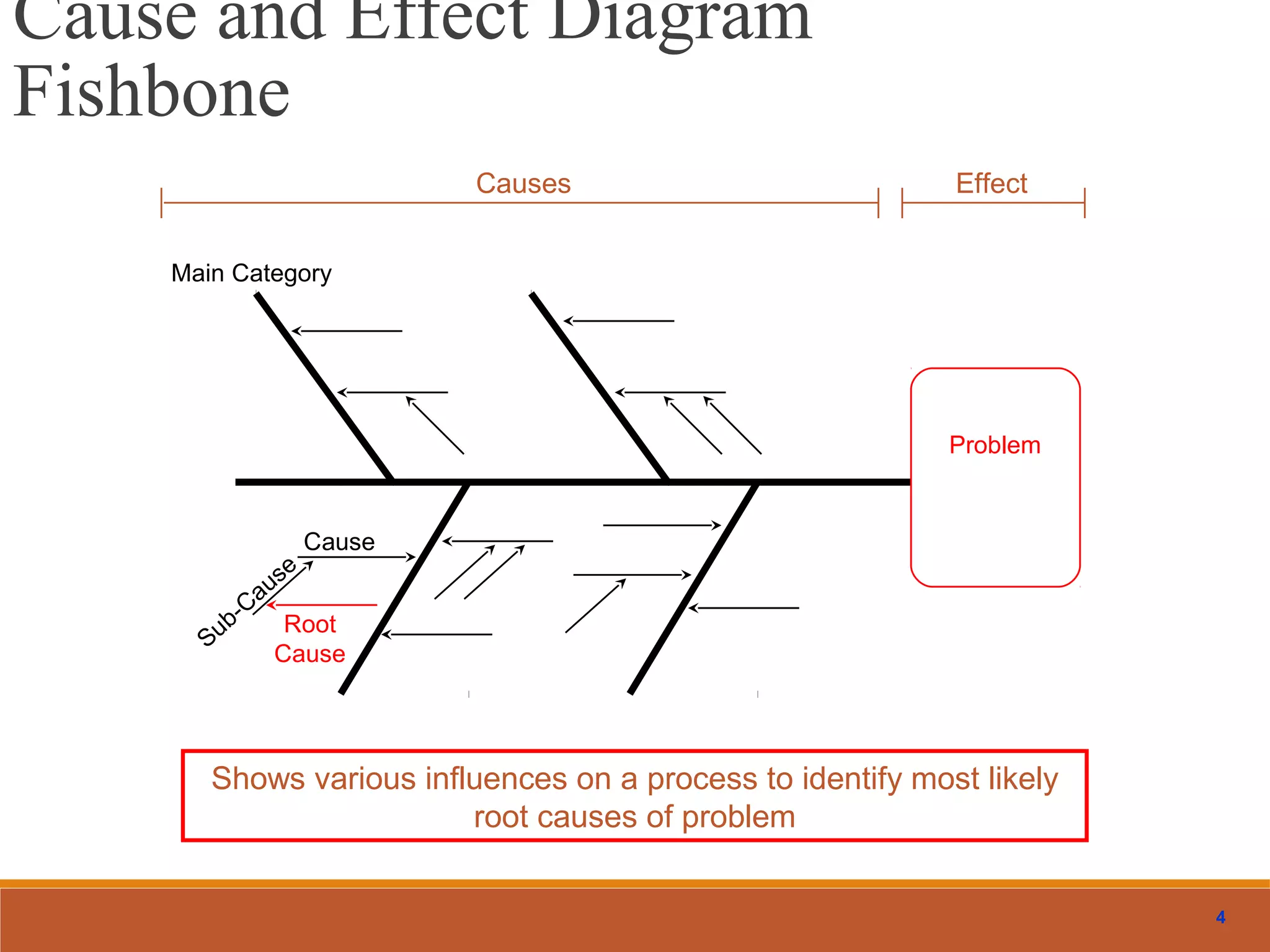

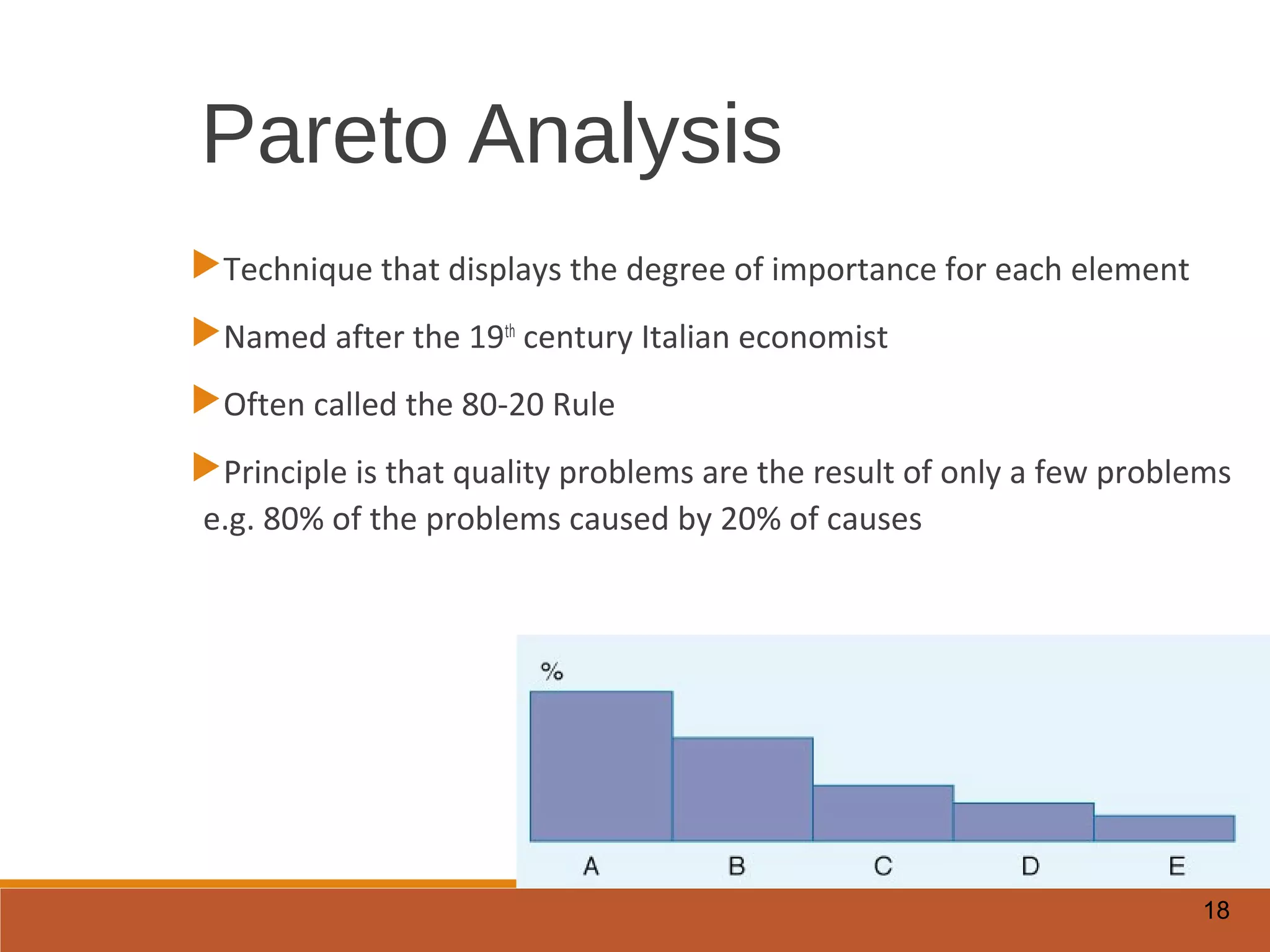

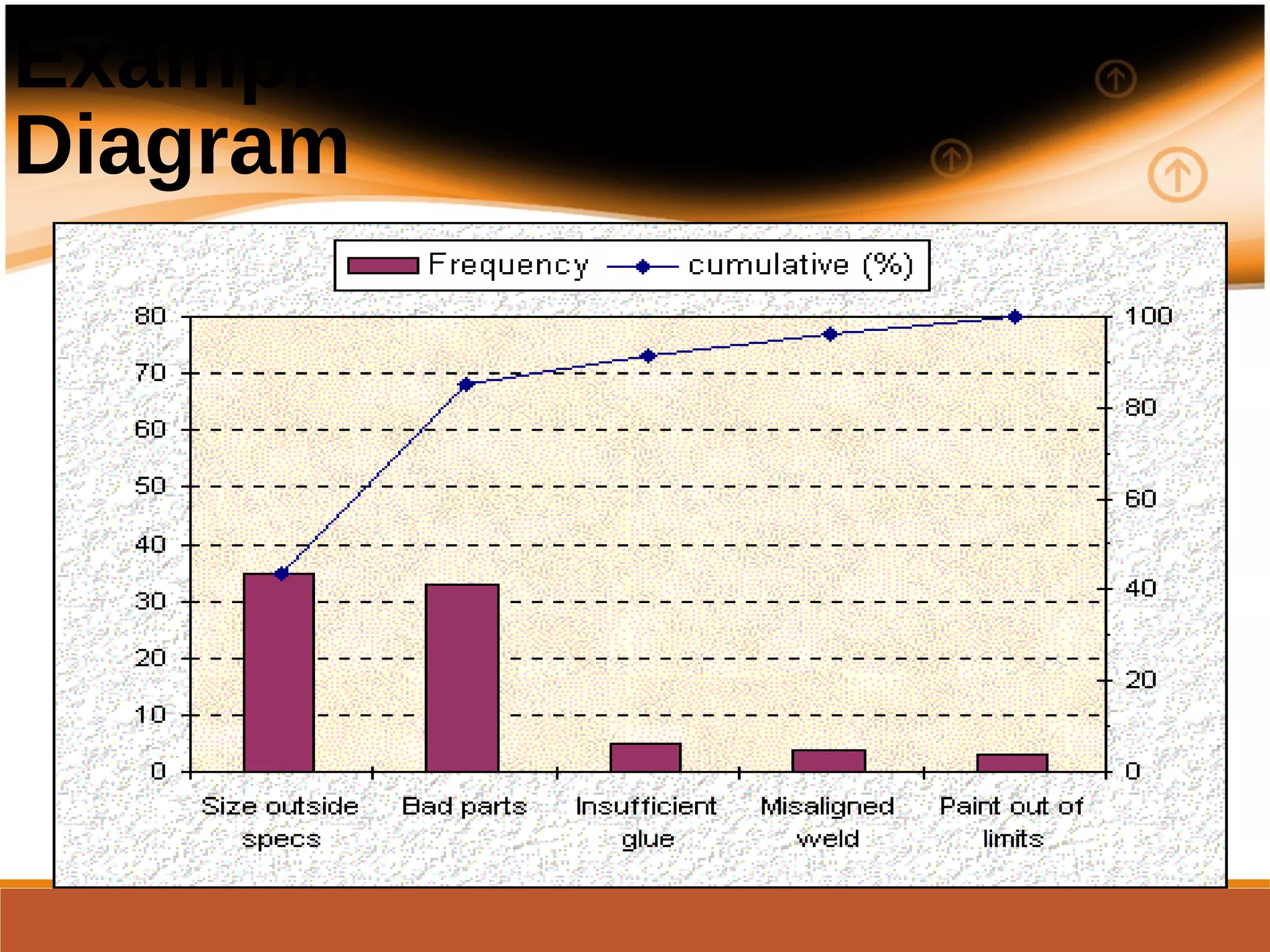

The document provides information on the basic seven tools of quality: cause-and-effect diagrams, flowcharts, checklists, control charts, scatter diagrams, Pareto analysis, and histograms. It defines each tool and provides an example of some. Cause-and-effect diagrams help identify potential factors causing a problem or condition. Flowcharts show the sequence of steps in a process. Checklists identify quality problems. Control charts show if a process is in or out of control. Scatter diagrams illustrate relationships between variables. Pareto analysis separates vital few causes from trivial many. Histograms show the variation in data.