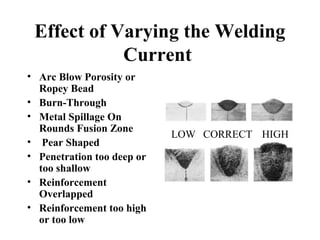

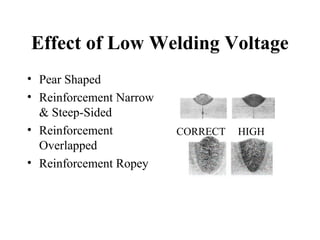

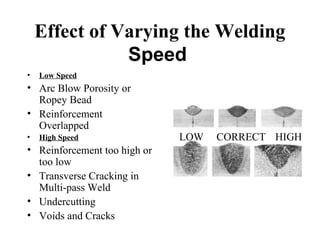

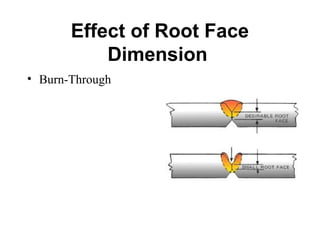

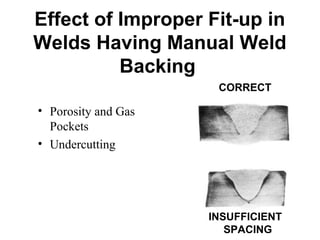

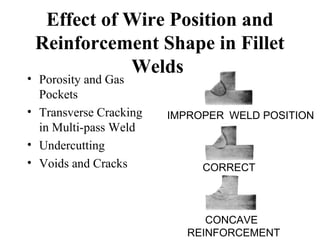

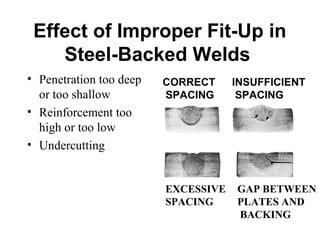

The document discusses the effects of various welding parameters and techniques on weld quality. It identifies issues such as porosity, undercutting, improper reinforcement, burn-through, and cracking that can occur when parameters like current, voltage, speed, beveling, fit-up, wire position, and granular material depth are not properly set or techniques not properly followed. Maintaining correct welding parameters and techniques is important to produce welds without defects.