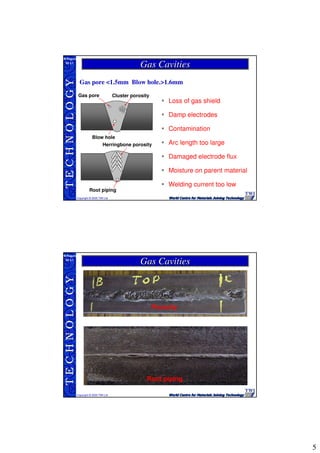

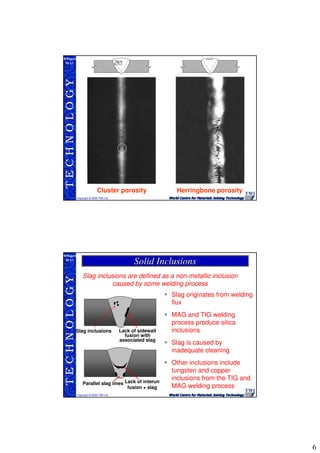

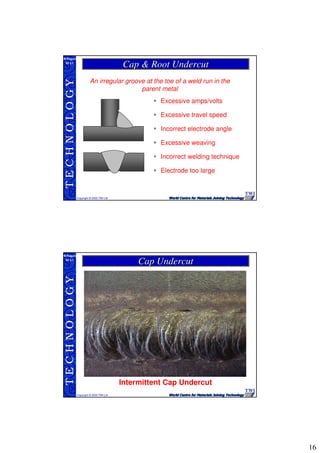

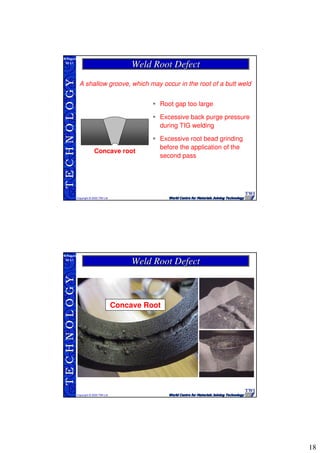

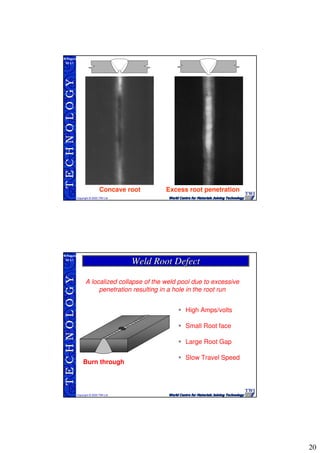

This document provides a classification and overview of common welding defects. It divides defects into three main categories: planar defects, linear volumetric defects, and non-planar defects. Examples of each type of defect are given. The document also describes specific defect types such as cracks, inclusions, lack of fusion, porosity, overlap, undercut and provides potential causes of each.