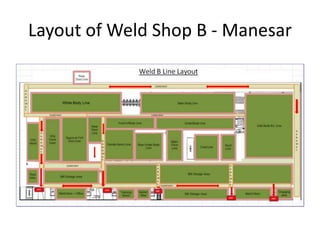

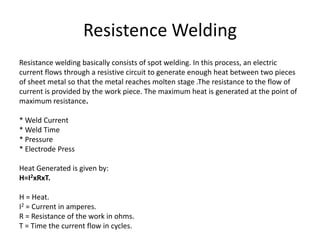

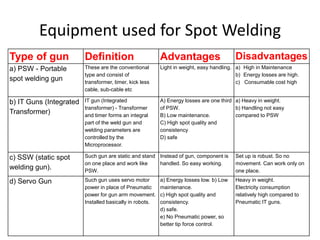

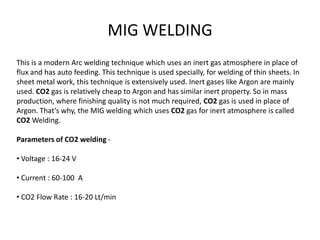

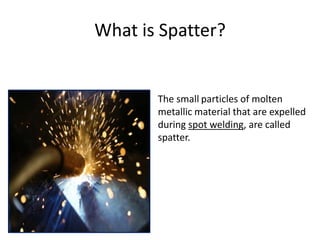

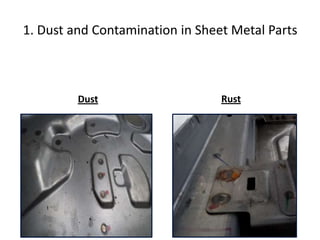

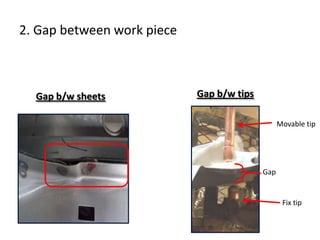

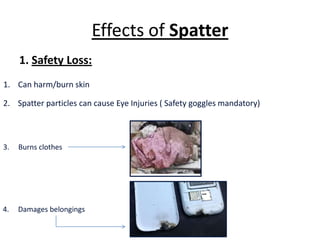

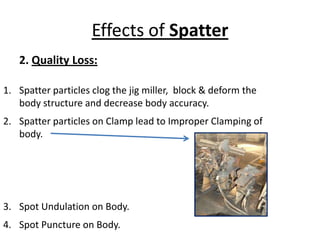

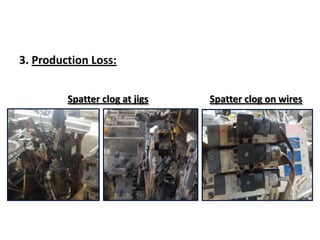

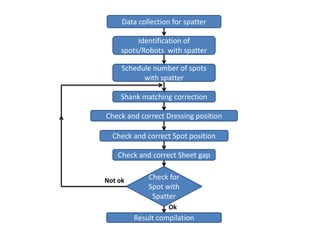

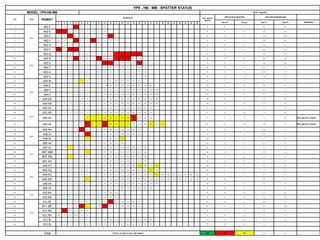

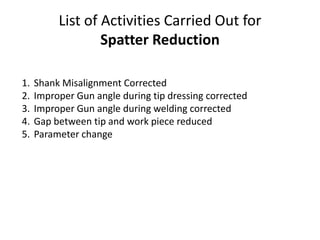

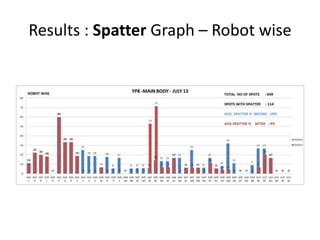

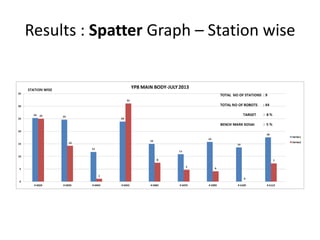

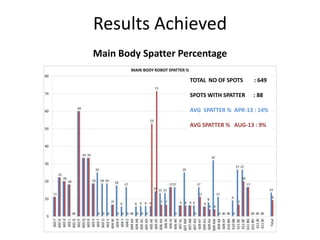

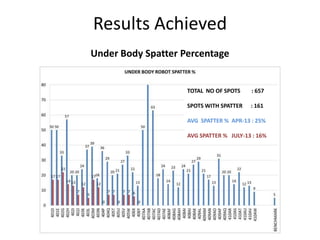

The document details a spatter reduction project conducted at Maruti Suzuki's Weld Shop B in Manesar, which aimed to enhance production efficiency and safety by addressing issues related to weld spatter. Key focuses included improving employee morale, increasing productivity, ensuring high-quality standards, and reducing costs through local sourcing and waste reduction. The project identified causes of spatter and implemented measures to monitor and reduce it, thereby enhancing safety, quality, and production capacity.